2 月 . 04, 2025 05:59 Back to list

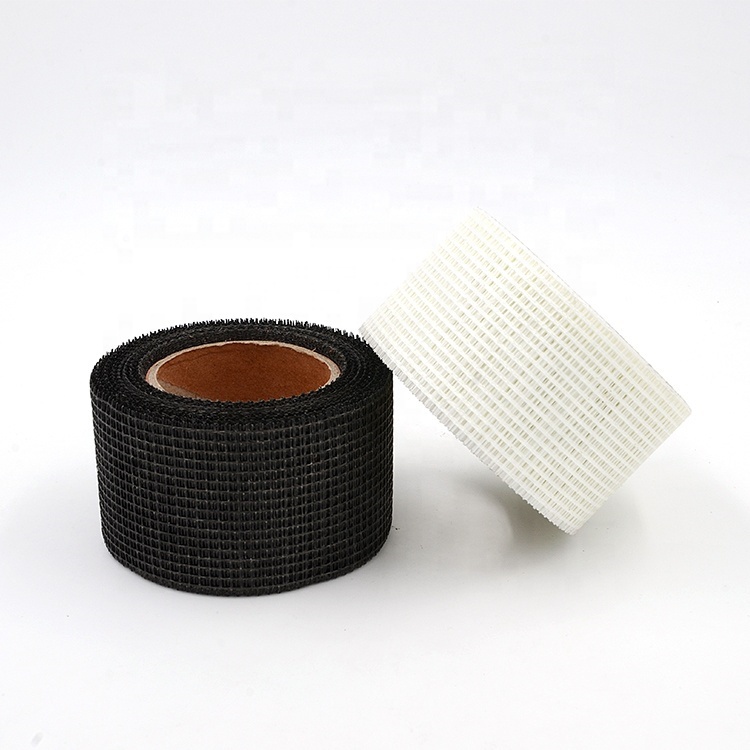

4x4 145g fiberglass mesh roll for Turkey

Fiberglass insulation mesh is an increasingly favored product in the construction and manufacturing industries due to its versatility and durability. As a specialist in fiberglass insulation mesh production, the factors driving a successful factory are rooted in extensive experience, detailed expertise, authoritative processes, and unwavering trustworthiness.

Establishing authority in the fiberglass insulation mesh niche requires more than just expertise and experience—it demands leadership in thought and practice. Factories with a strong presence often contribute to industry standards by participating in trade groups and regulatory committees. They publish insightful technical papers and case studies that inform peers and clients alike about best practices, emerging trends, and new challenges in the insulation market. This thought leadership reinforces their role as industry pace-setters, making their insights and products highly valued and sought after. Trustworthiness is arguably the cornerstone of a successful fiberglass insulation mesh factory. This trust is built on a foundation of quality assurance, transparency, and sustainability. Factories gain client trust by rigorously testing their products to meet and exceed industry standards for performance and safety. They invest in transparent operations, offering factory tours, detailed product specifications, and comprehensive documentation that assures clients of the factory's commitment to quality. Furthermore, a trustworthy factory champions sustainable practices, from sourcing eco-friendly raw materials to implementing energy-efficient manufacturing processes, thereby aligning their production capabilities with environmental stewardship. In conclusion, a fiberglass insulation mesh factory that excels in experience, expertise, authority, and trustworthiness stands out in the competitive market. By continuously improving their processes, fostering a culture of innovation, and maintaining open, honest relationships with clients, these factories not only command respect but also continuously attract new business. They set the benchmark for what clients should expect in terms of quality, service, and reliability, ensuring their place at the forefront of the insulation industry for years to come.

Establishing authority in the fiberglass insulation mesh niche requires more than just expertise and experience—it demands leadership in thought and practice. Factories with a strong presence often contribute to industry standards by participating in trade groups and regulatory committees. They publish insightful technical papers and case studies that inform peers and clients alike about best practices, emerging trends, and new challenges in the insulation market. This thought leadership reinforces their role as industry pace-setters, making their insights and products highly valued and sought after. Trustworthiness is arguably the cornerstone of a successful fiberglass insulation mesh factory. This trust is built on a foundation of quality assurance, transparency, and sustainability. Factories gain client trust by rigorously testing their products to meet and exceed industry standards for performance and safety. They invest in transparent operations, offering factory tours, detailed product specifications, and comprehensive documentation that assures clients of the factory's commitment to quality. Furthermore, a trustworthy factory champions sustainable practices, from sourcing eco-friendly raw materials to implementing energy-efficient manufacturing processes, thereby aligning their production capabilities with environmental stewardship. In conclusion, a fiberglass insulation mesh factory that excels in experience, expertise, authority, and trustworthiness stands out in the competitive market. By continuously improving their processes, fostering a culture of innovation, and maintaining open, honest relationships with clients, these factories not only command respect but also continuously attract new business. They set the benchmark for what clients should expect in terms of quality, service, and reliability, ensuring their place at the forefront of the insulation industry for years to come.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories