1 月 . 06, 2025 19:14 Back to list

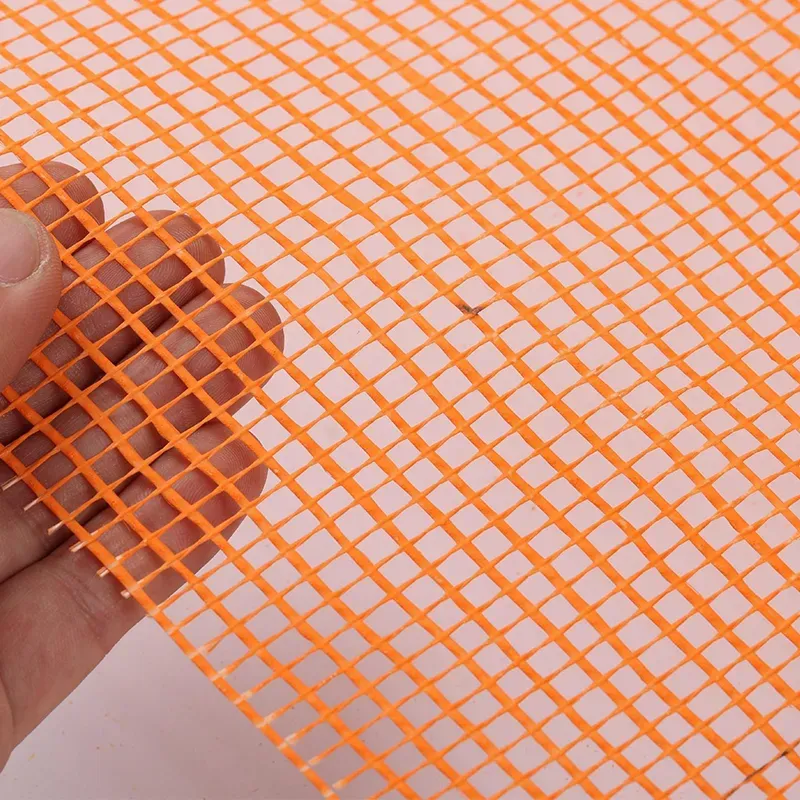

4x4 145g fiberglass mesh roll for Turkey

The Ultimate Guide to Fiber Glass Mesh A Durable Partner in Construction

Fiber glass mesh has emerged as a vital component in the construction industry, renowned for its durability, versatility, and ease of use. When considering materials for enhancing the strength and longevity of architectural structures, fiber glass mesh often stands out as a premier choice. This guide delves into the myriad benefits, applications, and expertise surrounding fiber glass mesh, solidifying its place as a cornerstone in modern construction.

The unmatched durability of fiber glass mesh sets it apart from alternative materials. Composed of finely woven fiberglass yarns, this mesh boasts a high tensile strength, effectively preventing cracking and deformation in plastering and leveling works. Its resistance to alkaline and acid conditions further ensures that structures withstand diverse environmental challenges, safeguarding investments for years to come.

Versatility is another hallmark of fiber glass mesh. Its application is not limited to a single domain; rather, it finds relevance in a wide array of projects. From reinforcing walls, ceilings, and floors to serving as a base for waterproofing membranes, the adaptability of fiber glass mesh is truly remarkable. Its lightweight and flexible nature allow for easy installation, speeding up construction timelines and reducing labor costs.

An integral aspect of its application lies in thermal insulation systems. When integrated into external thermal insulation composite systems (ETICS), fiber glass mesh provides an additional layer of stability, ensuring that insulation panels remain securely in place. This contributes to energy efficiency by maintaining consistent indoor temperatures, ultimately reducing heating and cooling costs.

fiber glass mesh

Furthermore, the use of fiber glass mesh in construction enhances overall structural integrity. By distributing stress across a broader area, this material helps prevent localized damage and prolongs the life of plaster, stucco, or other coatings. This not only boosts the safety and reliability of a building but also reduces maintenance expenses over time.

From an expertise standpoint, working with fiber glass mesh is relatively straightforward, requiring standard tools and techniques that most construction professionals are familiar with. However, for optimal performance, it is crucial to consider the right specifications, such as mesh size and weight, which should align with the specific requirements of your project. Partnering with reputable manufacturers is equally important, as quality control plays a pivotal role in ensuring the mesh complies with industry standards.

Trustworthiness in the context of fiber glass mesh is further reinforced by its widespread adoption and approval from industry experts. Whether in residential buildings, commercial projects, or industrial applications, fiber glass mesh has consistently delivered performance and reliability. Endorsed by architects, engineers, and builders alike, it stands as a testament to proven efficacy and enduring strength.

In conclusion, fiber glass mesh is more than just a product—it's a transformative solution in contemporary construction. By combining experience, expertise, authoritativeness, and trustworthiness, fiber glass mesh not only meets but exceeds the demands of modern architectural challenges. As the industry continues to evolve, its role remains indispensable, offering resilience and versatility in equal measure.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024