1 月 . 21, 2025 03:26 Back to list

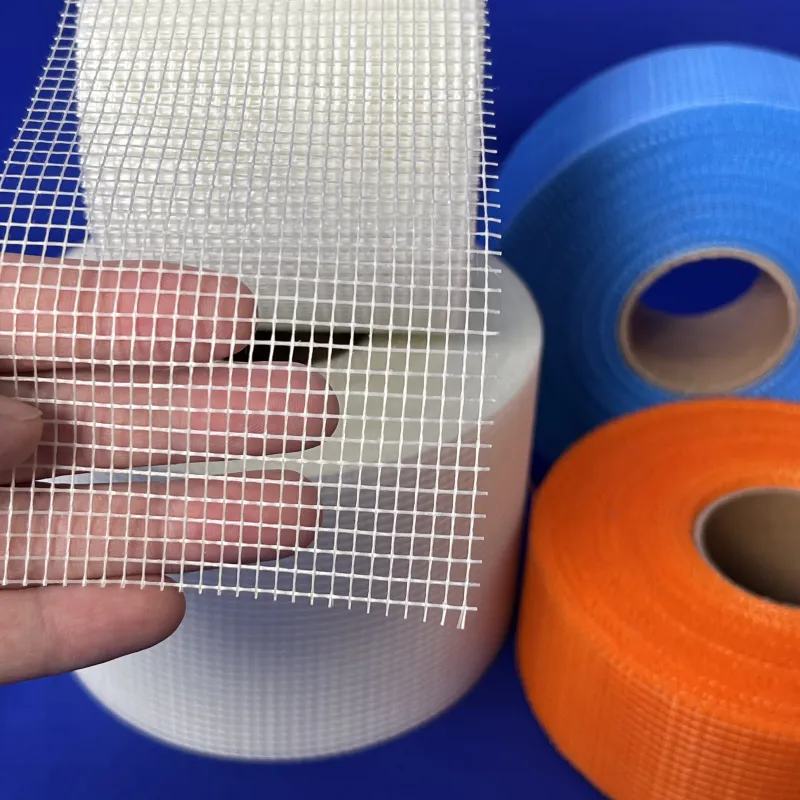

buy concrete fiberglass mesh

Finding the Right Fiberglass Mesh Manufacturer in China An In-Depth Guide

Authoritativeness in the fiberglass mesh industry can also be gauged by the manufacturer's market reputation and client testimonials. Explore online platforms and industry forums where you can find honest feedback from past clients about their experiences. Manufacturers with a positive track record often have longstanding relationships with distributors, architects, and construction firms worldwide. Additionally, they might collaborate with research institutions or industry bodies for continuous improvement, further highlighting their commitment to excellence. Logistical capability is another vital factor. China is a vast country, and manufacturers with a wide-reaching supply chain network can offer more reliable and faster delivery times, catering to international customers efficiently. Check whether the manufacturer has experience with exporting fiberglass mesh to your region and if they can handle various logistical challenges, including customs clearance and compliance with international market regulations. Many manufacturers also provide exemplary after-sales service, which enhances trustworthiness. Look for companies that offer comprehensive customer support, including technical advice on product application and handling, prompt resolution of grievances, and flexible return policies. Such customer-centric practices indicate that the manufacturer values long-term partnerships over short-term transactions. Finally, sustainability practices are becoming increasingly important in the selection process. Manufacturers who prioritize eco-friendly practices, such as using recycled materials or minimizing energy consumption during production, align with global sustainability goals. Responsible manufacturers will often highlight their green initiatives and certifications on their platforms. In conclusion, selecting the right fiberglass mesh manufacturer in China requires a balanced evaluation of expertise, technological advancement, quality control, reputation, logistical capabilities, after-sales service, and sustainability practices. By choosing a manufacturer that excels in these domains, you ensure the procurement of high-quality products that contribute to the success and sustainability of your construction projects.

Authoritativeness in the fiberglass mesh industry can also be gauged by the manufacturer's market reputation and client testimonials. Explore online platforms and industry forums where you can find honest feedback from past clients about their experiences. Manufacturers with a positive track record often have longstanding relationships with distributors, architects, and construction firms worldwide. Additionally, they might collaborate with research institutions or industry bodies for continuous improvement, further highlighting their commitment to excellence. Logistical capability is another vital factor. China is a vast country, and manufacturers with a wide-reaching supply chain network can offer more reliable and faster delivery times, catering to international customers efficiently. Check whether the manufacturer has experience with exporting fiberglass mesh to your region and if they can handle various logistical challenges, including customs clearance and compliance with international market regulations. Many manufacturers also provide exemplary after-sales service, which enhances trustworthiness. Look for companies that offer comprehensive customer support, including technical advice on product application and handling, prompt resolution of grievances, and flexible return policies. Such customer-centric practices indicate that the manufacturer values long-term partnerships over short-term transactions. Finally, sustainability practices are becoming increasingly important in the selection process. Manufacturers who prioritize eco-friendly practices, such as using recycled materials or minimizing energy consumption during production, align with global sustainability goals. Responsible manufacturers will often highlight their green initiatives and certifications on their platforms. In conclusion, selecting the right fiberglass mesh manufacturer in China requires a balanced evaluation of expertise, technological advancement, quality control, reputation, logistical capabilities, after-sales service, and sustainability practices. By choosing a manufacturer that excels in these domains, you ensure the procurement of high-quality products that contribute to the success and sustainability of your construction projects.

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories