12 月 . 05, 2024 18:38 Back to list

China High-Quality Alkali Resistant Fiberglass Mesh for Durable Construction Applications

China's Alkali Resistant Fiberglass Mesh An Overview of Its Applications and Benefits

Alkali resistant fiberglass mesh has become an essential material in the construction and building industry, especially in China, where rapid urbanization and infrastructure development have led to a growing demand for durable and efficient construction solutions. This article aims to explore the properties, applications, and benefits of alkali resistant fiberglass mesh and its significance in modern construction practices.

Understanding Alkali Resistant Fiberglass Mesh

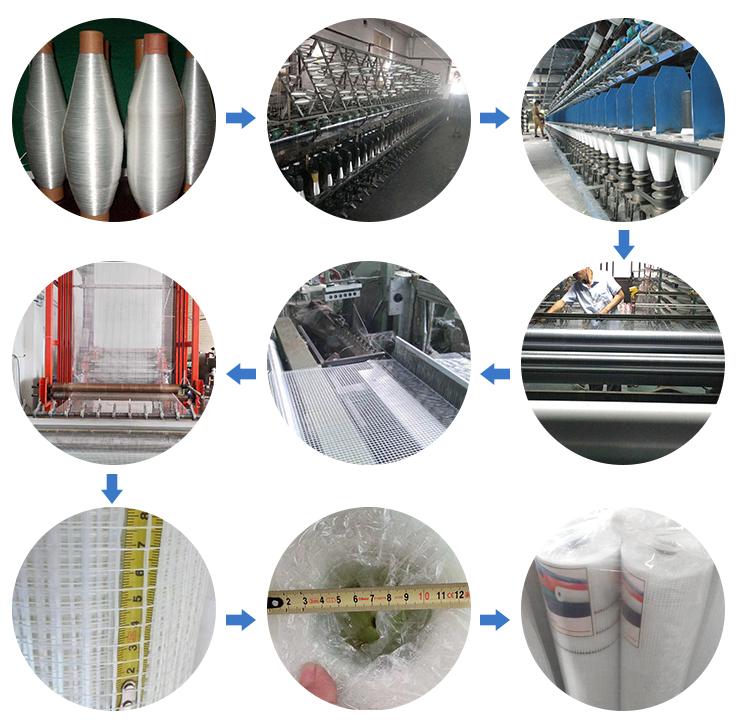

Alkali resistant fiberglass mesh is a type of woven fabric made from fiberglass strands that have been treated to withstand high alkalinity and corrosive substances commonly found in construction materials, such as cement. Its unique composition gives it enhanced durability, flexibility, and resistance to extreme environmental conditions, making it an ideal choice for reinforcing building materials.

Key Properties

1. Alkali Resistance As the name suggests, the primary advantage of this mesh lies in its ability to resist damage from alkaline substances. This property is crucial in cement-based applications where traditional fiberglass meshes would deteriorate over time.

2. High Tensile Strength Alkali resistant fiberglass mesh exhibits superior tensile strength, allowing it to provide excellent reinforcement for various construction materials. This strength is vital for enhancing the structural integrity of buildings, especially in areas prone to seismic activity.

3. Lightweight and Flexible Unlike steel reinforcement bars, fiberglass mesh is lightweight, making it easier to handle and install. Its flexibility allows it to contour to different surfaces, ensuring complete coverage and support.

china alkali resistant fibreglass mesh

4. Corrosion Resistance The non-corrosive nature of fiberglass means that it does not rust or corrode over time, contributing to the longevity of structures. This is particularly significant in coastal areas or regions with high humidity where metal reinforcements may fail.

Applications in Construction

1. External Wall Insulation Systems Alkali resistant fiberglass mesh is predominantly used in External Insulation and Finishing Systems (EIFS). It acts as a reinforcing layer in the insulation boards, improving the overall strength and stability of exterior walls. This application helps to improve energy efficiency in buildings.

2. Plaster Reinforcement In plasterwork, alkali resistant fiberglass mesh is embedded within the plaster layer to prevent cracking and improve the surface finish. This is essential in regions where temperature fluctuations can cause thermal expansion and contraction.

3. Concrete Reinforcement The mesh is widely used in the reinforcement of concrete elements such as slabs, beams, and foundations. By incorporating alkali resistant fiberglass mesh into concrete, builders enhance the tensile strength and durability of the structure.

4. Repair and Renovation For repairing existing structures, alkali resistant fiberglass mesh is often employed in patching and reinforcing applications. It helps in extending the lifespan of buildings, reducing the need for extensive renovations.

Conclusion

China's commitment to improving construction practices is evident through the increasing adoption of advanced materials such as alkali resistant fiberglass mesh. Its unique properties and multiple applications make it an indispensable component in modern construction, offering solutions that enhance durability, strength, and overall performance. As the demand for high-quality construction materials continues to rise, the role of alkali resistant fiberglass mesh in ensuring sustainable and resilient infrastructure will remain paramount. Whether in new developments or renovation projects, this innovative material is set to become a staple in the construction industry, paving the way for more robust and lasting structures.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024