6 月 . 17, 2024 14:50 Back to list

Drywall fiberglass tape products are essential for wall repairs.

The Versatile World of Drywall Fiberglass Tape Products

In the realm of construction and home improvement, drywall fiberglass tape products have become an indispensable tool for achieving a seamless finish. These tapes are not mere accessories; they're critical components that ensure the integrity and aesthetic appeal of walls and ceilings. Let’s delve into the world of these remarkable products and explore their significance.

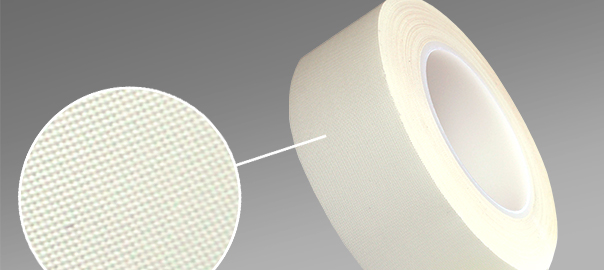

Drywall fiberglass tape, also known as joint tape, is made from fiberglass strands woven into a paper or mesh backing. This combination offers strength, flexibility, and resistance to cracking. When combined with joint compound, it creates a robust foundation for covering seams between drywall panels. It effectively prevents the penetration of moisture and mold, making it ideal for various environments, including bathrooms and basements.

The process of applying drywall fiberglass tape is both an art and a science. First, the seams between drywall sheets must be filled with a layer of joint compound. Then, the tape is pressed into the wet compound, ensuring full embedding. After the compound dries, one or more additional coats are applied to smooth out the surface and blend it with the surrounding area. Upon drying, the result is a monolithic surface ready for painting or finishing.

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions drywall fiberglass tape products. Paper tape can buckle or fail when exposed to moisture, whereas fiberglass tape maintains its integrity. Moreover, fiberglass tapes often have a grid-like pattern on the backside that improves adhesion with the joint compound, further enhancing durability.

In the market, there are various types of drywall fiberglass tapes designed for specific applications. For instance, some tapes are specially treated to resist mold and mildew, making them perfect for areas prone to high humidity. Others may be thinner or thicker depending on the width of the seams they are intended to cover.

Beyond functionality, drywall fiberglass tape products have evolved to cater to different installation techniques and personal preferences. Pre-mixed compounds with tape already embedded offer a quicker solution for DIYers looking to simplify the process. On the other hand, professional contractors might prefer traditional tapes that allow for more customized application methods.

In conclusion, drywall fiberglass tape products are essential tools in the construction industry due to their reliability, ease of use, and adaptability to various environments. From new constructions to renovation projects, these tapes play a crucial role in achieving a polished finish that can last for years. As technology continues to advance, we can expect further innovations in this segment, leading to even more efficient and effective solutions for wall finishing needs.

drywall fiberglass tape products. Paper tape can buckle or fail when exposed to moisture, whereas fiberglass tape maintains its integrity. Moreover, fiberglass tapes often have a grid-like pattern on the backside that improves adhesion with the joint compound, further enhancing durability.

In the market, there are various types of drywall fiberglass tapes designed for specific applications. For instance, some tapes are specially treated to resist mold and mildew, making them perfect for areas prone to high humidity. Others may be thinner or thicker depending on the width of the seams they are intended to cover.

Beyond functionality, drywall fiberglass tape products have evolved to cater to different installation techniques and personal preferences. Pre-mixed compounds with tape already embedded offer a quicker solution for DIYers looking to simplify the process. On the other hand, professional contractors might prefer traditional tapes that allow for more customized application methods.

In conclusion, drywall fiberglass tape products are essential tools in the construction industry due to their reliability, ease of use, and adaptability to various environments. From new constructions to renovation projects, these tapes play a crucial role in achieving a polished finish that can last for years. As technology continues to advance, we can expect further innovations in this segment, leading to even more efficient and effective solutions for wall finishing needs.

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions

One of the advantages of using fiberglass tape over traditional paper tape is its superior performance in humid conditions drywall fiberglass tape products. Paper tape can buckle or fail when exposed to moisture, whereas fiberglass tape maintains its integrity. Moreover, fiberglass tapes often have a grid-like pattern on the backside that improves adhesion with the joint compound, further enhancing durability.

In the market, there are various types of drywall fiberglass tapes designed for specific applications. For instance, some tapes are specially treated to resist mold and mildew, making them perfect for areas prone to high humidity. Others may be thinner or thicker depending on the width of the seams they are intended to cover.

Beyond functionality, drywall fiberglass tape products have evolved to cater to different installation techniques and personal preferences. Pre-mixed compounds with tape already embedded offer a quicker solution for DIYers looking to simplify the process. On the other hand, professional contractors might prefer traditional tapes that allow for more customized application methods.

In conclusion, drywall fiberglass tape products are essential tools in the construction industry due to their reliability, ease of use, and adaptability to various environments. From new constructions to renovation projects, these tapes play a crucial role in achieving a polished finish that can last for years. As technology continues to advance, we can expect further innovations in this segment, leading to even more efficient and effective solutions for wall finishing needs.

drywall fiberglass tape products. Paper tape can buckle or fail when exposed to moisture, whereas fiberglass tape maintains its integrity. Moreover, fiberglass tapes often have a grid-like pattern on the backside that improves adhesion with the joint compound, further enhancing durability.

In the market, there are various types of drywall fiberglass tapes designed for specific applications. For instance, some tapes are specially treated to resist mold and mildew, making them perfect for areas prone to high humidity. Others may be thinner or thicker depending on the width of the seams they are intended to cover.

Beyond functionality, drywall fiberglass tape products have evolved to cater to different installation techniques and personal preferences. Pre-mixed compounds with tape already embedded offer a quicker solution for DIYers looking to simplify the process. On the other hand, professional contractors might prefer traditional tapes that allow for more customized application methods.

In conclusion, drywall fiberglass tape products are essential tools in the construction industry due to their reliability, ease of use, and adaptability to various environments. From new constructions to renovation projects, these tapes play a crucial role in achieving a polished finish that can last for years. As technology continues to advance, we can expect further innovations in this segment, leading to even more efficient and effective solutions for wall finishing needs. Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories