1 月 . 19, 2025 04:24 Back to list

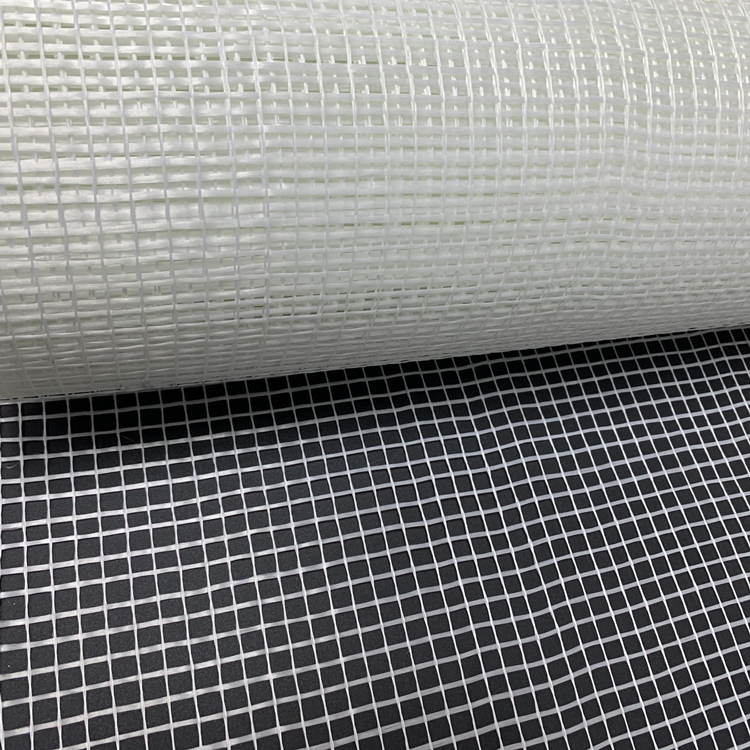

fiberglass mesh netting

Alkali resistant fibreglass mesh, often used in construction and renovation projects, has become a cornerstone for professionals seeking durability and quality. Its unique properties make it indispensable, optimizing its use in various architectural applications. This exploration provides insight into the benefits, real-world applications, and considerations needed when selecting this material, all underpinned by an expertise-driven perspective.

Reliability also springs from compliance with stringent industry standards. Manufacturers of alkali resistant fibreglass mesh adhere to international quality benchmarks. Each roll of mesh is carefully produced to meet rigorous specifications, ensuring uniformity and performance. Such attentiveness to production processes enhances trust among consumers—engineers and builders know that the materials they work with are not only effective but also safe. When procuring this product, decision-makers in construction must consider specific project needs. For example, variations in mesh weight and thickness accommodate different degrees of stress and tensile requirements. Those well-versed in this domain understand that selecting the correct specification of fibreglass mesh can drastically influence project outcomes, from cost-efficiency to durability. Price is another aspect where experience plays a crucial role. While premium grades offer superior durability, cost-conscious professionals weigh this against project budgets and objectives. Experienced buyers often negotiate directly with reputable manufacturers for bulk purchases, securing favorable terms that align with both financial and quality expectations. Moreover, integrating alkali resistant fibreglass mesh within project timelines demands precise coordination. Installation should coincide with particular stages of wall finishes, ensuring the preservation of its structural contributions. Employing skilled labor further amplifies the mesh’s benefits, as correctness in application is as vital as the product itself. In conclusion, the choice and use of alkali resistant fibreglass mesh represent a complex interplay of expertise, reliability, and informed decision-making. Its ability to fortify construction projects speaks volumes of its innovation and design. For professionals, embedding this material into their projects not only heightens performance but also cultivates trust with stakeholders, affirming their commitment to excellence and sustainability in the built environment.

Reliability also springs from compliance with stringent industry standards. Manufacturers of alkali resistant fibreglass mesh adhere to international quality benchmarks. Each roll of mesh is carefully produced to meet rigorous specifications, ensuring uniformity and performance. Such attentiveness to production processes enhances trust among consumers—engineers and builders know that the materials they work with are not only effective but also safe. When procuring this product, decision-makers in construction must consider specific project needs. For example, variations in mesh weight and thickness accommodate different degrees of stress and tensile requirements. Those well-versed in this domain understand that selecting the correct specification of fibreglass mesh can drastically influence project outcomes, from cost-efficiency to durability. Price is another aspect where experience plays a crucial role. While premium grades offer superior durability, cost-conscious professionals weigh this against project budgets and objectives. Experienced buyers often negotiate directly with reputable manufacturers for bulk purchases, securing favorable terms that align with both financial and quality expectations. Moreover, integrating alkali resistant fibreglass mesh within project timelines demands precise coordination. Installation should coincide with particular stages of wall finishes, ensuring the preservation of its structural contributions. Employing skilled labor further amplifies the mesh’s benefits, as correctness in application is as vital as the product itself. In conclusion, the choice and use of alkali resistant fibreglass mesh represent a complex interplay of expertise, reliability, and informed decision-making. Its ability to fortify construction projects speaks volumes of its innovation and design. For professionals, embedding this material into their projects not only heightens performance but also cultivates trust with stakeholders, affirming their commitment to excellence and sustainability in the built environment.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories