2 月 . 15, 2025 16:32 Back to list

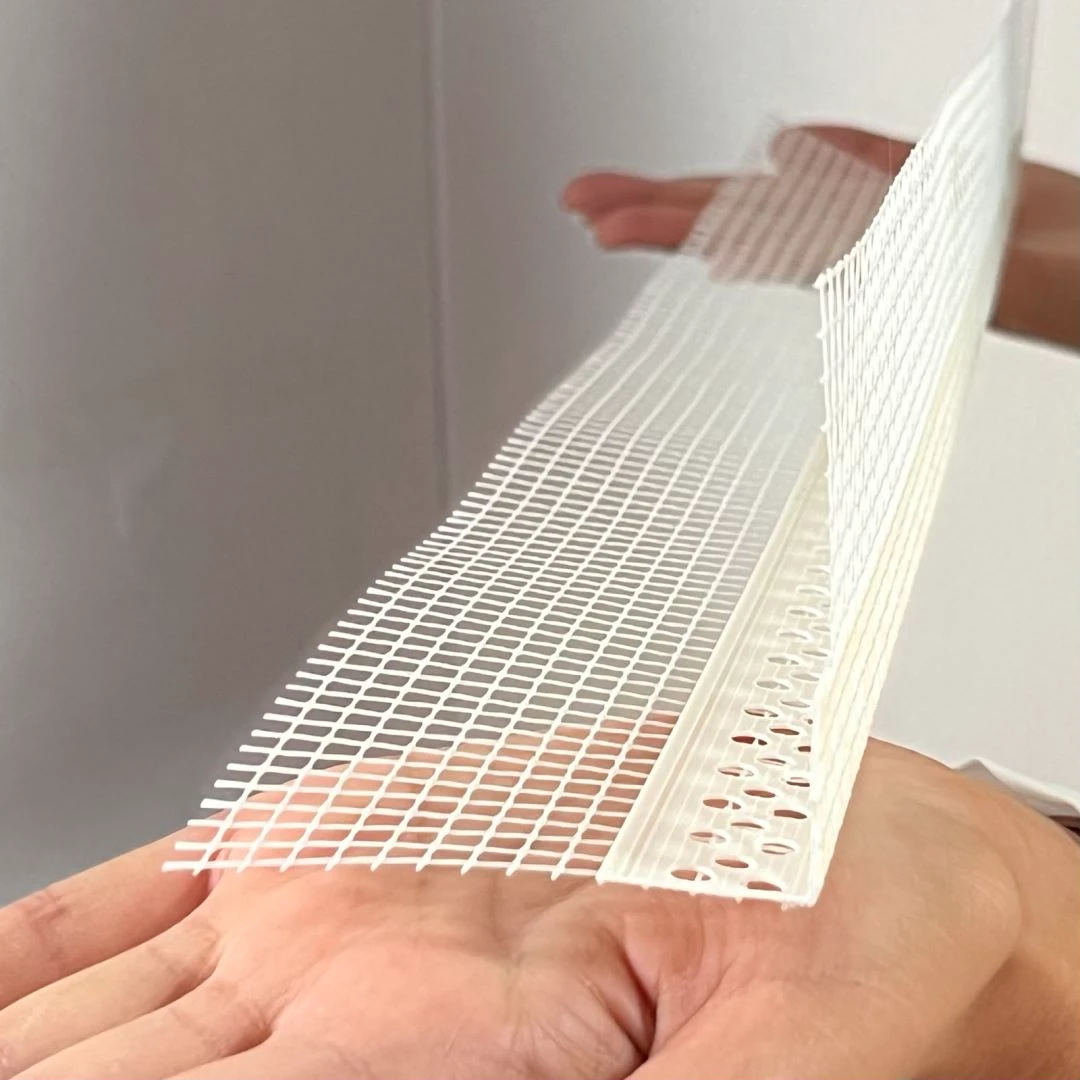

4x4 145g fiberglass mesh roll for Turkey

In the world of construction and home improvement, fiberglass mesh rolls have emerged as a game-changing product. These rolls, produced by specialized factories, play an essential role in reinforcing surfaces and preventing cracks. With a growing emphasis on sustainability and durability, choosing the right fiberglass mesh roll factory is paramount for ensuring quality and efficiencies in various applications.

Given the crucial role that these factories play, trustworthiness becomes a significant part of the decision-making process. Trust is built through a transparent supply chain, which includes everything from sourcing raw materials to delivering the finished product. Leading factories are often transparent about their sourcing, ensuring that the fiberglass used is of the highest quality and ethically sourced. Additionally, they maintain open channels of communication with clients, offering comprehensive support and guidance throughout the purchasing process and beyond. Notably, these factories often showcase case studies and testimonials from previous projects, which serve as practical demonstrations of their products' effectiveness. Whether it's reinforcing high-rise buildings or being used in home renovations, these success stories highlight the versatility and dependability of their fiberglass mesh rolls. In terms of experience, the longevity of a factory in the market often speaks volumes about its credibility. Factories that have been operational for numerous years have navigated different industry trends, economic climates, and technological evolutions. Their sustained presence is usually indicative of their ability to adapt and stay relevant, continuing to meet market demands while maintaining product excellence. Lastly, embracing sustainability isn't just a trend but a responsibility. Responsible fiberglass mesh roll factories are now looking towards eco-friendly practices, ensuring their processes reduce environmental impact. This involves reducing waste, utilizing energy-efficient machinery, and exploring biodegradable coating materials. By aligning with such factories, customers are not only purchasing a product but are also contributing to a more sustainable future. In conclusion, selecting the right fiberglass mesh roll factory involves considering their experience, expertise, authority within the industry, and trustworthiness. As construction standards continue to evolve, partnering with a factory that embodies these qualities ensures that the projects not only meet current requirements but are also future-proofed against upcoming challenges and standards. The right manufacturer isn't just a supplier but a partner in innovation and quality assurance.

Given the crucial role that these factories play, trustworthiness becomes a significant part of the decision-making process. Trust is built through a transparent supply chain, which includes everything from sourcing raw materials to delivering the finished product. Leading factories are often transparent about their sourcing, ensuring that the fiberglass used is of the highest quality and ethically sourced. Additionally, they maintain open channels of communication with clients, offering comprehensive support and guidance throughout the purchasing process and beyond. Notably, these factories often showcase case studies and testimonials from previous projects, which serve as practical demonstrations of their products' effectiveness. Whether it's reinforcing high-rise buildings or being used in home renovations, these success stories highlight the versatility and dependability of their fiberglass mesh rolls. In terms of experience, the longevity of a factory in the market often speaks volumes about its credibility. Factories that have been operational for numerous years have navigated different industry trends, economic climates, and technological evolutions. Their sustained presence is usually indicative of their ability to adapt and stay relevant, continuing to meet market demands while maintaining product excellence. Lastly, embracing sustainability isn't just a trend but a responsibility. Responsible fiberglass mesh roll factories are now looking towards eco-friendly practices, ensuring their processes reduce environmental impact. This involves reducing waste, utilizing energy-efficient machinery, and exploring biodegradable coating materials. By aligning with such factories, customers are not only purchasing a product but are also contributing to a more sustainable future. In conclusion, selecting the right fiberglass mesh roll factory involves considering their experience, expertise, authority within the industry, and trustworthiness. As construction standards continue to evolve, partnering with a factory that embodies these qualities ensures that the projects not only meet current requirements but are also future-proofed against upcoming challenges and standards. The right manufacturer isn't just a supplier but a partner in innovation and quality assurance.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories