2 月 . 17, 2025 14:28 Back to list

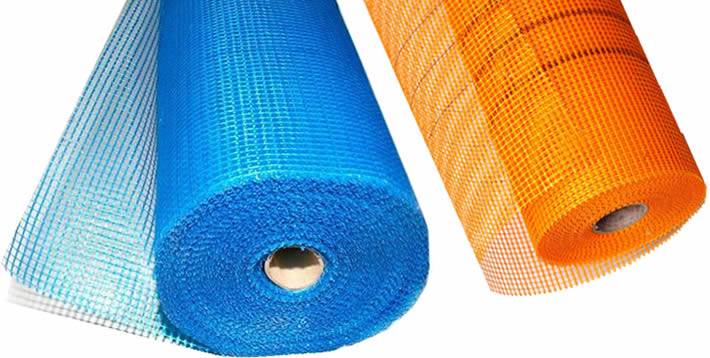

fiberglass wall mesh

In the realm of home improvement and construction, drywall fiberglass tape is an essential tool for seam reinforcement and crack prevention. Understanding how to choose the right drywall fiberglass tape can mean the difference between a professional-looking wall and ongoing repair issues. Customers and contractors alike are eager to source quality products at competitive prices, making it vital to have a comprehensive understanding of the drywall fiberglass tape market.

Case studies from past projects where specific brands or types of fiberglass tape have been used provide valuable knowledge on their efficacy in real-world scenarios. Clients benefit from hearing about successes and pitfalls encountered on similar projects, which in turn builds confidence in recommended products and services. Trustworthiness Through Certifications and Standards Trustworthiness in the drywall fiberglass tape market is bolstered by adherence to industry standards and certifications. Customers are assured of quality through recognitions such as ASTM standards, which confirm the tape's resistance to impact and consistency in performance. Furthermore, suppliers who carry environmentally friendly certifications cater to an ever-increasing demand for sustainable building practices. A transparent supply chain, clear information on product origins, and commitment to eco-friendly standards enhance customer confidence. Innovations and Trends One notable trend is the integration of antimicrobial agents into fiberglass tapes, addressing concerns about mold and mildew, especially in high-humidity areas. Manufacturers are also exploring the use of recycled materials without compromising strength, catering to eco-conscious consumers. Such innovations require suppliers to stay updated and forward-thinking, ensuring they're offering the latest and most effective products on the market. Supplier and Contractor Relationships A strong supplier-contractor relationship is a two-way street that relies on regular communication, feedback, and support. Suppliers who understand the challenges contractors face can more effectively provide the solutions needed, while contractors who maintain open lines of communication with their suppliers are better positioned to negotiate favorable pricing and terms. Conclusion Navigating the complex world of drywall fiberglass tape requires a comprehensive understanding of product types, quality indicators, market trends, and supplier relationships. Businesses that prioritize these factors while maintaining transparent pricing structures will naturally build a reputation for reliability and authority. By continually applying real-world feedback and innovations, drywall professionals can ensure they not only meet, but exceed client expectations, thus cementing their role as trusted experts in the industry.

Case studies from past projects where specific brands or types of fiberglass tape have been used provide valuable knowledge on their efficacy in real-world scenarios. Clients benefit from hearing about successes and pitfalls encountered on similar projects, which in turn builds confidence in recommended products and services. Trustworthiness Through Certifications and Standards Trustworthiness in the drywall fiberglass tape market is bolstered by adherence to industry standards and certifications. Customers are assured of quality through recognitions such as ASTM standards, which confirm the tape's resistance to impact and consistency in performance. Furthermore, suppliers who carry environmentally friendly certifications cater to an ever-increasing demand for sustainable building practices. A transparent supply chain, clear information on product origins, and commitment to eco-friendly standards enhance customer confidence. Innovations and Trends One notable trend is the integration of antimicrobial agents into fiberglass tapes, addressing concerns about mold and mildew, especially in high-humidity areas. Manufacturers are also exploring the use of recycled materials without compromising strength, catering to eco-conscious consumers. Such innovations require suppliers to stay updated and forward-thinking, ensuring they're offering the latest and most effective products on the market. Supplier and Contractor Relationships A strong supplier-contractor relationship is a two-way street that relies on regular communication, feedback, and support. Suppliers who understand the challenges contractors face can more effectively provide the solutions needed, while contractors who maintain open lines of communication with their suppliers are better positioned to negotiate favorable pricing and terms. Conclusion Navigating the complex world of drywall fiberglass tape requires a comprehensive understanding of product types, quality indicators, market trends, and supplier relationships. Businesses that prioritize these factors while maintaining transparent pricing structures will naturally build a reputation for reliability and authority. By continually applying real-world feedback and innovations, drywall professionals can ensure they not only meet, but exceed client expectations, thus cementing their role as trusted experts in the industry.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories