2 月 . 15, 2025 12:44 Back to list

buy concrete fiberglass mesh

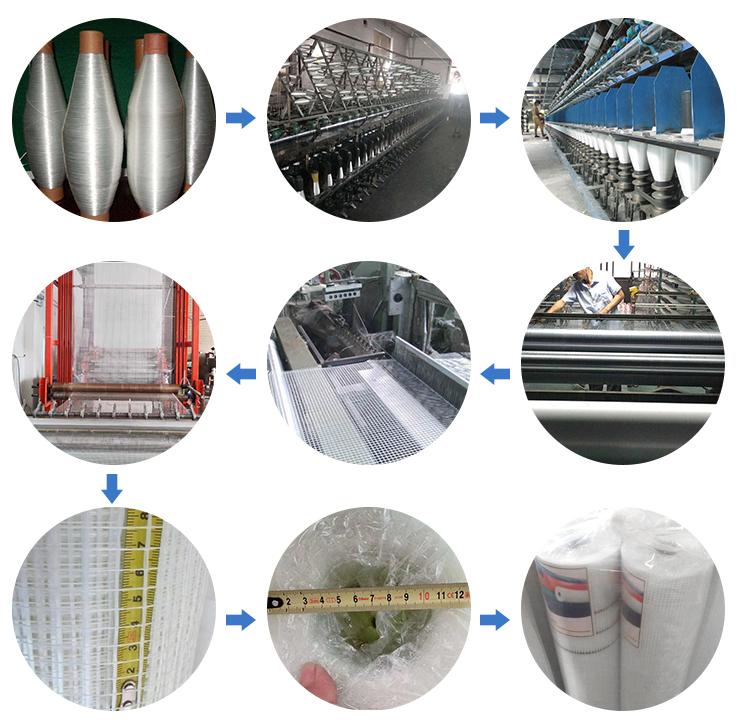

When it comes to sourcing and purchasing fiberglass mesh, understanding the intricacies of pricing can be integral to making informed decisions. Fiberglass mesh, a versatile material known for its strength and durability, is extensively used in construction, particularly for reinforcement and insulation purposes. Here we delve into an in-depth exploration of factors influencing fiberglass mesh prices, blending real-world experience, professional insights, and authoritative knowledge to empower your purchasing decisions.

Volume plays a critical role in determining the overall price. Bulk purchasing often leads to reduced per-unit costs, making it a cost-effective strategy for large-scale projects. Many suppliers offer tiered pricing structures that reward higher purchase volumes, making it prudent for buyers to plan and purchase in bulk whenever feasible. Transportation and logistics fees, an often overlooked component of fiberglass mesh pricing, should not be underestimated. The cost of shipping can vary based on distance, weight, and the handling precautions required for delivery. Choosing local suppliers or those with efficient distribution networks can mitigate these additional expenses and streamline procurement. Economic factors including raw material availability, labor costs, and geopolitical conditions can lead to fluctuations in fiberglass mesh prices. Staying informed about market trends and global supply chain dynamics can provide predictive insights into potential cost changes, enabling more strategic purchasing. In summary, optimizing fiberglass mesh sourcing goes beyond selecting the lowest price. It involves a comprehensive evaluation of quality, specifications, customization needs, and logistical considerations. Building long-term relationships with reputable suppliers, known for their commitment to quality and customer service, further enhances trustworthiness and assures consistent supply. By understanding these key elements, buyers can make educated decisions that not only meet budget constraints but also uphold project standards, ultimately leading to successful construction outcomes.

Volume plays a critical role in determining the overall price. Bulk purchasing often leads to reduced per-unit costs, making it a cost-effective strategy for large-scale projects. Many suppliers offer tiered pricing structures that reward higher purchase volumes, making it prudent for buyers to plan and purchase in bulk whenever feasible. Transportation and logistics fees, an often overlooked component of fiberglass mesh pricing, should not be underestimated. The cost of shipping can vary based on distance, weight, and the handling precautions required for delivery. Choosing local suppliers or those with efficient distribution networks can mitigate these additional expenses and streamline procurement. Economic factors including raw material availability, labor costs, and geopolitical conditions can lead to fluctuations in fiberglass mesh prices. Staying informed about market trends and global supply chain dynamics can provide predictive insights into potential cost changes, enabling more strategic purchasing. In summary, optimizing fiberglass mesh sourcing goes beyond selecting the lowest price. It involves a comprehensive evaluation of quality, specifications, customization needs, and logistical considerations. Building long-term relationships with reputable suppliers, known for their commitment to quality and customer service, further enhances trustworthiness and assures consistent supply. By understanding these key elements, buyers can make educated decisions that not only meet budget constraints but also uphold project standards, ultimately leading to successful construction outcomes.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories