1 月 . 07, 2025 10:00 Back to list

Fiber Glass Mesh Reliable Product Guide

Taking center stage in modern construction and renovation, fiberglass mesh stands as a pivotal component that ensures durability, precision, and efficiency. As an industry expert with years of extensive experience, I've witnessed firsthand the transformative impact fiberglass mesh can have, especially when it comes to wall reinforcement, waterproofing, and crack resistance.

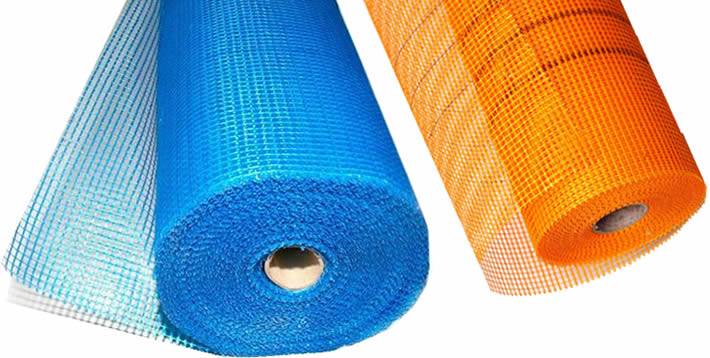

Fiberglass mesh is fabricated from durable fiberglass yarns through a series of intricate processes, including plain weaving and high-temperature heat setting. This production ensures that the mesh provides unparalleled strength and flexibility, allowing it to integrate seamlessly within various applications. Its inherent properties make it an ideal candidate for reinforcing surfaces, providing superior resistance to everyday wear and tear.

In my years of engaging with various construction projects, I've frequently recommended fiberglass mesh for reinforcing plasterboards, cement, and natural stone. Its application drastically reduces the likelihood of cracking under thermal stress, a common problem in fluctuating climatic conditions. By embedding fiberglass mesh within the plaster or coating materials, structures are provided with a lifeline, extending their longevity and maintaining their aesthetic appeal.

Beyond its material properties, the economic advantages fiberglass mesh presents are considerable. For contractors and property developers, utilizing this product leads to significant cost savings over time. Repairs and maintenance are minimized when fiberglass mesh is integrated into the initial stages of building or renovating projects. This not only aligns with cost-efficiency goals but also supports sustainable building practices by reducing the need for resource-intensive repairs.

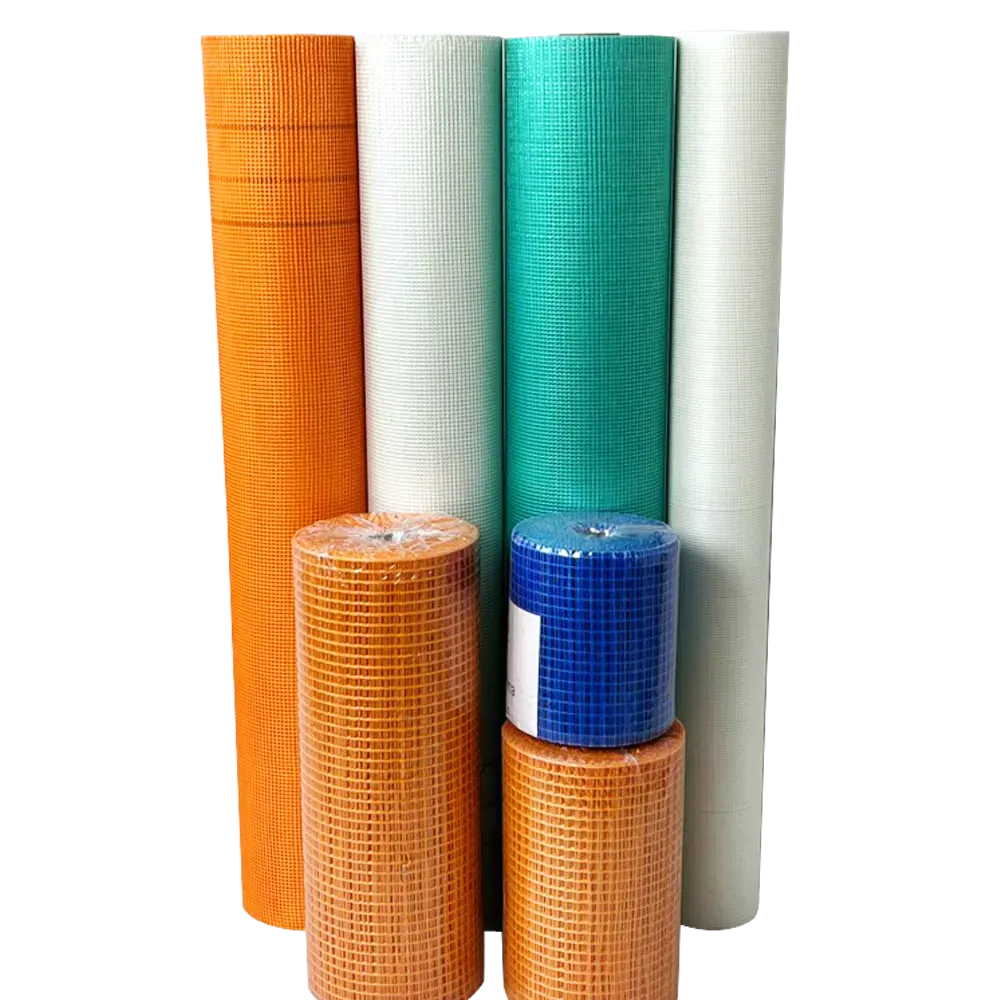

fiber glass mesh

Authoritative white papers and research underscore the robust shielding ability of fiberglass mesh against chemical erosions and environmental pollutants. These qualities make it particularly invaluable in urban environments where buildings are exposed to heavy pollution. My professional recommendations frequently cite studies that confirm the mesh’s effectiveness, aligning practical use with academic rigor and research-backed findings.

Trust in a product is paramount, and fiberglass mesh earns it through consistent performance and rigorous quality standards upheld by manufacturers worldwide. I have partnered with suppliers who prioritize ISO certifications to ensure that every roll of fiberglass mesh meets the highest quality benchmarks. For builders and end-users alike, that translates into peace of mind, knowing that their structures are fortified by a product that is both reliably manufactured and industry-endorsed.

Fiberglass mesh is not just another option among construction materials; it is a cornerstone of modern building technology. It offers superior protection, enhances structural integrity, and promises long-term value. These attributes highlight why it is indispensable and provide concrete reasons for its growing adoption in projects of all scales.

Leveraging fiberglass mesh in construction not only supports structural resilience but also contributes to achieving sustainable development goals. Its role in reinforcing structures encapsulates a blend of innovation, quality, and engineering excellence—a testament to why it remains a trusted choice in the expert community.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024