1 月 . 07, 2025 10:20 Back to list

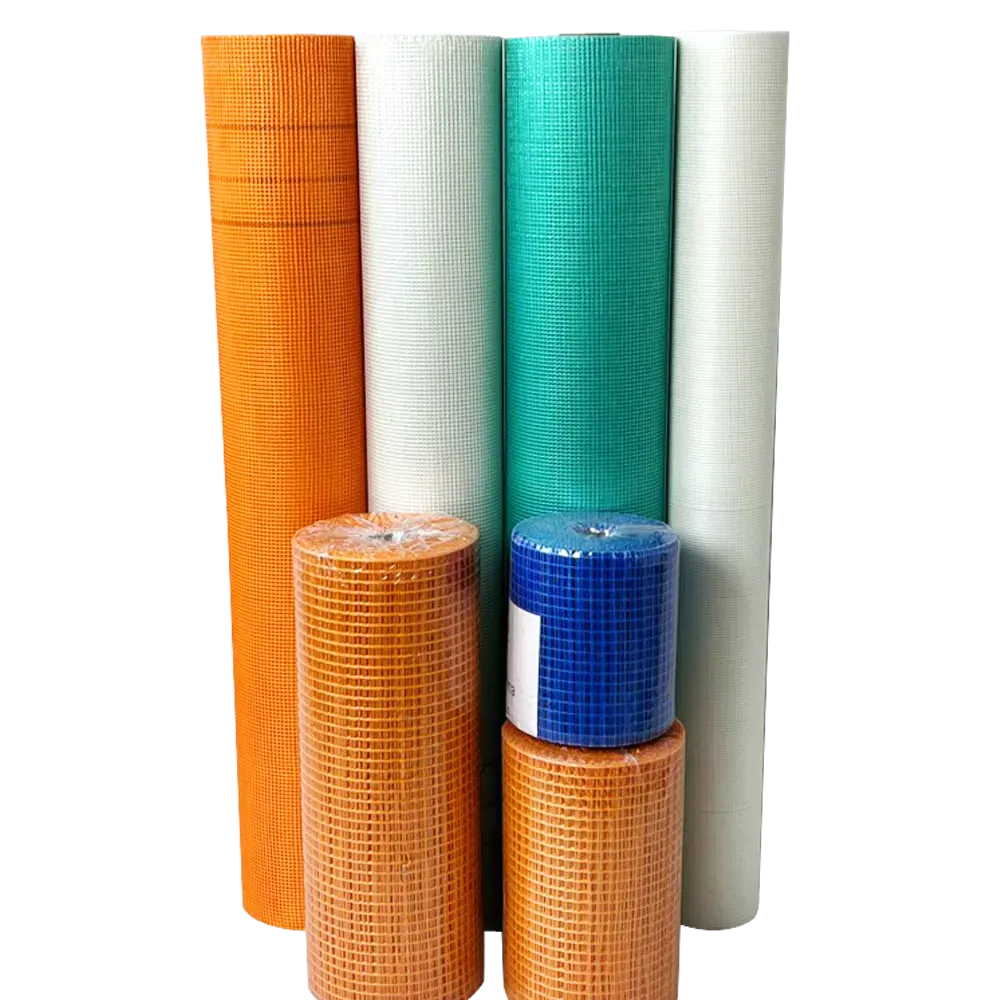

fiberglass mesh colth

Fiberglass mesh cloth has emerged as one of the most essential materials in the construction and renovation industries. Its versatility and durability underscore its widespread use in various applications, from wall reinforcement to waterproofing. This article delves into real experiences, providing an expert perspective on why fiberglass mesh cloth has become indispensable in modern construction.

Vincent, a seasoned construction engineer with over two decades of experience, recounts his initial skepticism about using fiberglass mesh cloth. Years ago, he had relied heavily on traditional metal meshes for structuring. However, after encountering issues with rust and inflexibility, Vincent transitioned to fiberglass mesh cloth. It was a game-changer, he acknowledges, highlighting the material's lightweight nature that did not compromise on strength. This personal experience underscores the material's effectiveness in enhancing structural integrity without adding unnecessary weight.

Professionals in construction understand the importance of long-lasting materials. Fiberglass mesh cloth excels in this regard, offering impressive resistance to alkalis and moisture, which are common concerns in construction settings. Dr. Anna Michaels, a materials scientist specializing in construction materials, points out that fiberglass mesh's chemical composition allows it to resist degradation even in harsh environmental conditions. This expertise backs the material's credibility, making it a top choice for areas requiring additional reinforcement and stability.

Fiberglass mesh cloth's reputation is further bolstered by authoritative endorsements from leading industry associations. The American Concrete Institute and other reputable organizations advocate for its use in critical infrastructure projects. These endorsements highlight trust in the material's reliability from a macro perspective, enhancing its appeal for large-scale projects demanding proven performance and adherence to industry standards.

fiberglass mesh colth

Construction projects often face scrutiny regarding safety and environmental impact. Fiberglass mesh cloth stands out with its non-toxic production process and significant contribution to sustainable building practices. It generates minimal waste compared to alternatives, aligning with the growing need for eco-friendly construction solutions. Companies adopting this material can rightfully claim a commitment to reducing their environmental footprint, as evidenced by the decreased use of resources during installation and its long lifecycle.

Trust plays a pivotal role when selecting construction materials. Contractors like Vincent, who have thoroughly vetted fiberglass mesh cloth through extensive field testing and research, vouch for its reliability. Such real-world validations from experienced professionals ensure that prospective buyers can trust the authenticity and effectiveness of the product.

Fiberglass mesh cloth surpasses traditional materials in flexibility, allowing it to be effectively applied in various shapes and forms, thereby solving complex architectural challenges. It adapts quickly to irregular surfaces, ensuring a seamless application that maintains structural cohesion. Such adaptability is invaluable in modern architectural endeavors, where unique designs are the norm.

In conclusion, fiberglass mesh cloth has secured its place as an essential component in construction due to its combination of strength, flexibility, and environmental responsibility. Stories from seasoned professionals, expert validations, and endorsements from authoritative bodies collectively establish its credibility. When considering materials that promise durability and eco-friendliness, fiberglass mesh cloth triumphs, marking it as a trustworthy solution for the construction industry.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024