2 月 . 16, 2025 01:06 Back to list

Fiberglass Drywall Mesh

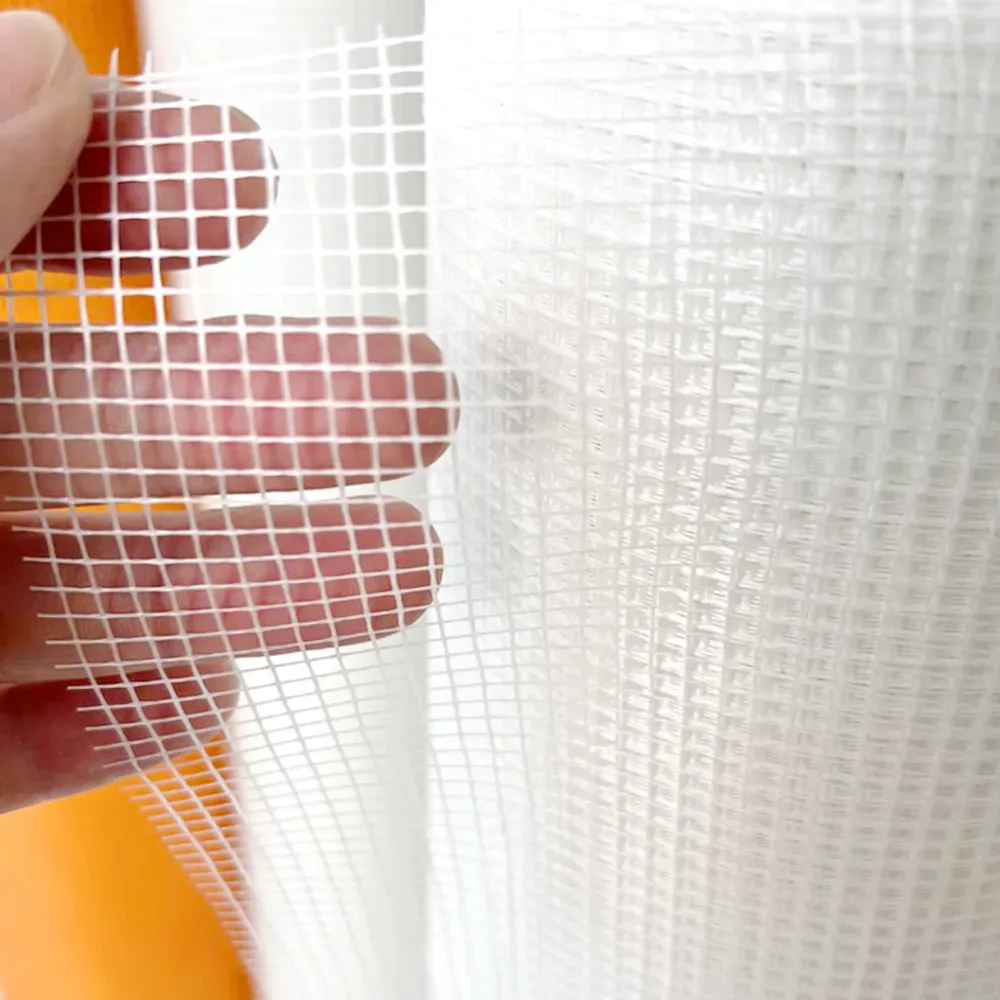

In the realm of modern construction, Exterior Insulation and Finish Systems (EIFS) play a pivotal role in ensuring a building’s thermal efficiency and aesthetic appeal. At the heart of an effective EIFS application is a component often overlooked yet of paramount importance fiberglass mesh. When discussing fiberglass mesh for EIFS manufacturers, several critical factors underline their importance and value, broadening our understanding of the subject.

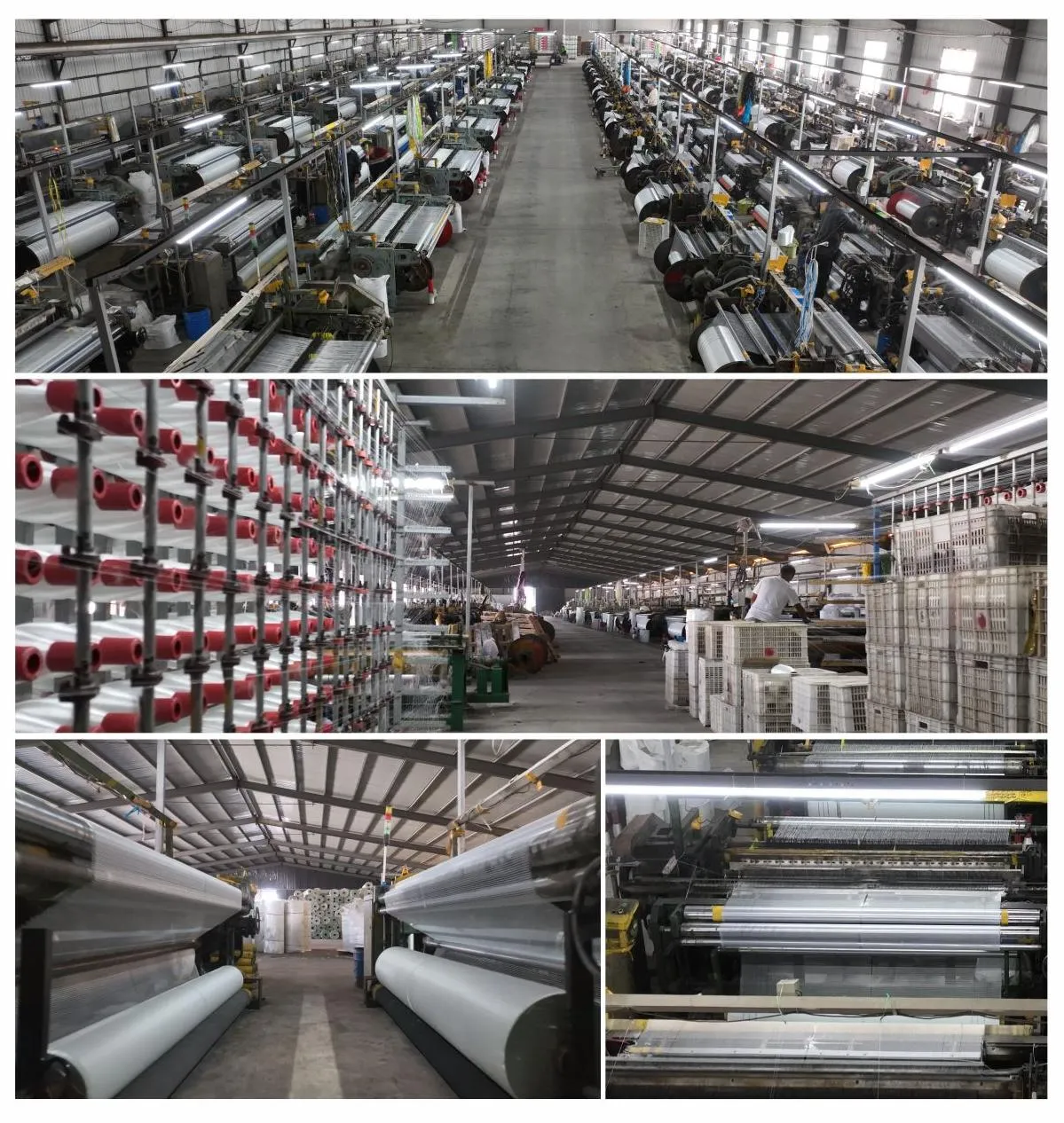

A testament to the expertise of leading manufacturers is their commitment to environmental sustainability. The production of fiberglass mesh entails the use of raw materials like silica sand, an abundant and eco-friendly resource. By optimizing production processes to minimize waste and energy consumption, manufacturers contribute to sustainable building practices. This commitment not only appeals to environmentally conscious businesses but also demonstrates their leadership in responsible manufacturing. Feedback from end-users, such as contractors and builders, further validates the experience and authority of fiberglass mesh for EIFS manufacturers. Real-world application stories highlight the ease of installation and long-term performance of these products under various environmental conditions. Such experiences fortify the reliability of the manufacturers and showcase the practical benefits of using their products. Moreover, ongoing customer support and educational resources provided by manufacturers underscore their dedication to customer success. From technical support during installation to detailed user guides and best practice workshops, manufacturers act as partners to their clientele. This customer-centric approach builds lasting relationships and cultivates a sense of trust, essential for any long-standing business. In conclusion, the intricate interplay of innovation, quality assurance, sustainability, and customer engagement cements the standing of fiberglass mesh for EIFS manufacturers as leaders in the construction industry. Their commitment to delivering superior products that meet the evolving demands of modern architecture exemplifies their expertise and establishes them as authoritative figures in the field. When selecting a fiberglass mesh for EIFS, understanding the manufacturer’s dedication to these principles can significantly impact the success and longevity of the construction project.

A testament to the expertise of leading manufacturers is their commitment to environmental sustainability. The production of fiberglass mesh entails the use of raw materials like silica sand, an abundant and eco-friendly resource. By optimizing production processes to minimize waste and energy consumption, manufacturers contribute to sustainable building practices. This commitment not only appeals to environmentally conscious businesses but also demonstrates their leadership in responsible manufacturing. Feedback from end-users, such as contractors and builders, further validates the experience and authority of fiberglass mesh for EIFS manufacturers. Real-world application stories highlight the ease of installation and long-term performance of these products under various environmental conditions. Such experiences fortify the reliability of the manufacturers and showcase the practical benefits of using their products. Moreover, ongoing customer support and educational resources provided by manufacturers underscore their dedication to customer success. From technical support during installation to detailed user guides and best practice workshops, manufacturers act as partners to their clientele. This customer-centric approach builds lasting relationships and cultivates a sense of trust, essential for any long-standing business. In conclusion, the intricate interplay of innovation, quality assurance, sustainability, and customer engagement cements the standing of fiberglass mesh for EIFS manufacturers as leaders in the construction industry. Their commitment to delivering superior products that meet the evolving demands of modern architecture exemplifies their expertise and establishes them as authoritative figures in the field. When selecting a fiberglass mesh for EIFS, understanding the manufacturer’s dedication to these principles can significantly impact the success and longevity of the construction project.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories