1 月 . 19, 2025 00:57 Back to list

fiberglass mesh buyer

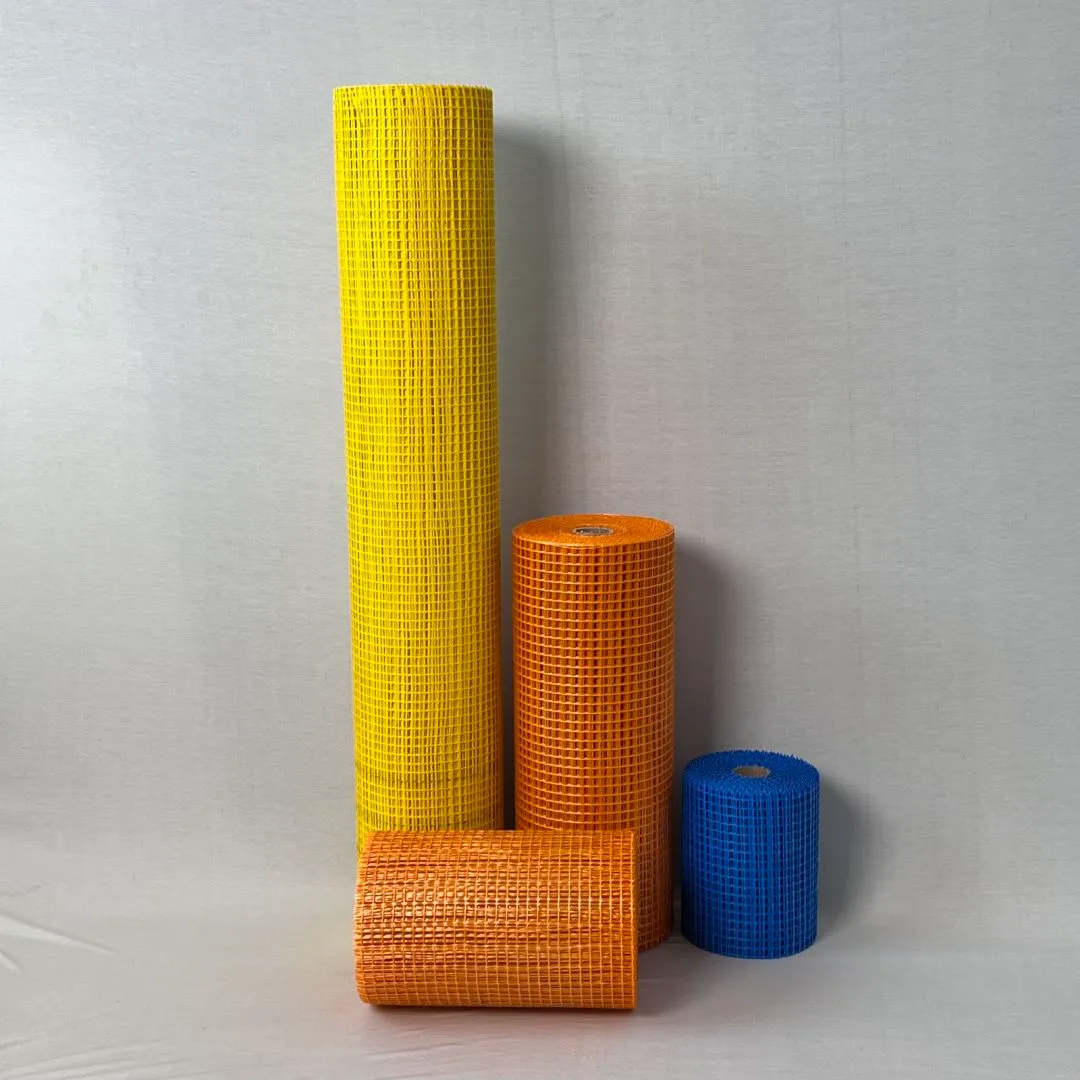

Navigating the world of construction materials can be daunting, especially when sourcing high-quality fiberglass mesh. This essential material, prevalent in reinforcing walls and waterproofing applications, demands a comprehensive understanding before making a purchase. For all potential fiberglass mesh buyers out there, let's delve into what makes this material a vital asset, how to identify top-quality products, and what trends currently shape the market.

Trustworthiness and transparency from suppliers is another crucial element. Reputable sellers are forthright about the sources of their fiberglass materials, manufacturing processes, and even share user testimonials that vouch for the product's durability and efficiency. Engaging with suppliers who provide comprehensive product warranties and post-purchase support can significantly influence purchasing decisions, offering added peace of mind. In terms of market trends, the demand for eco-friendly and sustainable building materials has reshaped the fiberglass mesh market. An increasing number of suppliers now offer products incorporating recycled materials without compromising on quality, aligning with global environmental conservation efforts. Buyers interested in sustainability should inquire about these options, as they can provide the same performance benefits while reducing ecological footprints. Digital transformation within the construction industry has also impacted fiberglass mesh purchasing strategies. Advanced technologies enable real-time tracking of materials, offering insights into supply chain efficiency and delivery timelines. Buyers today are leveraging digital platforms to compare products, check peer reviews, and authenticate the credibility of their suppliers quickly. Establishing partnerships with suppliers who are digitally adept ensures better communication, streamlined operations, and enhanced satisfaction. Finally, understanding the nuanced benefits of fiberglass as opposed to traditional materials is indispensable for contemporary buyers. Unlike metal or wood, fiberglass is non-corrosive, lightweight, and offers excellent thermal insulation properties, making it a versatile choice across various climates and structural requirements. Opting for fiberglass mesh signals an investment in long-term structural health, reduced maintenance costs, and increased property value. As the construction industry evolves, navigating the complexities of choosing the right fiberglass mesh requires a blend of firsthand experience, specialized knowledge, authoritative standards, and principled trust in suppliers. This approach not only guarantees that purchases meet immediate project needs but also stand the test of time, quality, and innovation.

Trustworthiness and transparency from suppliers is another crucial element. Reputable sellers are forthright about the sources of their fiberglass materials, manufacturing processes, and even share user testimonials that vouch for the product's durability and efficiency. Engaging with suppliers who provide comprehensive product warranties and post-purchase support can significantly influence purchasing decisions, offering added peace of mind. In terms of market trends, the demand for eco-friendly and sustainable building materials has reshaped the fiberglass mesh market. An increasing number of suppliers now offer products incorporating recycled materials without compromising on quality, aligning with global environmental conservation efforts. Buyers interested in sustainability should inquire about these options, as they can provide the same performance benefits while reducing ecological footprints. Digital transformation within the construction industry has also impacted fiberglass mesh purchasing strategies. Advanced technologies enable real-time tracking of materials, offering insights into supply chain efficiency and delivery timelines. Buyers today are leveraging digital platforms to compare products, check peer reviews, and authenticate the credibility of their suppliers quickly. Establishing partnerships with suppliers who are digitally adept ensures better communication, streamlined operations, and enhanced satisfaction. Finally, understanding the nuanced benefits of fiberglass as opposed to traditional materials is indispensable for contemporary buyers. Unlike metal or wood, fiberglass is non-corrosive, lightweight, and offers excellent thermal insulation properties, making it a versatile choice across various climates and structural requirements. Opting for fiberglass mesh signals an investment in long-term structural health, reduced maintenance costs, and increased property value. As the construction industry evolves, navigating the complexities of choosing the right fiberglass mesh requires a blend of firsthand experience, specialized knowledge, authoritative standards, and principled trust in suppliers. This approach not only guarantees that purchases meet immediate project needs but also stand the test of time, quality, and innovation.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories