2 月 . 16, 2025 14:03 Back to list

coated fiberglass mesh factories

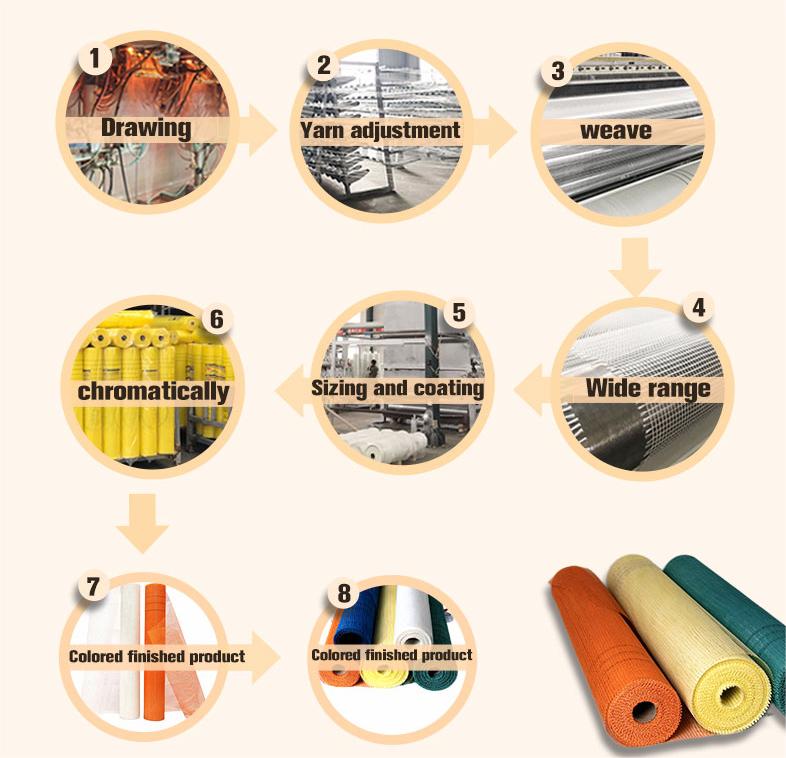

The world of coated fiberglass mesh factories is a dynamic domain that's continuously evolving with advanced technology and innovation. These factories specialize in producing versatile and durable mesh products that are integral to a variety of industries, from construction to automotive. Understanding the intricacies of these manufacturing entities provides deeper insight into their operations and the high-quality products they deliver.

Authoritativeness is crucial in the fiberglass mesh industry, as products are often used in critical applications where safety and reliability are non-negotiable. Leading factories maintain certifications from recognized industry bodies, reflecting their adherence to strict production guidelines and quality assurance protocols. These certifications serve as a testament to their capability and reliability, providing customers with confidence in their products' safety and effectiveness. Trustworthiness extends beyond product quality to encompass business practices. Factories that prioritize transparent operations, fair pricing, and ethical sourcing of materials build lasting relationships with their partners and clients. This trust is further reinforced through excellent customer service, prompt responses to inquiries, and a willingness to stand behind their products with warranties and after-sales support. In a marketplace brimming with competition, coated fiberglass mesh factories that excel in experience, expertise, authoritativeness, and trustworthiness manage to distinguish themselves. They blend traditional manufacturing excellence with forward-thinking approaches, ensuring ongoing relevance and innovation. By prioritizing these four elements, these factories not only thrive in their industry but also contribute positively to the environments they serve. As industries continue to evolve, coated fiberglass mesh will remain a pivotal material, and the factories that manufacture it will play a vital role in shaping future developments. These factories not only supply products but also drive innovation, ensuring their offerings meet ever-changing demands while setting benchmarks for quality and reliability.

Authoritativeness is crucial in the fiberglass mesh industry, as products are often used in critical applications where safety and reliability are non-negotiable. Leading factories maintain certifications from recognized industry bodies, reflecting their adherence to strict production guidelines and quality assurance protocols. These certifications serve as a testament to their capability and reliability, providing customers with confidence in their products' safety and effectiveness. Trustworthiness extends beyond product quality to encompass business practices. Factories that prioritize transparent operations, fair pricing, and ethical sourcing of materials build lasting relationships with their partners and clients. This trust is further reinforced through excellent customer service, prompt responses to inquiries, and a willingness to stand behind their products with warranties and after-sales support. In a marketplace brimming with competition, coated fiberglass mesh factories that excel in experience, expertise, authoritativeness, and trustworthiness manage to distinguish themselves. They blend traditional manufacturing excellence with forward-thinking approaches, ensuring ongoing relevance and innovation. By prioritizing these four elements, these factories not only thrive in their industry but also contribute positively to the environments they serve. As industries continue to evolve, coated fiberglass mesh will remain a pivotal material, and the factories that manufacture it will play a vital role in shaping future developments. These factories not only supply products but also drive innovation, ensuring their offerings meet ever-changing demands while setting benchmarks for quality and reliability.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories