2 月 . 14, 2025 16:49 Back to list

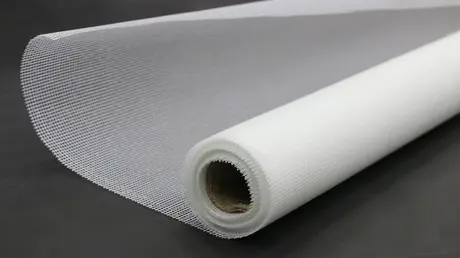

buy concrete fiberglass mesh

Fiberglass mesh sheet products have emerged as essential components in construction, renovation, and various industrial applications due to their versatility, durability, and cost-effectiveness. These products are known for significantly enhancing the structural integrity and longevity of various surfaces ranging from walls to floors. Here’s an expert exploration into why fiberglass mesh sheet products are indispensable and what makes them stand out.

From the perspective of ajourneyed user of fiberglass mesh sheet products, their ease of installation cannot be overstated. Despite their durability and strength, these sheets are lightweight and easy to manipulate, which minimizes labor costs and time spent during application. Their compatibility with various adhesives and cementitious materials also underscores their versatility across different project requirements. On the authority frontier, manufacturers of fiberglass mesh sheets adhere to stringent industry standards to ensure product reliability. These standards often involve testing for tensile strength, durability, and chemical resistance, which builds trust in the product's performance over time. Additionally, industry professionals acknowledge the contribution of fiberglass mesh sheets in achieving sustainable construction goals, as they can significantly improve the thermal performance of buildings when used in insulation systems. Trustworthiness in fiberglass mesh products is further enhanced by their proven track record. Decades of use in a multitude of settings around the globe stand testament to their efficacy and reliability. This history, coupled with ongoing innovations in manufacturing processes (such as coatings that enhance UV resistance or binder materials that improve flexibility), means that consumers and professionals alike can rely on these products for critical structural applications. In summary, fiberglass mesh sheet products are central to modern construction and renovation practices. With their myriad of applications, these products provide unparalleled strength, ease of use, and longevity while meeting contemporary sustainability requirements. As industries continue to evolve, fiberglass mesh sheets remain at the forefront of material innovation, trusted by experts for their proven ability to enhance and protect.

From the perspective of ajourneyed user of fiberglass mesh sheet products, their ease of installation cannot be overstated. Despite their durability and strength, these sheets are lightweight and easy to manipulate, which minimizes labor costs and time spent during application. Their compatibility with various adhesives and cementitious materials also underscores their versatility across different project requirements. On the authority frontier, manufacturers of fiberglass mesh sheets adhere to stringent industry standards to ensure product reliability. These standards often involve testing for tensile strength, durability, and chemical resistance, which builds trust in the product's performance over time. Additionally, industry professionals acknowledge the contribution of fiberglass mesh sheets in achieving sustainable construction goals, as they can significantly improve the thermal performance of buildings when used in insulation systems. Trustworthiness in fiberglass mesh products is further enhanced by their proven track record. Decades of use in a multitude of settings around the globe stand testament to their efficacy and reliability. This history, coupled with ongoing innovations in manufacturing processes (such as coatings that enhance UV resistance or binder materials that improve flexibility), means that consumers and professionals alike can rely on these products for critical structural applications. In summary, fiberglass mesh sheet products are central to modern construction and renovation practices. With their myriad of applications, these products provide unparalleled strength, ease of use, and longevity while meeting contemporary sustainability requirements. As industries continue to evolve, fiberglass mesh sheets remain at the forefront of material innovation, trusted by experts for their proven ability to enhance and protect.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories