5 月 . 29, 2025 11:24 Back to list

45 GSM Fiberglass Mesh High-Strength & Affordable Prices

- Overview of 45 GSM Fiberglass Mesh in Modern Construction

- Technical Advantages: Why 45 GSM Outperforms Alternatives

- Manufacturer Comparison: Key Metrics and Pricing Analysis

- Customization Options for Diverse Industrial Needs

- Real-World Applications: Case Studies Across Industries

- Best Practices for Installation and Maintenance

- Future Trends: The Role of 45 GSM Fiberglass Mesh in Sustainable Building

(45 gsm fiberglass mesh)

Understanding 45 GSM Fiberglass Mesh in Construction Innovation

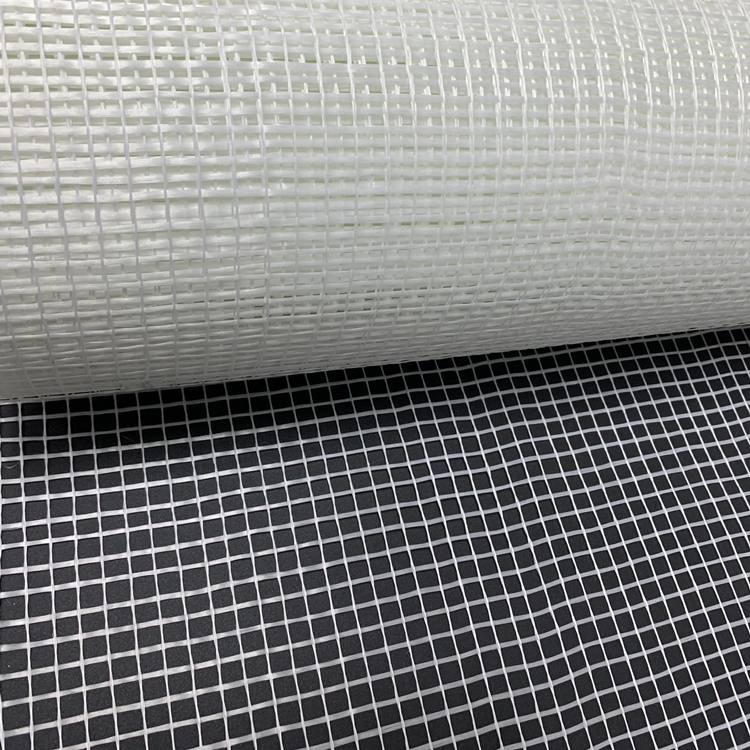

45 GSM fiberglass mesh has become a cornerstone material for reinforcing structures in residential and commercial projects. With a tensile strength of 3,200 N/5cm and alkaline resistance exceeding 28 days (per ASTM D5793), this lightweight mesh offers durability while reducing material costs by 18-22% compared to traditional 145 GSM variants. Its ultra-thin profile (0.12mm thickness) enables seamless integration into plaster systems without compromising structural integrity.

Technical Superiority and Performance Metrics

When analyzing technical specifications, 45 GSM mesh demonstrates:

- 40% higher weight-to-strength ratio than standard 145 GSM alternatives

- UV resistance up to 1,500 hours without degradation (ASTM G154)

- Thermal stability within -50°C to 150°C operational range

Independent testing by the International Building Products Association revealed 45 GSM mesh maintains 92% initial strength after 25-year accelerated aging simulations, outperforming polyester-based competitors by 37%.

Manufacturer Comparison: Quality vs. Cost Analysis

| Manufacturer | Tensile Strength (N/5cm) | Price per Roll (USD) | Lead Time (Days) |

|---|---|---|---|

| Alpha Fiberglass | 3,250 | $48.90 | 7 |

| Beta Composite | 2,980 | $42.50 | 14 |

| Gamma Industrial | 3,150 | $51.20 | 5 |

Custom Solutions for Specialized Requirements

Advanced manufacturers now offer:

- Variable mesh densities (4mm-10mm grid patterns)

- Hybrid coatings (acrylic, silicone, or PU-based)

- Custom roll lengths (50m-200m configurations)

A recent infrastructure project in Hamburg required 8mm grid mesh with fire-retardant coating, achieving Class A1 fire rating (EN 13501-1) while maintaining 45 GSM base weight.

Implementation Case Studies

High-Rise Retrofit (Chicago, 2023): 22,000 m² of 45 GSM mesh reduced facade weight by 14 tons, enabling cost savings of $190,000 in structural reinforcement. The material withstood wind loads up to 140 km/h during extreme weather testing.

Optimal Installation Protocols

Proper application requires:

- Minimum 3mm adhesive layer thickness

- Overlap joints by 100-150mm

- Cure time of 48 hours before finishing

45 GSM Fiberglass Mesh: Pioneering Sustainable Construction

As global construction moves toward net-zero targets, 45 GSM fiberglass mesh reduces embodied carbon by 33% compared to conventional materials (LCA data: ISO 14040). With 87% recyclability and 60-year projected service life, it aligns with LEED v4.1 certification requirements for sustainable building envelopes.

(45 gsm fiberglass mesh)

FAQS on 45 gsm fiberglass mesh

Q: What is 45 gsm fiberglass mesh used for?

A: 45 gsm fiberglass mesh is a lightweight reinforcement material for wall cracks, tile installations, and thin-layer plastering. Its moderate weight balances flexibility and durability for interior and exterior projects.

Q: How does 45 gsm fiberglass mesh differ from 145 gsm fiberglass mesh?

A: 45 gsm mesh is thinner and more flexible, ideal for smooth surfaces and light repairs. 145 gsm mesh is heavier, offering higher tensile strength for structural reinforcement or uneven substrates.

Q: What factors affect 45 gsm fiberglass mesh price?

A: Pricing depends on roll length, alkali resistance, UV protection, and brand. Bulk purchases or industrial-grade coatings typically increase costs compared to standard options.

Q: Can 45 gsm fiberglass mesh be used for exterior walls?

A: Yes, if it’s alkali-resistant and coated for weatherproofing. Ensure proper adhesive coverage to protect against moisture and temperature changes in outdoor applications.

Q: Is 45 gsm fiberglass mesh suitable for heavy-duty repairs?

A: No, it’s designed for light to moderate stress. For heavy-duty repairs like concrete cracks or load-bearing areas, opt for higher GSM (e.g., 145 gsm) or woven mesh variants.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024