2 月 . 16, 2025 00:28 Back to list

Fiberglass Drywall Mesh

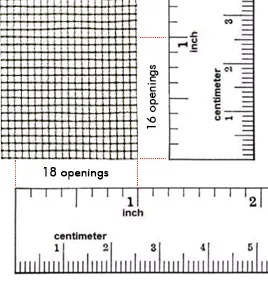

Fiberglass mesh plays a crucial role in the durability and effectiveness of Exterior Insulation and Finish Systems (EIFS). Its integration into EIFS products not only enhances the system's performance but also ensures long-term stability and reliability. As a cornerstone of modern construction, fiberglass mesh boasts characteristics that align perfectly with the demands of EIFS, making it an indispensable component.

Understanding the installation process of fiberglass mesh within EIFS products is pivotal for professionals aiming to deliver quality results. The process involves embedding the mesh in a continuous and wrinkle-free manner within the base coat. It is essential that the overlap between mesh strips is meticulously managed—typically, an overlap of approximately 2.5 to 4 inches is recommended—to prevent weak points that could compromise the system. Proper installation expertise not only ensures the seamless integration of the mesh into the façade system but also enhances the overall performance of the EIFS. Fiberglass mesh's contribution to EIFS also extends to environmental sustainability, a growing concern in today's construction industry. Many fiberglass mesh products are manufactured from materials that are non-toxic and recyclable, which aligns with greener building practices. This environmentally friendly aspect not only reduces the ecological footprint of a construction project but also enhances the appeal of the building to eco-conscious clients. In summary, fiberglass mesh for EIFS products exemplifies the intersection of performance, reliability, and sustainability in modern construction. For thorough expertise, contractors and builders must emphasize product quality, proper installation techniques, and supplier reliability. These measures ensure that the benefits of fiberglass mesh are fully realized, resulting in robust, resilient, and environmentally responsible building exteriors.

Understanding the installation process of fiberglass mesh within EIFS products is pivotal for professionals aiming to deliver quality results. The process involves embedding the mesh in a continuous and wrinkle-free manner within the base coat. It is essential that the overlap between mesh strips is meticulously managed—typically, an overlap of approximately 2.5 to 4 inches is recommended—to prevent weak points that could compromise the system. Proper installation expertise not only ensures the seamless integration of the mesh into the façade system but also enhances the overall performance of the EIFS. Fiberglass mesh's contribution to EIFS also extends to environmental sustainability, a growing concern in today's construction industry. Many fiberglass mesh products are manufactured from materials that are non-toxic and recyclable, which aligns with greener building practices. This environmentally friendly aspect not only reduces the ecological footprint of a construction project but also enhances the appeal of the building to eco-conscious clients. In summary, fiberglass mesh for EIFS products exemplifies the intersection of performance, reliability, and sustainability in modern construction. For thorough expertise, contractors and builders must emphasize product quality, proper installation techniques, and supplier reliability. These measures ensure that the benefits of fiberglass mesh are fully realized, resulting in robust, resilient, and environmentally responsible building exteriors.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories