2 月 . 11, 2025 16:16 Back to list

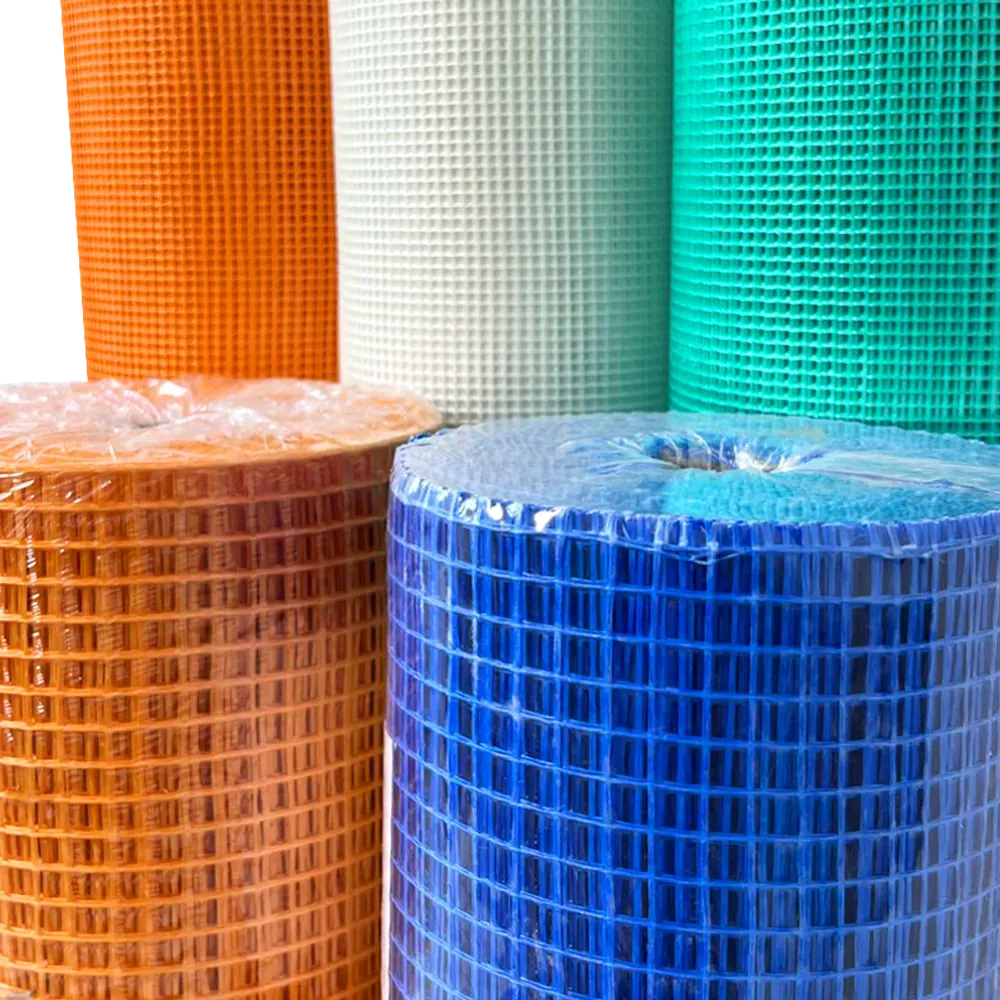

fiberglass eifs mesh manufacturer

In the vast world of construction materials, fiberglass EIFS mesh stands out as a cornerstone of modern building innovations. With the increase in demand for energy-efficient and durable building systems, manufacturers specializing in fiberglass EIFS mesh play an integral role in shaping the future of architectural design.

Trustworthiness is a key attribute of top-tier fiberglass EIFS mesh manufacturers. They prioritize quality assurance, ensuring that their products meet international safety and sustainability standards. Through certifications and quality control audits, manufacturers build trust with stakeholders — from designers to end-users. Ensuring the consistent quality of fiberglass EIFS mesh is fundamental to building and maintaining this trust. A cutting-edge approach from manufacturers includes the use of environmental friendly practices. Incorporating recycled materials into the production process minimizes waste, aligning with global sustainability trends. By committing to eco-friendly initiatives, these manufacturers not only contribute positively to the environment but also appeal to an increasingly environmentally conscious market. Innovation is at the heart of the industry's evolution. Leading manufacturers invest heavily in technological advancements, such as enhancing the thermal performance of the mesh. By improving the insulative properties of the EIFS systems, they help decrease heating and cooling costs for buildings, making them attractive to both property developers and owners looking to reduce energy expenses. Another noteworthy innovation is the integration of smart technology. Some manufacturers are exploring smart mesh systems capable of monitoring structural integrity in real time. These meshes can provide critical data about stress levels and potential vulnerabilities, enabling preemptive maintenance and ensuring the long-term durability of the building structures. In summary, the role of fiberglass EIFS mesh manufacturers extends beyond just producing a building material. They are crucial players in the drive toward more energy-efficient, sustainable, and intelligent buildings. Their expertise, authority, and commitment to quality not only support the construction industry but also advance it, making the built environment more resilient and adaptable to future challenges.

Trustworthiness is a key attribute of top-tier fiberglass EIFS mesh manufacturers. They prioritize quality assurance, ensuring that their products meet international safety and sustainability standards. Through certifications and quality control audits, manufacturers build trust with stakeholders — from designers to end-users. Ensuring the consistent quality of fiberglass EIFS mesh is fundamental to building and maintaining this trust. A cutting-edge approach from manufacturers includes the use of environmental friendly practices. Incorporating recycled materials into the production process minimizes waste, aligning with global sustainability trends. By committing to eco-friendly initiatives, these manufacturers not only contribute positively to the environment but also appeal to an increasingly environmentally conscious market. Innovation is at the heart of the industry's evolution. Leading manufacturers invest heavily in technological advancements, such as enhancing the thermal performance of the mesh. By improving the insulative properties of the EIFS systems, they help decrease heating and cooling costs for buildings, making them attractive to both property developers and owners looking to reduce energy expenses. Another noteworthy innovation is the integration of smart technology. Some manufacturers are exploring smart mesh systems capable of monitoring structural integrity in real time. These meshes can provide critical data about stress levels and potential vulnerabilities, enabling preemptive maintenance and ensuring the long-term durability of the building structures. In summary, the role of fiberglass EIFS mesh manufacturers extends beyond just producing a building material. They are crucial players in the drive toward more energy-efficient, sustainable, and intelligent buildings. Their expertise, authority, and commitment to quality not only support the construction industry but also advance it, making the built environment more resilient and adaptable to future challenges.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories