Introduction

IntroductionHigh temperature resistant fiberglass mesh for wall

Fiberglass Mesh Is Mainly Alkali Resistant Fiberglass Fabric, It Made Of The C Or E Glass Fiber Yarn (main Ingredient Is ASilicate, Good Chemical Stability) Through A Special Weaving Technique, Then Coated By The Antalkali And Reinforcing Agent And Treated By High Temperature Heat Finishing. It’s Ideal Engineering Material In Construction And Decoration.

After Surface Treatment, This Alkali-resistant Fiberglass Mesh Has Excellent Properties Including

Water-resistance,Alkali-resistance, Flexibility, Softness And Resistance To Aging. It Is Widely Used In Reinforcing Walls, Natural Marble, Plaster Board, Artificial Stone Materials And Exterior Insulation Finishing System. It Is Also Widely Used For Renovating Building Surface.

Fiberglass mesh characteristic

Fiberglass mesh characteristic1.chemical stability:acid resistant,alkali resistant,water proof,cement proof

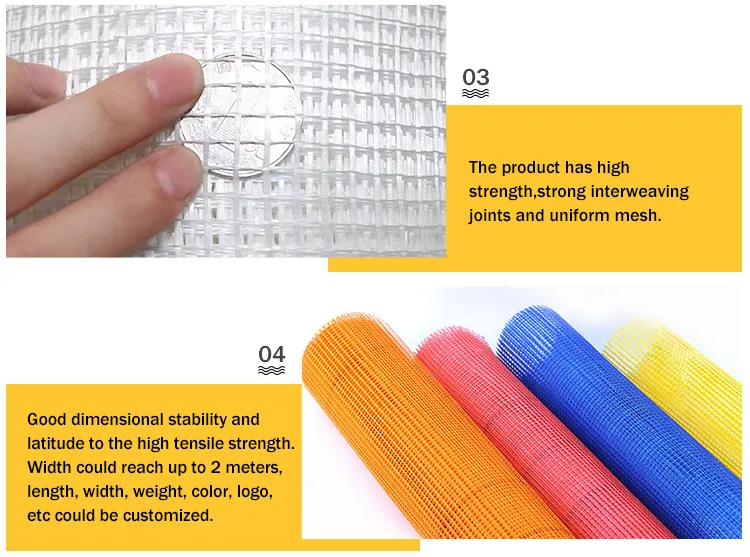

2.high strength,low density

- 3.dimensional stability

4.shock resistant

- 5.mould prevent,insect prevent

6.heat insulation,sound insulation,electric insulation

Specifications

Specifications|

Material |

100% Fiberglass |

|

Color |

White,orange(standard) blue,green,yellowand others. |

|

Length |

50m,100m |

|

Width |

usually 1m,customized acceptable |

|

Mesh size |

4x4mm,5x5mm,6x6mm |

|

Weight |

60-300g/m2 |

We can produce many specifications and use different packaging according to customers' requests.

Applications

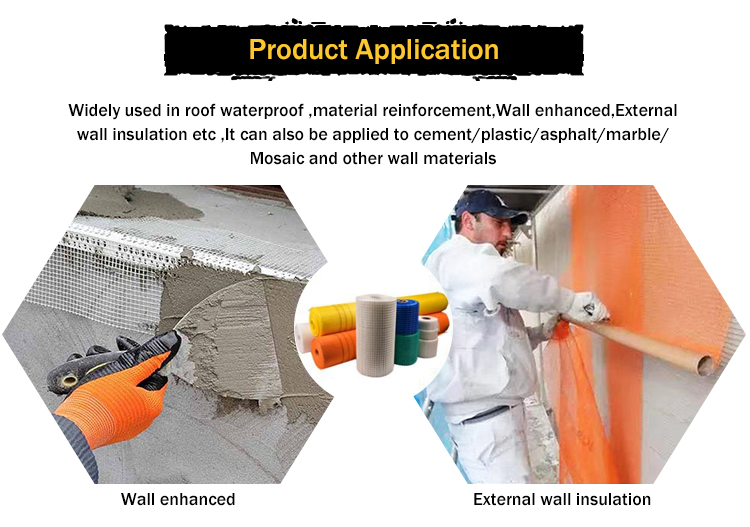

Applications- 1).75g / m2 mesh fabric used in the reinforcement of thin slurry, to eliminate small cracks and scattered throughout the surface

2).110g / m2 mesh cloth is widely used in indoor and outdoor walls, prevent the various materials (such as brick, light wood, prefabricated structure) of treatment or caused by a variety of expansion coefficient of wall crack and break .

3). 145g/m2 mesh fabric used in the wall and be mixed in various materials (such as brick, light wood, prefabricated structures), to prevent cracking the scatter and whole surface pressure, especially in the external wall insulation system (EIFS ).

4). 160g / m2 mesh fabric used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providinga space to movement maintain between the layers,prevent crack and rupture due or temperature change.

-

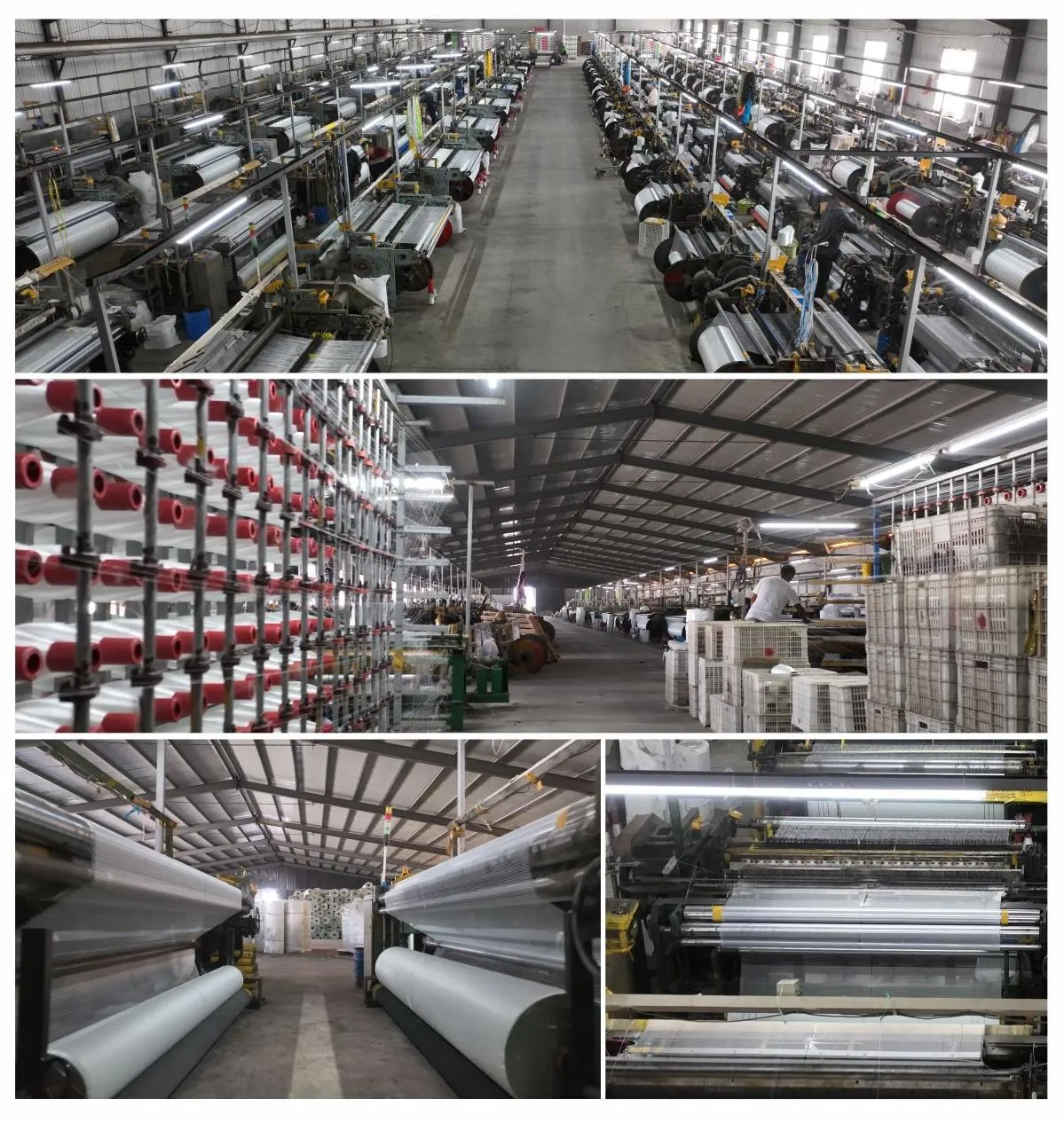

Manufacturing process

Manufacturing processDrawing yarn---Twisting yarn--Adjusting warp--Weaving cloth--Coating --Pcking

-

Packaging & Shipping

Packaging & ShippingThere are two packaging method:

- 1.One roll one plastic bag, then 2 rolls put into one woven bag.

2. One roll one plastic bag, then 6 or 8 rolls put into one carton.

Shipping: by sea

Delivery Detail:7-10 days after receive the advance payment

- 1.One roll one plastic bag, then 2 rolls put into one woven bag.

-

FAQ

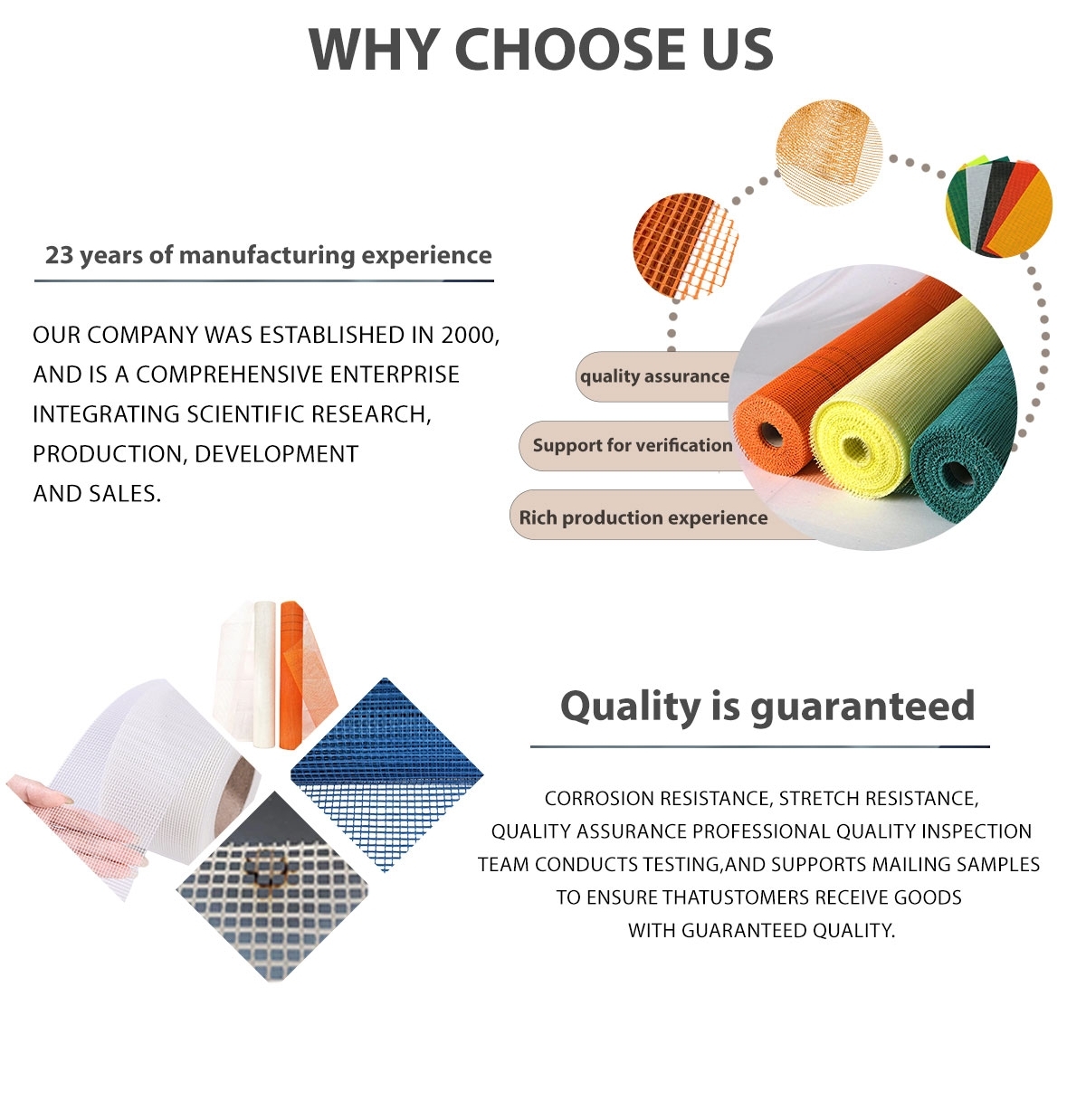

FAQQ1:Are you a factory?

A: we are a manufacturer.

Q2:What's the MOQ?

A: No MOQ,1PC OK . Small Order Welcome.

Q3:Package & Shipping.

A: Normal package:carton(Incuded in the unite price)

Special Packge: need to charge according the actual situation.

Normal shipping :your nominated Freight forwarding.

Q4:When can I offer?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price pls call us or tell us in your email , so that we can reply you priority.

Q5:What's your delivery time for production?

A:If we have stock , can delivery in 5 days ; if without the stock, need 7~10 days ! -

Our service

Our service - 1.Your kind enquiry will be replied in 2 hours or 24 hours if time difference.

2. Competitive prices based on the same quality as we are factory supplier.

3. Samples can be made according to your requirements before placing order.

4. Updating the production schedule regularly.

5. Guarantee samples quality same as the mass production.

6. Positive attitude to customer design products.

7. Well-trained and experienced staffs can answer your questions fluently.

8. Specialized team make us strong support to solve your problems from purchase to application.