2 月 . 18, 2025 09:02 Back to list

buy concrete fiberglass mesh

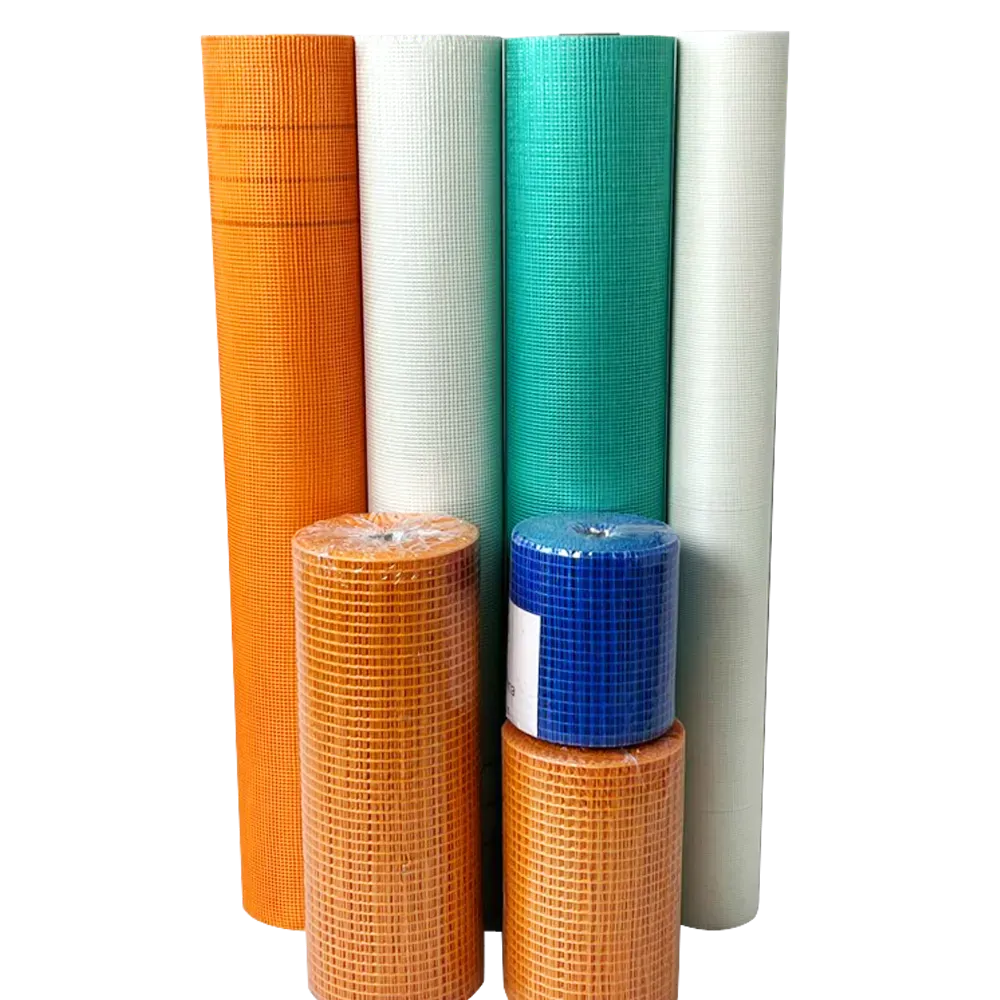

In the world of construction and home improvement, fiberglass mesh has emerged as a vital material known for its versatile applications and cost-effectiveness. Whether it’s for reinforcing wall insulation systems, preventing cracks in floor screeds, or supporting waterproofing membranes, understanding the intricacies of fiberglass mesh and the factors influencing its price can empower buyers to make informed decisions.

The purchasing platform or vendor from which you buy fiberglass mesh can further impact the cost. Direct purchases from manufacturers often lead to lower prices than buying through distributors or third-party retailers. Furthermore, certain vendors might offer discounts or incentives for bulk purchases, which can significantly reduce overall expenditure. For a professional seeking to optimize fiberglass mesh utilization, understanding these price determinants forms the foundation. By delving into manufacturer specifications and assessing your specific needs, you can bridge the gap between cost and functional utility. Engaging with industry forums or consulting with experts may unveil nuanced insights and first-hand experiences that can guide your purchasing decision. Ensuring you procure the right fiberglass mesh involves an analysis of application requirements, environmental conditions, and projected longevity. Selecting an appropriate mesh combats future structural issues and enhances the integrity of the application, which ultimately leads to enhanced customer satisfaction. With the ongoing advancements in construction technology, the demand for high-quality, cost-efficient materials like fiberglass mesh is bound to rise. By staying informed about price trends and leveraging expert knowledge, those in the industry can not only optimize their resource investment but also set benchmarks for quality in their respective domains. In conclusion, navigating the fiberglass mesh market necessitates a balance of economic considerations and technical requirements. By prioritizing quality material and aligning with reputable suppliers, you lay the groundwork for sustainable building solutions, ensuring robust and long-lasting construction outcomes.

The purchasing platform or vendor from which you buy fiberglass mesh can further impact the cost. Direct purchases from manufacturers often lead to lower prices than buying through distributors or third-party retailers. Furthermore, certain vendors might offer discounts or incentives for bulk purchases, which can significantly reduce overall expenditure. For a professional seeking to optimize fiberglass mesh utilization, understanding these price determinants forms the foundation. By delving into manufacturer specifications and assessing your specific needs, you can bridge the gap between cost and functional utility. Engaging with industry forums or consulting with experts may unveil nuanced insights and first-hand experiences that can guide your purchasing decision. Ensuring you procure the right fiberglass mesh involves an analysis of application requirements, environmental conditions, and projected longevity. Selecting an appropriate mesh combats future structural issues and enhances the integrity of the application, which ultimately leads to enhanced customer satisfaction. With the ongoing advancements in construction technology, the demand for high-quality, cost-efficient materials like fiberglass mesh is bound to rise. By staying informed about price trends and leveraging expert knowledge, those in the industry can not only optimize their resource investment but also set benchmarks for quality in their respective domains. In conclusion, navigating the fiberglass mesh market necessitates a balance of economic considerations and technical requirements. By prioritizing quality material and aligning with reputable suppliers, you lay the groundwork for sustainable building solutions, ensuring robust and long-lasting construction outcomes.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories