12 月 . 03, 2024 15:51 Back to list

fiberglass mesh rolls quotes

Understanding Fiberglass Mesh Rolls An Essential Guide

Fiberglass mesh rolls are a crucial component in various construction and renovation projects, primarily known for their strength, versatility, and resistance to environmental factors. This article will delve into the significance of fiberglass mesh rolls, their applications, and key considerations when obtaining quotes for your needs.

What is Fiberglass Mesh?

Fiberglass mesh is made from woven strands of fiberglass, a material known for its durability and lightweight properties. The mesh structure allows it to provide excellent support while remaining flexible enough to be handled easily. It’s often coated with PVC or another polymer, enhancing its resistance to moisture, chemicals, and UV rays.

Applications of Fiberglass Mesh Rolls

Fiberglass mesh rolls are utilized across a range of sectors

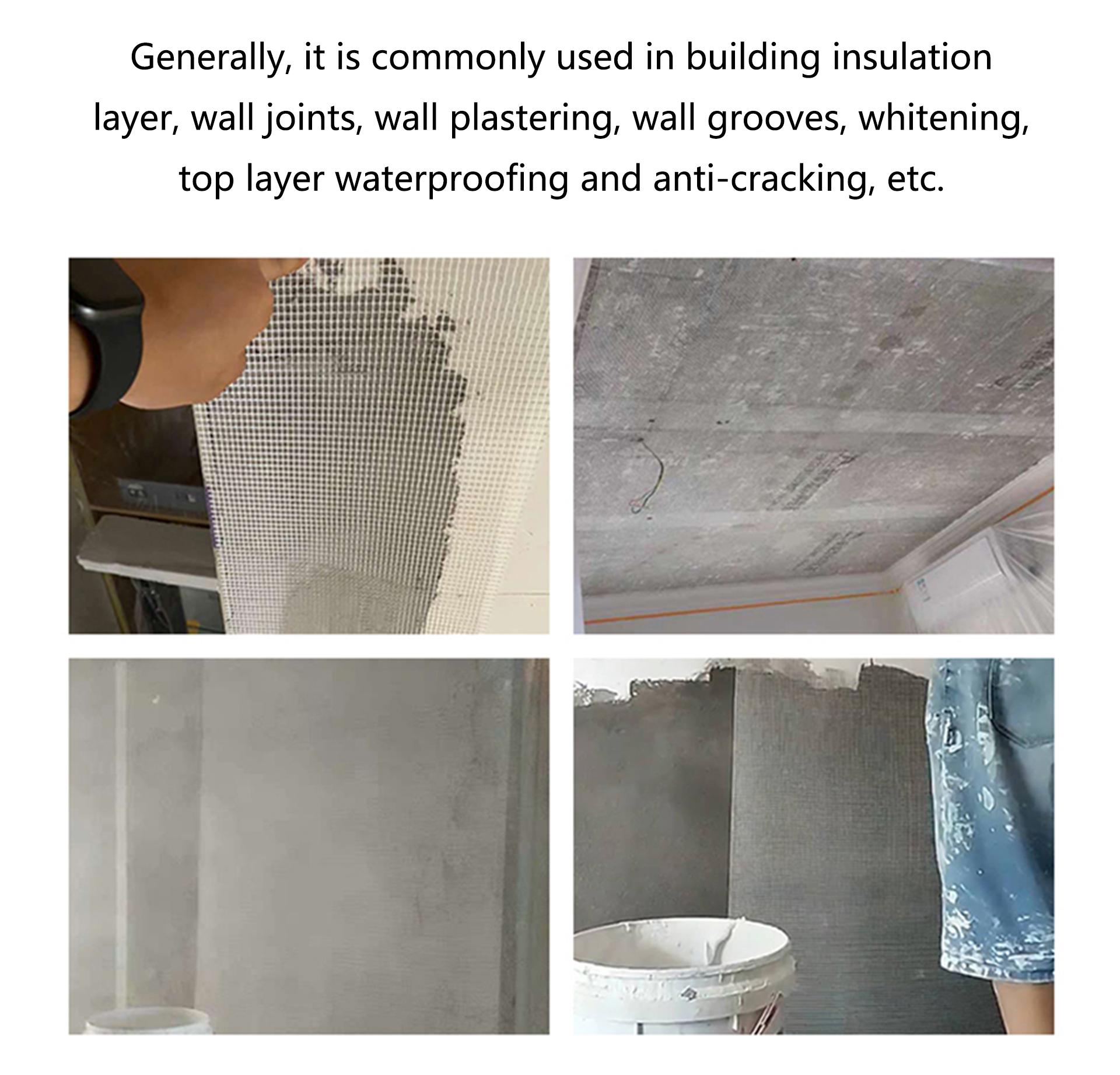

1. Construction and Renovation In construction, fiberglass mesh serves as a reinforcement material in various applications, including stucco systems, wall coatings, and concrete reinforcement. It enhances the structural integrity of buildings and prevents cracking.

2. Roofing Systems Fiberglass mesh is commonly used in roofing systems to reinforce membranes, providing a robust barrier against the elements and extending the lifespan of roofs.

3. Composites Manufacturing The automotive and aerospace industries use fiberglass mesh in the manufacturing of composite materials, thanks to its lightweight properties and strength.

4. Home Improvement Projects DIY enthusiasts frequently utilize fiberglass mesh rolls for repairing walls, ceilings, and floors or for crafting decorative items.

Key Benefits of Fiberglass Mesh Rolls

1. Durability Fiberglass mesh is resistant to corrosion, moisture, and ultraviolet light, making it an ideal choice for both indoor and outdoor applications.

3. Cost-Effectiveness When compared to other reinforcement materials, fiberglass mesh rolls can be more economical, particularly when considering their longevity and effectiveness in preventing damage.

fiberglass mesh rolls quotes

4. Versatility Available in various sizes, thicknesses, and mesh configurations, fiberglass rolls can be tailored to meet specific project requirements.

Factors Influencing Fiberglass Mesh Roll Quotes

When seeking quotes for fiberglass mesh rolls, several factors can influence pricing

1. Material Quality The type of fiberglass used can significantly impact the quote. Higher quality materials may come at a premium but often offer better performance.

2. Roll Size The width and length of the mesh rolls can vary, with larger rolls typically costing more. It’s essential to determine the exact dimensions needed for your project.

3. Custom Specifications If your project requires specific patterns, coatings, or treatments, this can affect the price.

4. Supplier Location Proximity to suppliers can influence shipping costs. Local suppliers might offer lower shipping fees, making them a favorable choice for quick project turnarounds.

5. Order Quantity Bulk orders often come with discounts, so consider purchasing in larger quantities if you have multiple projects planned.

How to Request a Quote

When reaching out for quotes, be prepared to provide the following information

- Project specifications Include dimensions, type of fiberglass mesh required, and intended application. - Quantity needed Specify how many rolls you require. - Delivery requirements Include any timelines or deadlines for delivery.

Conclusion

Fiberglass mesh rolls are a valuable asset in many industries, providing durability and versatility for a variety of applications. By understanding the key factors that affect quotes and being clear about your requirements, you can ensure that you obtain the best possible price and product for your needs. As with any construction material, investing time in research will lead to better results and satisfaction in your projects.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024