2 月 . 17, 2025 21:44 Back to list

buy fiberglass mesh tape for drywall

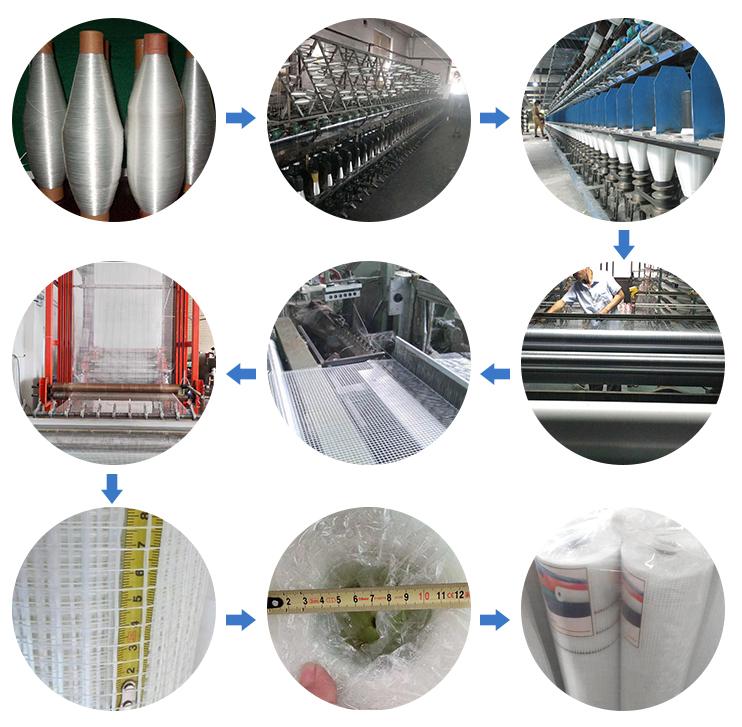

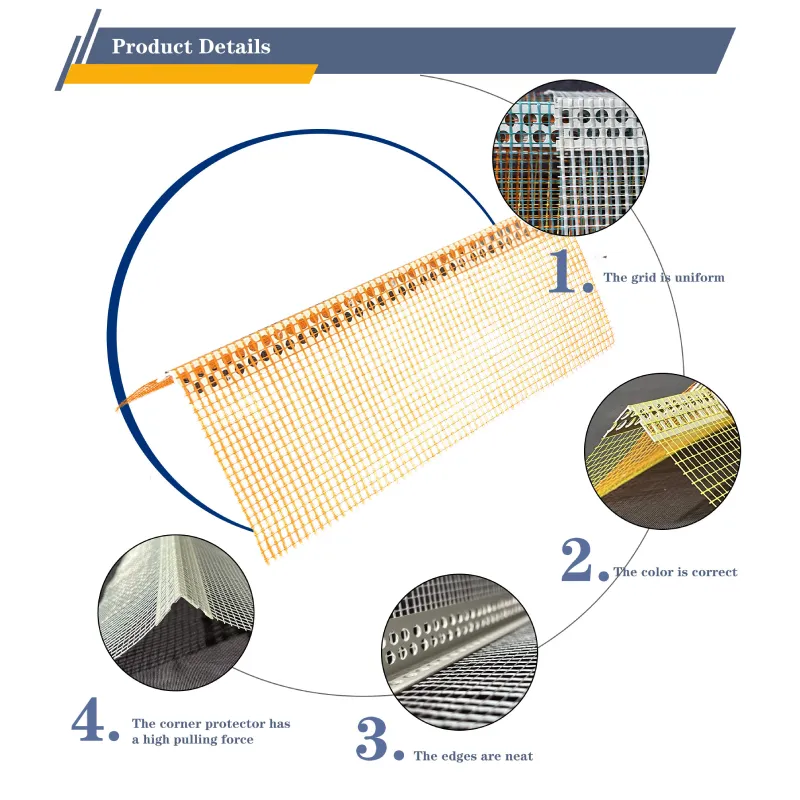

Alkali resistant fiberglass mesh tapes are an essential component in the world of construction and renovation, providing unparalleled strength, durability, and resistance to harsh conditions often encountered on building sites. As the demand for premium quality construction materials grows, many factories worldwide are stepping up to produce top-notch alkali resistant fiberglass mesh tapes. This article explores the intricate process that defines these factories, examining their operational expertise, industry authority, and the trust they garner from global partners.

Trustworthiness is another critical aspect that distinguishes reputable alkali resistant fiberglass mesh tape factories. Transparency in sourcing raw materials, maintaining fair labor practices, and implementing sustainable manufacturing processes are hallmarks of a trustworthy operation. These companies often have robust quality assurance systems in place, with every batch of product undergoing rigorous testing to ensure it meets the highest standards of durability and performance. Additionally, long-standing relationships with construction giants and positive customer testimonials serve as testament to their reliability and commitment to quality. An authentic experience narrative comes alive within these factories, formed from years of dealing with the challenges and triumphs associated with meeting the stringent demands of the construction industry. From engineers fine-tuning production processes to teams overseeing quality control measures, the human element in these factories is what drives innovation and excellence. Employees in these environments often have years of experience, providing invaluable insights that help shape the superior construction solutions we see today. Furthermore, as environmental concerns grow, many factories have adopted sustainable practices, using environmentally friendly binding materials and reducing waste throughout their processes. This not only enhances their trustworthiness but also plays a critical role in preserving natural resources for future generations. In conclusion, alkali resistant fiberglass mesh tape factories are at the forefront of a rapidly evolving construction landscape. By maintaining high standards of expertise, demonstrating industry authority, building trust through transparency, and continually innovating, these factories perform a vital role in providing construction solutions that are robust, reliable, and sustainable. As the industry advances, the importance of these manufacturing powerhouses will undoubtedly continue to grow, meeting the ever-increasing demands for durability and resilience in construction projects worldwide.

Trustworthiness is another critical aspect that distinguishes reputable alkali resistant fiberglass mesh tape factories. Transparency in sourcing raw materials, maintaining fair labor practices, and implementing sustainable manufacturing processes are hallmarks of a trustworthy operation. These companies often have robust quality assurance systems in place, with every batch of product undergoing rigorous testing to ensure it meets the highest standards of durability and performance. Additionally, long-standing relationships with construction giants and positive customer testimonials serve as testament to their reliability and commitment to quality. An authentic experience narrative comes alive within these factories, formed from years of dealing with the challenges and triumphs associated with meeting the stringent demands of the construction industry. From engineers fine-tuning production processes to teams overseeing quality control measures, the human element in these factories is what drives innovation and excellence. Employees in these environments often have years of experience, providing invaluable insights that help shape the superior construction solutions we see today. Furthermore, as environmental concerns grow, many factories have adopted sustainable practices, using environmentally friendly binding materials and reducing waste throughout their processes. This not only enhances their trustworthiness but also plays a critical role in preserving natural resources for future generations. In conclusion, alkali resistant fiberglass mesh tape factories are at the forefront of a rapidly evolving construction landscape. By maintaining high standards of expertise, demonstrating industry authority, building trust through transparency, and continually innovating, these factories perform a vital role in providing construction solutions that are robust, reliable, and sustainable. As the industry advances, the importance of these manufacturing powerhouses will undoubtedly continue to grow, meeting the ever-increasing demands for durability and resilience in construction projects worldwide.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories