2 月 . 16, 2025 14:57 Back to list

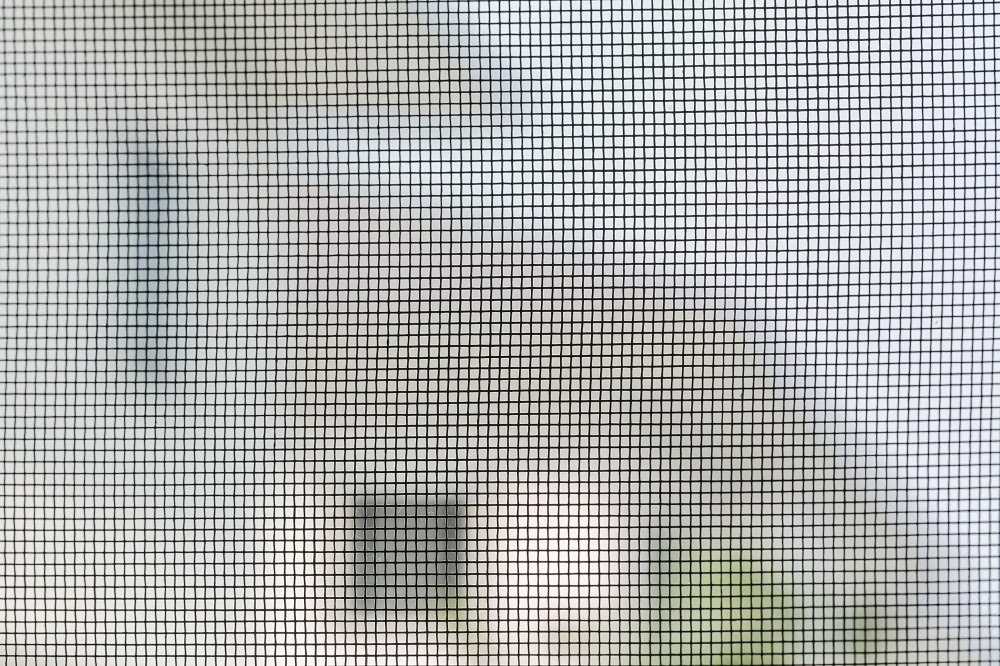

coated fiberglass mesh products

The construction and renovation industries have long sought materials that combine strength, durability, and versatility. Among these, coated fiberglass mesh products have emerged as a modern solution for a variety of applications. Their unique properties offer significant advantages, making them indispensable in projects that range from residential to industrial.

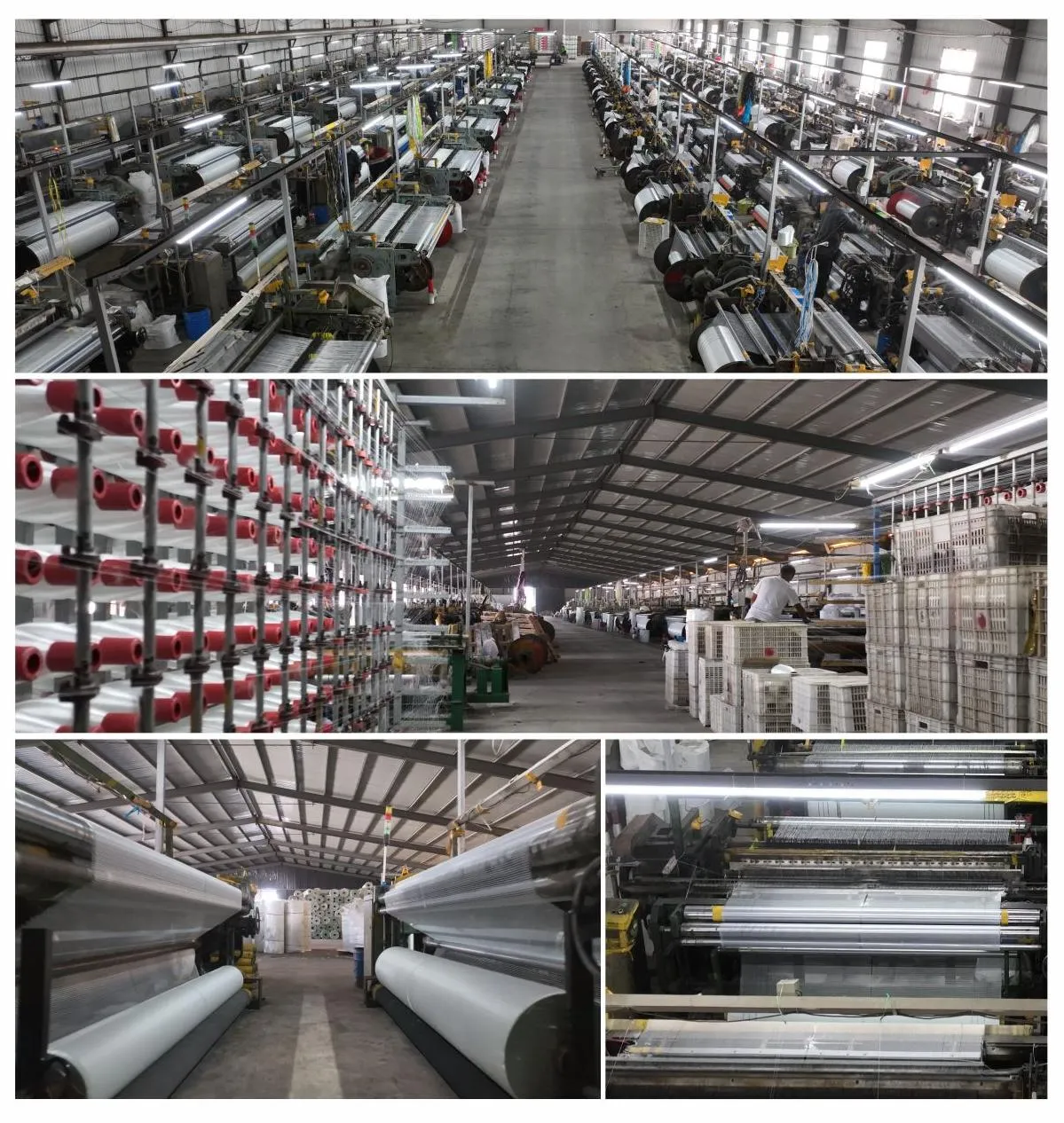

For industry experts, the application of coated fiberglass mesh extends beyond mere reinforcement. It plays a critical role in modern thermal insulation systems. By acting as a stabilizing entity in External Thermal Insulation Composite Systems (ETICS), this mesh helps improve energy efficiency within buildings. As global focus shifts towards sustainability and energy conservation, the use of fiberglass mesh in wall systems becomes a strategic choice, significantly reducing heating and cooling costs. The credibility of coated fiberglass mesh products is supported by extensive testing and certification. Reputable manufacturers ensure their products meet stringent international standards for performance and safety, providing users with added confidence in their investments. The documented success in large-scale infrastructure projects serves as testament to their reliability—a crucial factor for stakeholders involved in the planning and execution of expansive construction endeavors. Furthermore, the market for coated fiberglass mesh is abundant with expert knowledge and technical support, provided by manufacturers and suppliers committed to customer education and satisfaction. This comprehensive support network assists customers in selecting the appropriate product specifications to align with their specific project requirements, fostering an informed decision-making process. The assurance that comes with expert guidance cannot be overstated, as it significantly impacts the quality and outcome of construction projects. In conclusion, the integration of coated fiberglass mesh into building systems is a reflection of evolving industry standards towards more resilient and efficient construction solutions. With its proven track record, versatility, and eco-friendly credentials, it is a material that offers substantial benefits, combining experience, expertise, authoritativeness, and trustworthiness in a package that meets the demands of modern architectural and construction challenges. As such, coated fiberglass mesh products cement their role as vital components for today’s infrastructure needs and future developments.

For industry experts, the application of coated fiberglass mesh extends beyond mere reinforcement. It plays a critical role in modern thermal insulation systems. By acting as a stabilizing entity in External Thermal Insulation Composite Systems (ETICS), this mesh helps improve energy efficiency within buildings. As global focus shifts towards sustainability and energy conservation, the use of fiberglass mesh in wall systems becomes a strategic choice, significantly reducing heating and cooling costs. The credibility of coated fiberglass mesh products is supported by extensive testing and certification. Reputable manufacturers ensure their products meet stringent international standards for performance and safety, providing users with added confidence in their investments. The documented success in large-scale infrastructure projects serves as testament to their reliability—a crucial factor for stakeholders involved in the planning and execution of expansive construction endeavors. Furthermore, the market for coated fiberglass mesh is abundant with expert knowledge and technical support, provided by manufacturers and suppliers committed to customer education and satisfaction. This comprehensive support network assists customers in selecting the appropriate product specifications to align with their specific project requirements, fostering an informed decision-making process. The assurance that comes with expert guidance cannot be overstated, as it significantly impacts the quality and outcome of construction projects. In conclusion, the integration of coated fiberglass mesh into building systems is a reflection of evolving industry standards towards more resilient and efficient construction solutions. With its proven track record, versatility, and eco-friendly credentials, it is a material that offers substantial benefits, combining experience, expertise, authoritativeness, and trustworthiness in a package that meets the demands of modern architectural and construction challenges. As such, coated fiberglass mesh products cement their role as vital components for today’s infrastructure needs and future developments.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories