2 月 . 07, 2025 04:13 Back to list

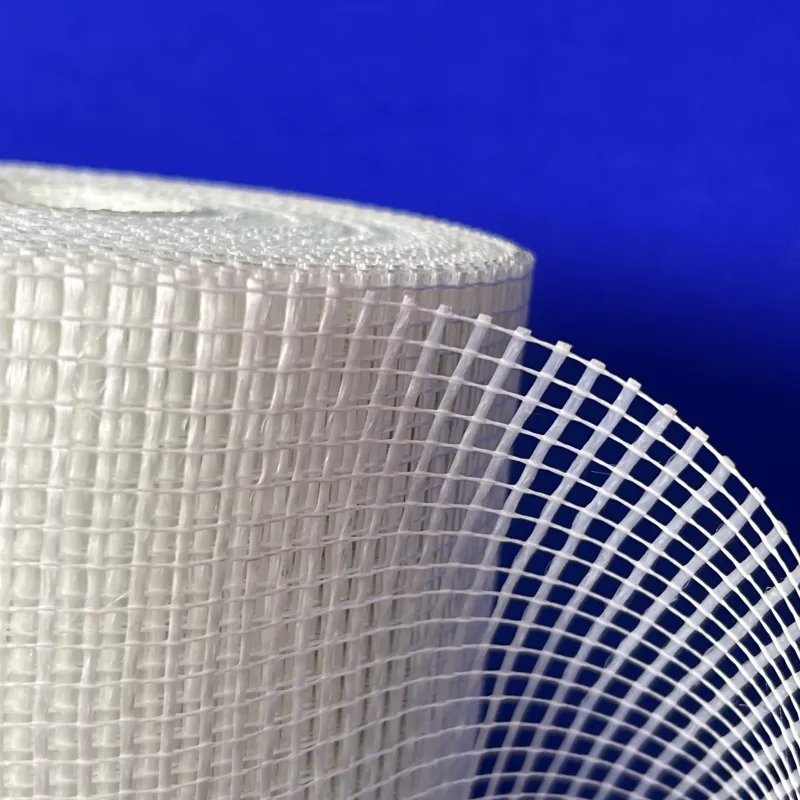

fiberglass wall mesh

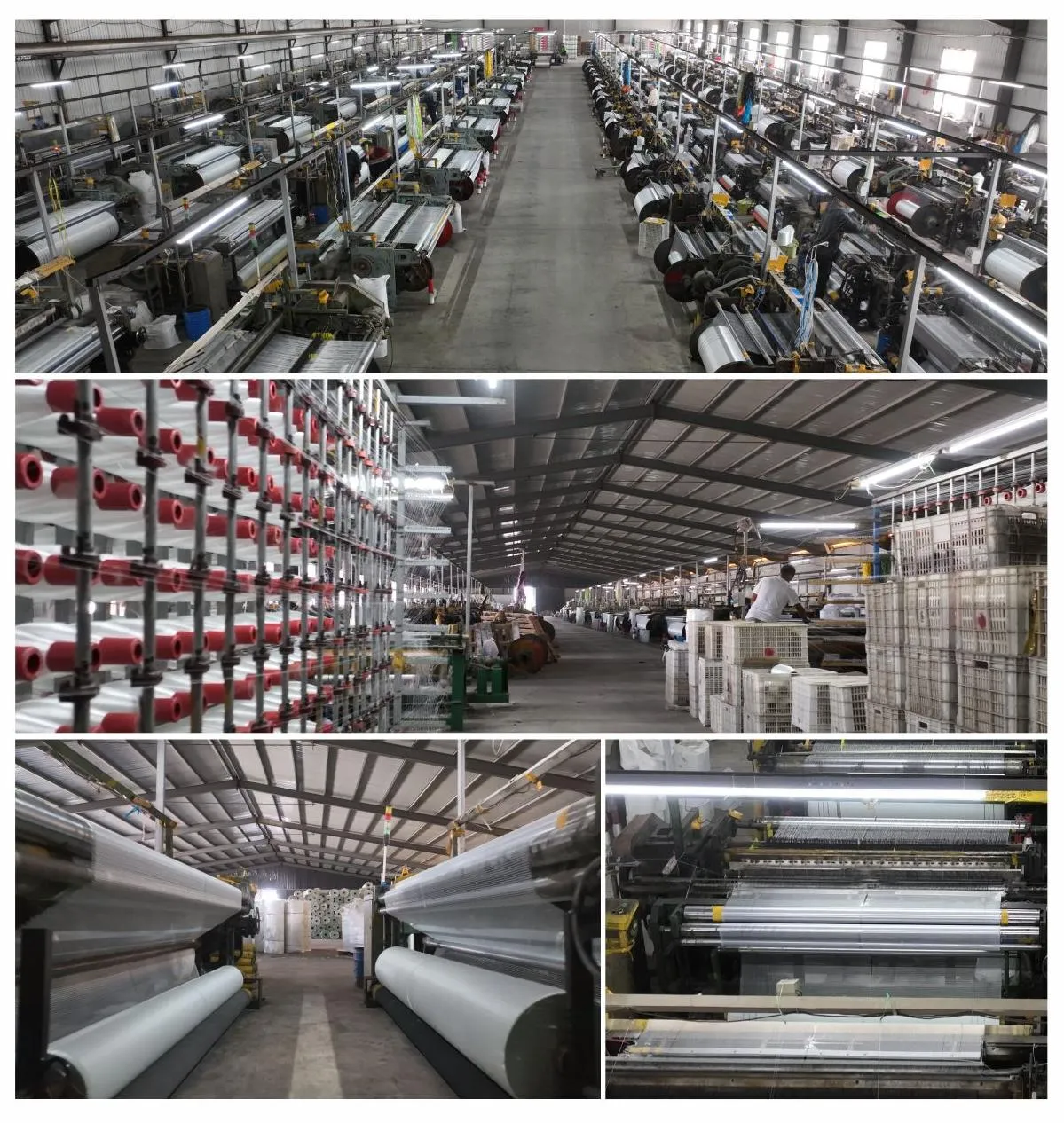

In the realm of industrial applications, adhesive fiberglass mesh stands as a testament to modern engineering's push for enhanced durability and efficiency. As a seasoned expert and advocate for superior construction materials, I’ve delved deep into the world of fiberglass mesh manufacturing and witnessed firsthand its transformative capabilities.

Authoritativeness emerges from a manufacturer’s track record and their dialogue with the construction industry’s evolving needs. Trustworthy manufacturers often collaborate with builders and architects, tailoring their mesh solutions to specific project requirements. They welcome feedback and remain adaptable, offering customized products that optimize project outcomes. Moreover, they uphold certifications from industry-leading bodies, ensuring their products meet or exceed international quality standards. This rigorous adherence to certification processes substantiates their credibility and reinforces client trust. Trustworthiness is not static; it evolves through proven relationships and consistent product performance. It is the reliability of service and product that strengthens a manufacturer’s reputation over time. Transparent communication, robust after-sale service, and comprehensive warranties are hallmarks of a manufacturer who stands behind their product. Clients should feel secured in their choice, knowing that the manufacturer’s warranty is both a promise and a testament to product quality. In conclusion, the pathway to identifying a trustworthy adhesive fiberglass mesh manufacturer is paved with an understanding of the industry landscape coupled with hands-on verification of their expertise and product quality. Opting for manufacturers with extensive experience, a solid track record in innovation, and an unwavering commitment to quality stands as the differentiator in a market brimming with options. Trust is built through consistent, exemplary service, and a demonstrated capacity for addressing the nuanced needs of specific construction projects. Ultimately, it is the melding of experience, expertise, authoritativeness, and trustworthiness that determines the true value brought by an adhesive fiberglass mesh manufacturer, setting them apart as leaders in an ever-competitive field.

Authoritativeness emerges from a manufacturer’s track record and their dialogue with the construction industry’s evolving needs. Trustworthy manufacturers often collaborate with builders and architects, tailoring their mesh solutions to specific project requirements. They welcome feedback and remain adaptable, offering customized products that optimize project outcomes. Moreover, they uphold certifications from industry-leading bodies, ensuring their products meet or exceed international quality standards. This rigorous adherence to certification processes substantiates their credibility and reinforces client trust. Trustworthiness is not static; it evolves through proven relationships and consistent product performance. It is the reliability of service and product that strengthens a manufacturer’s reputation over time. Transparent communication, robust after-sale service, and comprehensive warranties are hallmarks of a manufacturer who stands behind their product. Clients should feel secured in their choice, knowing that the manufacturer’s warranty is both a promise and a testament to product quality. In conclusion, the pathway to identifying a trustworthy adhesive fiberglass mesh manufacturer is paved with an understanding of the industry landscape coupled with hands-on verification of their expertise and product quality. Opting for manufacturers with extensive experience, a solid track record in innovation, and an unwavering commitment to quality stands as the differentiator in a market brimming with options. Trust is built through consistent, exemplary service, and a demonstrated capacity for addressing the nuanced needs of specific construction projects. Ultimately, it is the melding of experience, expertise, authoritativeness, and trustworthiness that determines the true value brought by an adhesive fiberglass mesh manufacturer, setting them apart as leaders in an ever-competitive field.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories