12 月 . 03, 2024 18:19 Back to list

fiberglass mesh price supplier

Understanding Fiberglass Mesh Price Factors and Choosing the Right Supplier

Fiberglass mesh has become a staple in various construction and manufacturing applications due to its strength, durability, and versatility. Whether used for reinforcing walls, providing structural support, or in the production of composite materials, the demand for high-quality fiberglass mesh is constantly rising. However, when looking for suppliers, one of the most significant concerns for buyers is the price. This article delves into the factors that influence the price of fiberglass mesh and offers guidance on selecting the right supplier.

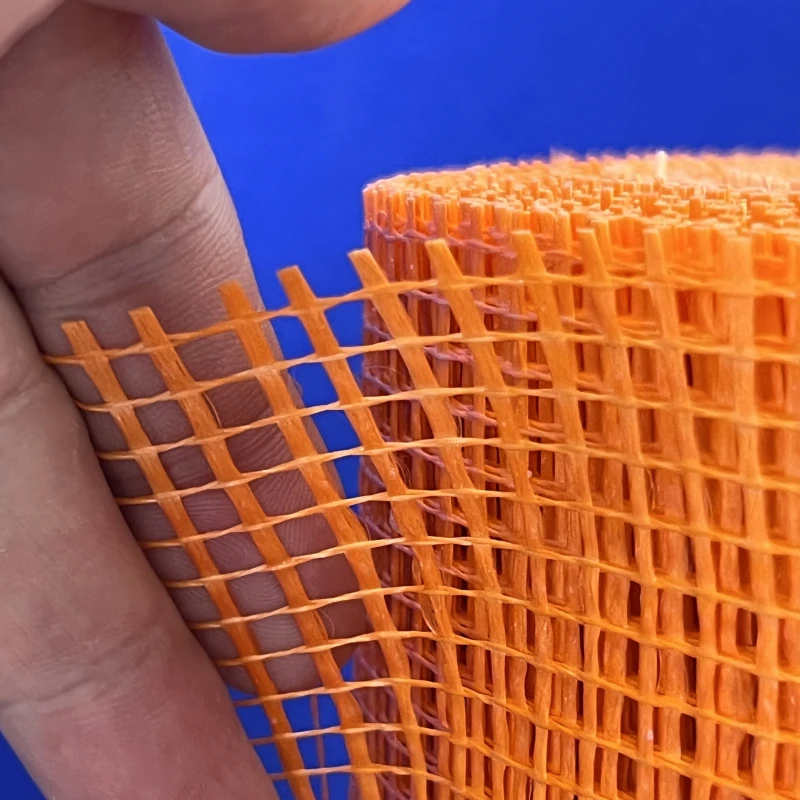

What is Fiberglass Mesh?

Fiberglass mesh is a type of fabric made from woven glass fibers. It is commonly used in construction for stucco and plaster reinforcements, as well as in drywall applications. The durability of fiberglass mesh ensures that it can withstand extreme pressure and environmental conditions, making it ideal for a variety of projects, including exterior wall systems, roofing, and flooring. The mesh is typically coated with a polymer to enhance its water resistance and longevity.

Factors Influencing Price

1. Material Quality The quality of the raw materials used in producing fiberglass mesh significantly impacts its price. High-quality glass fibers will provide better tensile strength and resistance to corrosion, allowing for a more robust end product. Suppliers who use premium materials will generally charge more, but the investment pays off in terms of durability and performance.

2. Weave Type and Density Fiberglass mesh comes in different weave types and densities, which can affect its price. A tighter weave typically offers improved strength and reduced likelihood of tearing, but it may also lead to higher costs. Buyers should consider their specific application to determine whether the added expense of a more robust mesh is necessary.

3. Coating and Treatment Many fiberglass meshes undergo additional treatments or coatings to enhance their properties, such as UV resistance or moisture protection. These additional processes can contribute to the final cost of the product. Buyers should verify whether the added benefits of these coatings align with their project requirements.

4. Order Volume The quantity ordered can impact the overall price per unit. Most suppliers offer tiered pricing, where larger orders result in lower costs per square meter of mesh. For individuals or companies planning to use fiberglass mesh regularly, purchasing in bulk could lead to significant savings.

fiberglass mesh price supplier

5. Logistics and Shipping The location of the supplier and shipping costs can also influence the final price. Local suppliers may offer lower shipping fees, while international orders can add significant costs due to transport and tariffs. It is essential to factor in these logistical aspects when calculating the total investment in fiberglass mesh.

Choosing the Right Supplier

When selecting a supplier for fiberglass mesh, a few critical considerations should guide your decision

- Reputation and Experience Opt for suppliers with a proven track record in the industry. A reputable supplier will usually have positive reviews and testimonials, indicating their reliability in terms of product quality and customer service.

- Product Range A supplier offering a diverse range of fiberglass mesh products can accommodate specific project needs. This includes various grades, weave patterns, and coatings, allowing buyers to find the perfect fit for their applications.

- Customer Support Good customer service is essential when purchasing specialized materials like fiberglass mesh. Suppliers who provide technical support and guidance can help buyers make informed decisions based on their unique project requirements.

- Price Transparency Lastly, choose suppliers who are transparent about their pricing structures. Understanding the cost breakdown can help buyers engage in a fair comparison among different suppliers.

Conclusion

The price of fiberglass mesh is influenced by various factors, including material quality, weave type, order volume, and logistical considerations. By understanding these elements and carefully choosing a reputable supplier, buyers can ensure they obtain high-quality fiberglass mesh that meets their project specifications while staying within budget. With the right approach, investing in fiberglass mesh can yield long-term benefits and contribute to the success of construction and manufacturing projects.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024