2 月 . 15, 2025 06:40 Back to list

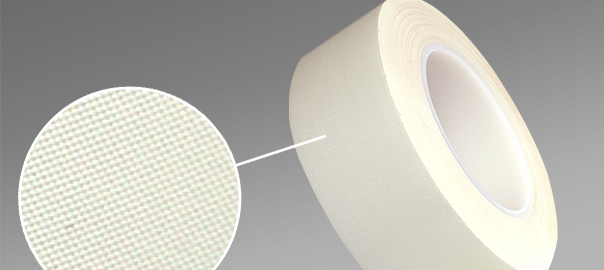

fiberglass wall mesh

In the realm of construction and home renovation, drywall fiberglass mesh products have become indispensable tools, offering unparalleled solutions to both professionals and DIY enthusiasts. Their applications span across various aspects of construction, from securing stability to refining aesthetics. A deep dive into the benefits and versatility of drywall fiberglass mesh reveals why it's a superior choice in the industry.

Furthermore, the lightweight nature of fiberglass mesh contributes to its ease of handling and flexibility during use. This adaptability is particularly beneficial when working with irregular surfaces or corners, where precision is vital. Contractors and homeowners alike will appreciate the ability to contour the mesh to fit unique angles and shapes, ensuring a seamless finish that meets aesthetic and functional standards. In terms of safety, drywall fiberglass mesh is a non-combustible material, adding an element of fire resistance to the structures it fortifies. This aspect significantly enhances the safety profile of buildings, a paramount concern for both residential and commercial properties. The incorporation of such safety features demonstrates a commitment to building resilient and secure environments for occupants. Expert recommendations emphasize the importance of selecting the right mesh thickness and weave to match the specific requirements of each project. Depending on the job at hand, contractors might opt for a finer weave for delicate repairs or a heavier mesh for more extensive reinforcement tasks. This customization ensures that the solution is perfectly tailored to the task, offering both performance and cost-effectiveness. In conclusion, drywall fiberglass mesh products represent a fusion of strength, versatility, and safety, making them an essential component in modern construction and renovation projects. Their ability to enhance the durability of drywall installations while offering added benefits such as moisture and fire resistance positions them as a preferred choice for professionals. By investing in high-quality drywall fiberglass mesh, contractors can assure clients of long-lasting results that stand the test of time, ultimately reflecting the reliability and expertise expected in today’s competitive construction landscape.

Furthermore, the lightweight nature of fiberglass mesh contributes to its ease of handling and flexibility during use. This adaptability is particularly beneficial when working with irregular surfaces or corners, where precision is vital. Contractors and homeowners alike will appreciate the ability to contour the mesh to fit unique angles and shapes, ensuring a seamless finish that meets aesthetic and functional standards. In terms of safety, drywall fiberglass mesh is a non-combustible material, adding an element of fire resistance to the structures it fortifies. This aspect significantly enhances the safety profile of buildings, a paramount concern for both residential and commercial properties. The incorporation of such safety features demonstrates a commitment to building resilient and secure environments for occupants. Expert recommendations emphasize the importance of selecting the right mesh thickness and weave to match the specific requirements of each project. Depending on the job at hand, contractors might opt for a finer weave for delicate repairs or a heavier mesh for more extensive reinforcement tasks. This customization ensures that the solution is perfectly tailored to the task, offering both performance and cost-effectiveness. In conclusion, drywall fiberglass mesh products represent a fusion of strength, versatility, and safety, making them an essential component in modern construction and renovation projects. Their ability to enhance the durability of drywall installations while offering added benefits such as moisture and fire resistance positions them as a preferred choice for professionals. By investing in high-quality drywall fiberglass mesh, contractors can assure clients of long-lasting results that stand the test of time, ultimately reflecting the reliability and expertise expected in today’s competitive construction landscape.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories