6 月 . 14, 2024 04:30 Back to list

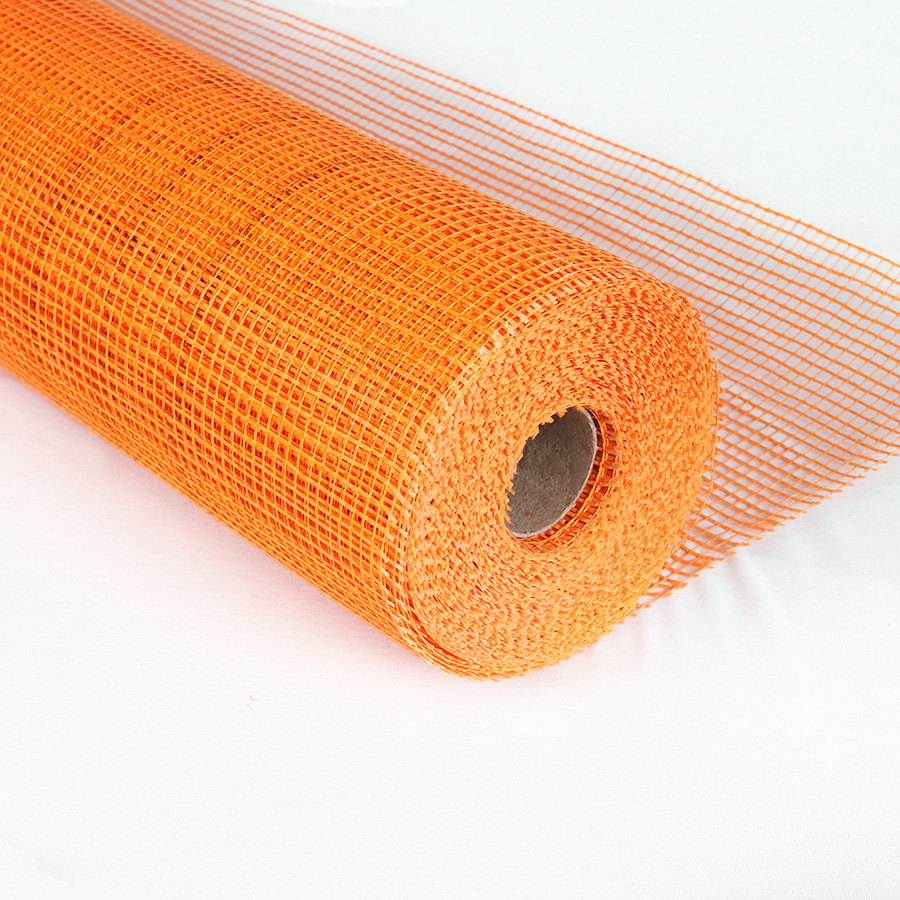

E-glass fiber yarn can be briefly referred to as fiberglass yarn.

The Pivotal Role of E-Glass Fiber Yarn in Modern Industry

E-glass fiber yarn, a product of advanced technology and innovative engineering, has revolutionized the realm of composite materials in recent decades. This specialized form of glass fiber, characterized by its 'E' for electrical neutrality, is a key component in various industries due to its unique properties and versatility.

E-glass fiber yarn is primarily composed of silica, with other minerals added to enhance its electrical insulation and mechanical strength. Its name stems from its primary application - it exhibits exceptional electrical resistance, making it ideal for use in electronics and electrical insulation. However, its utility extends far beyond this domain.

In the construction industry, e-glass fiber yarn is widely used as a reinforcement material in concrete and mortar, increasing durability and reducing crack formation. It forms an integral part of fiber-reinforced polymer (FRP) composites, which are used in bridges, buildings, and other infrastructure projects due to their high strength-to-weight ratio.

The automotive sector also heavily relies on e-glass fiber yarn. Lightweight yet strong, it is incorporated into car bodies and components, contributing to fuel efficiency and overall performance. Similarly, in aerospace, e-glass fibers are used in the manufacture of aircraft parts, offering weight reduction without compromising structural integrity.

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance e glass fiber yarn. In the wind energy industry, it is used in wind turbine blades, enhancing their resistance to extreme weather conditions.

The marine industry too has benefited from e-glass fiber yarn. Its resistance to corrosion and water absorption makes it perfect for boat hulls and other maritime structures. Furthermore, in the field of electronics, it serves as a critical element in printed circuit boards, providing insulation and stability.

Despite its numerous applications, the production and disposal of e-glass fiber yarn raise environmental concerns. Continuous research is being conducted to develop sustainable manufacturing processes and recycling solutions, ensuring its benefits can be harnessed while minimizing ecological impact.

In conclusion, e-glass fiber yarn is more than just a material; it is a technological enabler, transforming industries and driving innovation. Its ability to combine strength, electrical insulation, and versatility makes it a go-to choice for engineers worldwide. As technology continues to advance, the role of e-glass fiber yarn is likely to grow even more prominent, shaping the future of various sectors and our daily lives.

e glass fiber yarn. In the wind energy industry, it is used in wind turbine blades, enhancing their resistance to extreme weather conditions.

The marine industry too has benefited from e-glass fiber yarn. Its resistance to corrosion and water absorption makes it perfect for boat hulls and other maritime structures. Furthermore, in the field of electronics, it serves as a critical element in printed circuit boards, providing insulation and stability.

Despite its numerous applications, the production and disposal of e-glass fiber yarn raise environmental concerns. Continuous research is being conducted to develop sustainable manufacturing processes and recycling solutions, ensuring its benefits can be harnessed while minimizing ecological impact.

In conclusion, e-glass fiber yarn is more than just a material; it is a technological enabler, transforming industries and driving innovation. Its ability to combine strength, electrical insulation, and versatility makes it a go-to choice for engineers worldwide. As technology continues to advance, the role of e-glass fiber yarn is likely to grow even more prominent, shaping the future of various sectors and our daily lives.

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance

Moreover, e-glass fiber yarn finds application in the manufacturing of sporting goods, such as tennis rackets and golf clubs, where its stiffness and strength improve the equipment's performance e glass fiber yarn. In the wind energy industry, it is used in wind turbine blades, enhancing their resistance to extreme weather conditions.

The marine industry too has benefited from e-glass fiber yarn. Its resistance to corrosion and water absorption makes it perfect for boat hulls and other maritime structures. Furthermore, in the field of electronics, it serves as a critical element in printed circuit boards, providing insulation and stability.

Despite its numerous applications, the production and disposal of e-glass fiber yarn raise environmental concerns. Continuous research is being conducted to develop sustainable manufacturing processes and recycling solutions, ensuring its benefits can be harnessed while minimizing ecological impact.

In conclusion, e-glass fiber yarn is more than just a material; it is a technological enabler, transforming industries and driving innovation. Its ability to combine strength, electrical insulation, and versatility makes it a go-to choice for engineers worldwide. As technology continues to advance, the role of e-glass fiber yarn is likely to grow even more prominent, shaping the future of various sectors and our daily lives.

e glass fiber yarn. In the wind energy industry, it is used in wind turbine blades, enhancing their resistance to extreme weather conditions.

The marine industry too has benefited from e-glass fiber yarn. Its resistance to corrosion and water absorption makes it perfect for boat hulls and other maritime structures. Furthermore, in the field of electronics, it serves as a critical element in printed circuit boards, providing insulation and stability.

Despite its numerous applications, the production and disposal of e-glass fiber yarn raise environmental concerns. Continuous research is being conducted to develop sustainable manufacturing processes and recycling solutions, ensuring its benefits can be harnessed while minimizing ecological impact.

In conclusion, e-glass fiber yarn is more than just a material; it is a technological enabler, transforming industries and driving innovation. Its ability to combine strength, electrical insulation, and versatility makes it a go-to choice for engineers worldwide. As technology continues to advance, the role of e-glass fiber yarn is likely to grow even more prominent, shaping the future of various sectors and our daily lives. Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories