2 月 . 18, 2025 10:18 Back to list

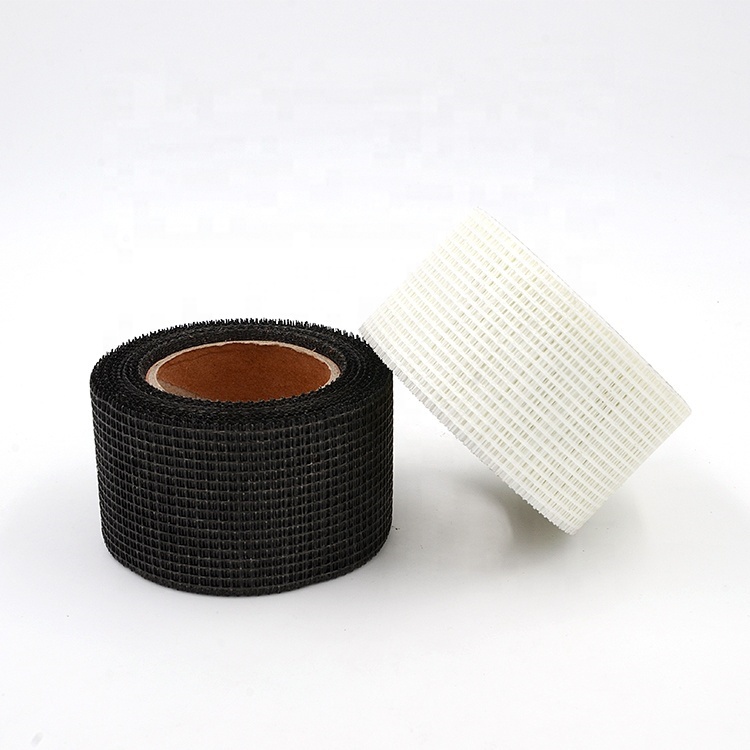

4x4 145g fiberglass mesh roll for Turkey

Fiberglass mesh, an essential component in construction and industrial applications, serves as a crucial reinforcement material. For construction professionals seeking quality at the right price, understanding the dynamics of fiberglass mesh pricing is imperative. This article delves into the factors influencing fiberglass mesh price quotes, offering seasoned insights and authoritative guidance to empower purchasing decisions.

Geographic location also plays a role. Tariffs, import duties, and shipping costs can affect the overall price, especially when sourcing materials internationally. Companies based closer to fiberglass production hubs may benefit from lower transport costs, providing a competitive advantage. Therefore, it’s wise to compare local versus international suppliers to determine the most cost-effective option without compromising quality. When seeking price quotes, it's crucial to engage with suppliers who demonstrate expertise and reliability. Trustworthy suppliers often offer transparent pricing structures and readily share information about the sourcing and production process, building confidence in their products. Request detailed breakdowns of quotes to ensure alignment with project specifications and to avoid unforeseen cost escalations. To reinforce trustworthiness, consider suppliers with proven track records and positive customer testimonials. Engaging in industry forums and peer networks can provide valuable insights into supplier reputations and performance histories. Recommendations from trusted industry partners can lead to more informed supplier selections. Moreover, it is beneficial to explore the full scope of provided services and warranties. Reliable suppliers will back their products with comprehensive warranty terms, reflecting confidence in their quality. Assessing these additional offerings can influence long-term cost savings and assure successful project outcomes. Ultimately, the goal is to strike a balance between cost and quality, ensuring that the fiberglass mesh selected meets project requirements while adhering to budget constraints. By understanding the multiple factors influencing fiberglass mesh price quotes, construction professionals can make well-informed decisions, optimize their procurement strategy, and ultimately enhance their project's success. For real-world application, continuously cultivate relationships with manufacturer representatives and stay abreast of market developments to maintain a competitive edge in the dynamic construction landscape.

Geographic location also plays a role. Tariffs, import duties, and shipping costs can affect the overall price, especially when sourcing materials internationally. Companies based closer to fiberglass production hubs may benefit from lower transport costs, providing a competitive advantage. Therefore, it’s wise to compare local versus international suppliers to determine the most cost-effective option without compromising quality. When seeking price quotes, it's crucial to engage with suppliers who demonstrate expertise and reliability. Trustworthy suppliers often offer transparent pricing structures and readily share information about the sourcing and production process, building confidence in their products. Request detailed breakdowns of quotes to ensure alignment with project specifications and to avoid unforeseen cost escalations. To reinforce trustworthiness, consider suppliers with proven track records and positive customer testimonials. Engaging in industry forums and peer networks can provide valuable insights into supplier reputations and performance histories. Recommendations from trusted industry partners can lead to more informed supplier selections. Moreover, it is beneficial to explore the full scope of provided services and warranties. Reliable suppliers will back their products with comprehensive warranty terms, reflecting confidence in their quality. Assessing these additional offerings can influence long-term cost savings and assure successful project outcomes. Ultimately, the goal is to strike a balance between cost and quality, ensuring that the fiberglass mesh selected meets project requirements while adhering to budget constraints. By understanding the multiple factors influencing fiberglass mesh price quotes, construction professionals can make well-informed decisions, optimize their procurement strategy, and ultimately enhance their project's success. For real-world application, continuously cultivate relationships with manufacturer representatives and stay abreast of market developments to maintain a competitive edge in the dynamic construction landscape.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories