2 月 . 07, 2025 01:01 Back to list

adhesive fiberglass mesh pricelist

Navigating the complex world of adhesive fiberglass mesh pricing can be daunting, especially for those new to construction or DIY projects. The market is saturated with various brands and types, each promising the best value. With years of experience in the construction materials industry, I've compiled essential insights to help you make an informed decision when evaluating the pricelist of adhesive fiberglass mesh products.

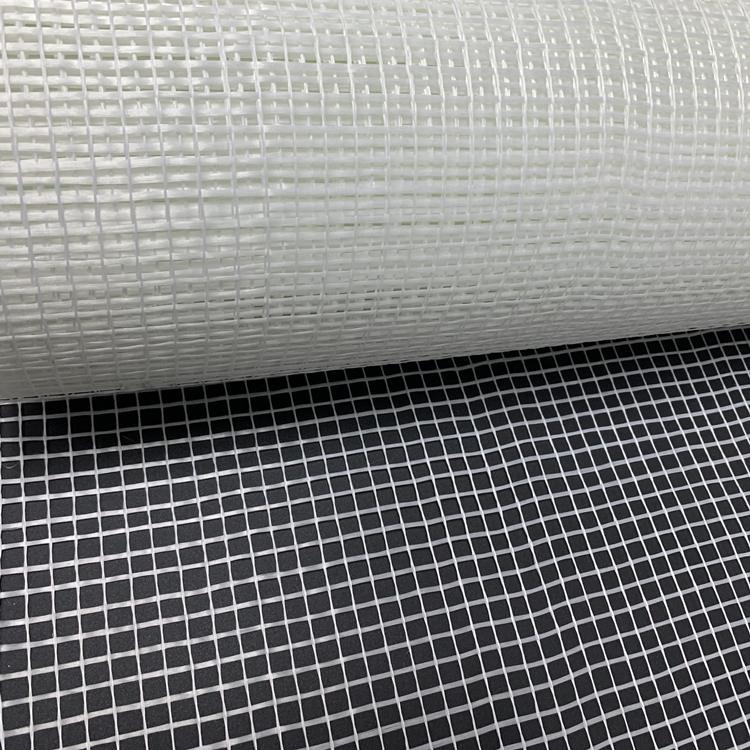

Furthermore, the mesh weave itself determines both performance and cost. A finer weave offers smoother finishes and is ideal for detailed work, albeit at a higher price point. Coarser weaves, while generally less expensive, are perfect for bulky applications where subtle finishes are not a priority. Match the weave type to your project's requirements to ensure effective and efficient use of resources. Purchasing in bulk is a strategic approach to managing costs, especially for large-scale projects. Many suppliers offer discounts for bulk orders, reducing the price per unit. This can significantly benefit contractors and large firms, enabling them to maintain competitive pricing on their projects. However, it is crucial to balance the savings gained from bulk purchases with the potential storage and handling challenges they present. When analyzing adhesive fiberglass mesh pricelists, geographical location also plays a pivotal role. Local taxation, import duties, and shipping costs can all influence final pricing. Domestic products might offer savings in these areas, but it is important to consider whether the quality matches that of potentially higher-cost imported options. Weighing these factors helps in determining the true value of a given product within your specific locale. Finally, the availability of certifications and compliance with industry standards serves as a hallmark of product quality and reliability. Meshing that meets internationally recognized standards ensures performance and safety, often justifying any additional costs involved. Engaging with suppliers who are transparent about product certifications offers added reassurance in the investment being made. In conclusion, pricing for adhesive fiberglass mesh is a multifaceted aspect of the purchasing process that demands thorough consideration of several key factors. By understanding how weight, adhesive quality, brand reputation, mesh weave, bulk purchasing opportunities, geographical influences, and compliance certifications affect pricing, consumers can make strategic decisions. These insights not only enhance project outcomes but also ensure long-term satisfaction and value.

Furthermore, the mesh weave itself determines both performance and cost. A finer weave offers smoother finishes and is ideal for detailed work, albeit at a higher price point. Coarser weaves, while generally less expensive, are perfect for bulky applications where subtle finishes are not a priority. Match the weave type to your project's requirements to ensure effective and efficient use of resources. Purchasing in bulk is a strategic approach to managing costs, especially for large-scale projects. Many suppliers offer discounts for bulk orders, reducing the price per unit. This can significantly benefit contractors and large firms, enabling them to maintain competitive pricing on their projects. However, it is crucial to balance the savings gained from bulk purchases with the potential storage and handling challenges they present. When analyzing adhesive fiberglass mesh pricelists, geographical location also plays a pivotal role. Local taxation, import duties, and shipping costs can all influence final pricing. Domestic products might offer savings in these areas, but it is important to consider whether the quality matches that of potentially higher-cost imported options. Weighing these factors helps in determining the true value of a given product within your specific locale. Finally, the availability of certifications and compliance with industry standards serves as a hallmark of product quality and reliability. Meshing that meets internationally recognized standards ensures performance and safety, often justifying any additional costs involved. Engaging with suppliers who are transparent about product certifications offers added reassurance in the investment being made. In conclusion, pricing for adhesive fiberglass mesh is a multifaceted aspect of the purchasing process that demands thorough consideration of several key factors. By understanding how weight, adhesive quality, brand reputation, mesh weave, bulk purchasing opportunities, geographical influences, and compliance certifications affect pricing, consumers can make strategic decisions. These insights not only enhance project outcomes but also ensure long-term satisfaction and value.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories