2 月 . 17, 2025 16:03 Back to list

concrete fiberglass mesh pricelist

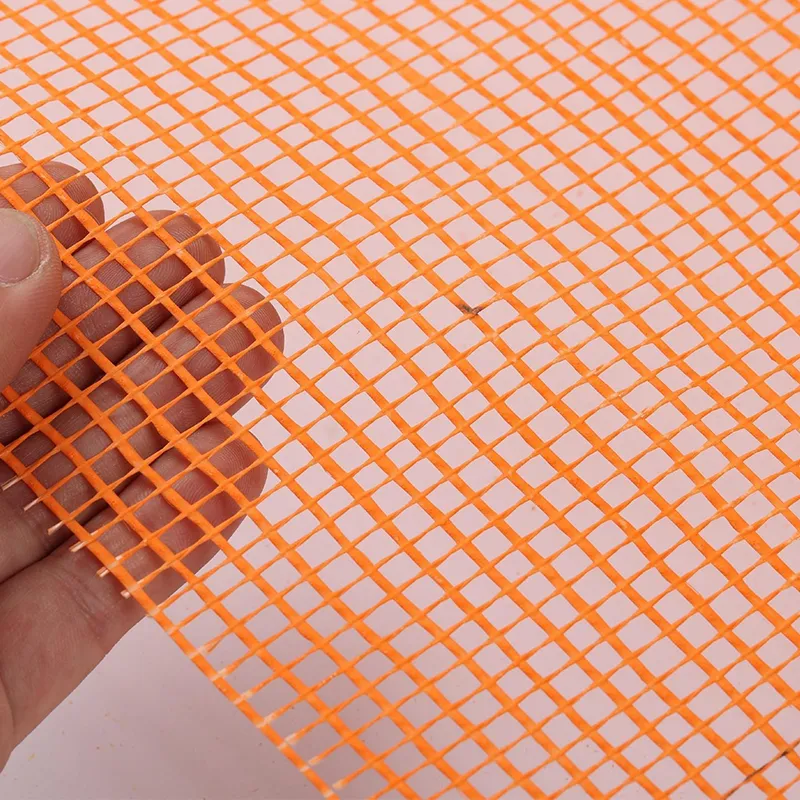

The construction industry is ever-evolving, with materials like concrete fiberglass mesh becoming popular due to their unparalleled advantages. Understanding the pricing of these materials is crucial for project planning and budget allocation. This article delves into the intricacies of concrete fiberglass mesh pricing, drawing from expert knowledge and industry experience to provide authoritative insights that can be trusted.

Geographical location impacts shipping costs and availability, influencing the final price of fiberglass mesh. In regions where production facilities are abundant, such as Southeast Asia, prices may be more competitive due to lower shipping costs. Conversely, in areas where fiberglass mesh is less commonly produced, procurement can be more costly. It is also important to consider the current economic climate. Inflation, fluctuating exchange rates, and changes in raw material costs can affect pricing significantly. In recent times, supply chain disruptions have led to increased costs which are often reflected in pricing. Staying updated with market trends is vital for consumers and industry professionals, ensuring they make informed purchasing decisions. When choosing concrete fiberglass mesh, it is essential to prioritize quality and suitability for the specific project needs over mere cost. While cheaper options may seem appealing, they often come at the expense of performance and durability. Consulting with industry experts and suppliers can provide deeper insights and lead to cost-effective solutions that do not compromise on quality. For those considering bulk purchases, engaging with manufacturers for price lists and potential discounts could lead to significant savings. Many suppliers offer scale-based pricing, where discounts are provided based on the volume of purchase. Establishing solid relationships with vendors also paves the way for better negotiation power and access to premium products at competitive prices. In summary, while the price list of concrete fiberglass mesh is influenced by multiple factors, making informed choices based on thorough research and expert consultation can optimize both cost and performance. This foresight ensures the longevity and integrity of construction projects, a testament to the invaluable experience and expertise that guides every purchase decision in this sector.

Geographical location impacts shipping costs and availability, influencing the final price of fiberglass mesh. In regions where production facilities are abundant, such as Southeast Asia, prices may be more competitive due to lower shipping costs. Conversely, in areas where fiberglass mesh is less commonly produced, procurement can be more costly. It is also important to consider the current economic climate. Inflation, fluctuating exchange rates, and changes in raw material costs can affect pricing significantly. In recent times, supply chain disruptions have led to increased costs which are often reflected in pricing. Staying updated with market trends is vital for consumers and industry professionals, ensuring they make informed purchasing decisions. When choosing concrete fiberglass mesh, it is essential to prioritize quality and suitability for the specific project needs over mere cost. While cheaper options may seem appealing, they often come at the expense of performance and durability. Consulting with industry experts and suppliers can provide deeper insights and lead to cost-effective solutions that do not compromise on quality. For those considering bulk purchases, engaging with manufacturers for price lists and potential discounts could lead to significant savings. Many suppliers offer scale-based pricing, where discounts are provided based on the volume of purchase. Establishing solid relationships with vendors also paves the way for better negotiation power and access to premium products at competitive prices. In summary, while the price list of concrete fiberglass mesh is influenced by multiple factors, making informed choices based on thorough research and expert consultation can optimize both cost and performance. This foresight ensures the longevity and integrity of construction projects, a testament to the invaluable experience and expertise that guides every purchase decision in this sector.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories