2 月 . 02, 2025 04:09 Back to list

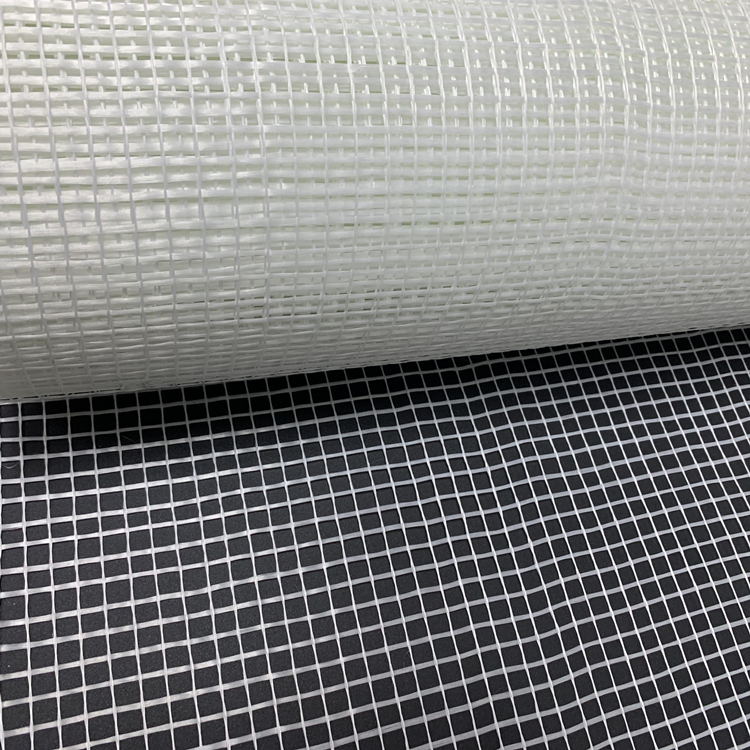

fiberglass mesh netting

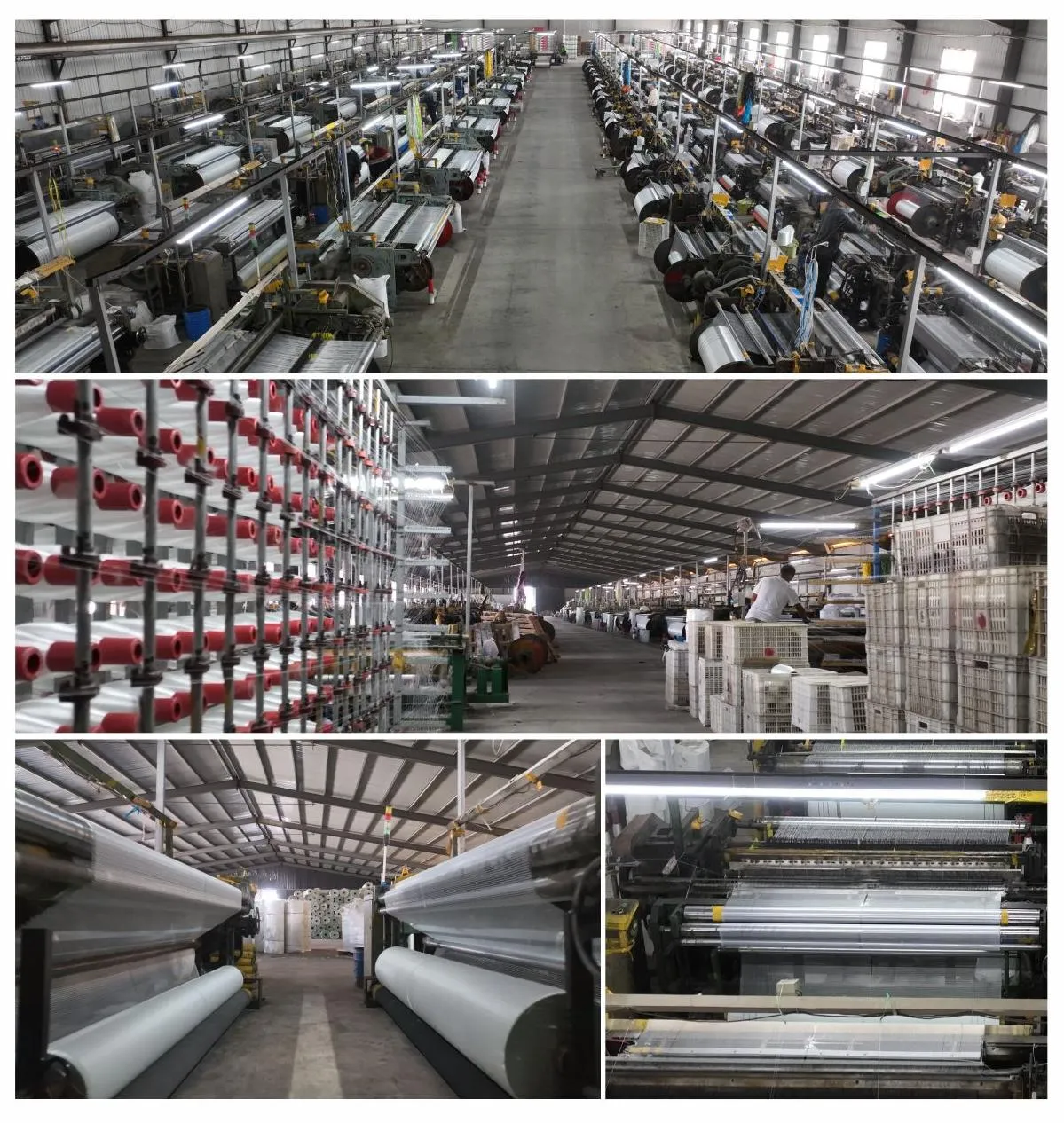

Fiberglass mesh for plastering has become an indispensable component in the construction and renovation industry. This product serves as a vital reinforcement material, enhancing the durability and strength of plastered surfaces. Selecting the right manufacturer is crucial to ensure the mesh meets high standards of quality and performance. Through firsthand experiences and expert insights, this article explores the key factors to consider when evaluating fiberglass mesh for plastering manufacturers.

Trustworthiness is a particularly vital consideration, as it influences long-term business relationships. A trustworthy manufacturer should provide transparent information regarding the mesh's performance characteristics, pricing, and terms of delivery. Moreover, ethical business practices, such as straightforward warranty policies and a commitment to customer service, enhance trust. Reviews and testimonials from industry professionals and past clients serve as valuable indicators of a manufacturer's trustworthiness and reliability over time. For construction professionals seeking dependable fiberglass mesh for plastering, collaboration with a reputable manufacturer ensures the project's success and efficiency. Real-world experiences reveal that reputable manufacturers not only supply quality products but also offer technical support and guidance throughout the selection and application process, thus providing an added layer of assurance. In conclusion, the choice of a fiberglass mesh for plastering manufacturer should be influenced by the product's quality, the manufacturer's expertise, authority, and trustworthiness. Through a strategic evaluation using these criteria, construction professionals can make informed decisions, leading to successful outcomes in both residential and commercial projects. The right manufacturer will not only fulfill product requirements but also act as a partner in achieving optimal construction results.

Trustworthiness is a particularly vital consideration, as it influences long-term business relationships. A trustworthy manufacturer should provide transparent information regarding the mesh's performance characteristics, pricing, and terms of delivery. Moreover, ethical business practices, such as straightforward warranty policies and a commitment to customer service, enhance trust. Reviews and testimonials from industry professionals and past clients serve as valuable indicators of a manufacturer's trustworthiness and reliability over time. For construction professionals seeking dependable fiberglass mesh for plastering, collaboration with a reputable manufacturer ensures the project's success and efficiency. Real-world experiences reveal that reputable manufacturers not only supply quality products but also offer technical support and guidance throughout the selection and application process, thus providing an added layer of assurance. In conclusion, the choice of a fiberglass mesh for plastering manufacturer should be influenced by the product's quality, the manufacturer's expertise, authority, and trustworthiness. Through a strategic evaluation using these criteria, construction professionals can make informed decisions, leading to successful outcomes in both residential and commercial projects. The right manufacturer will not only fulfill product requirements but also act as a partner in achieving optimal construction results.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories