2 月 . 10, 2025 10:46 Back to list

fiberglass mesh stucco application manufacturer

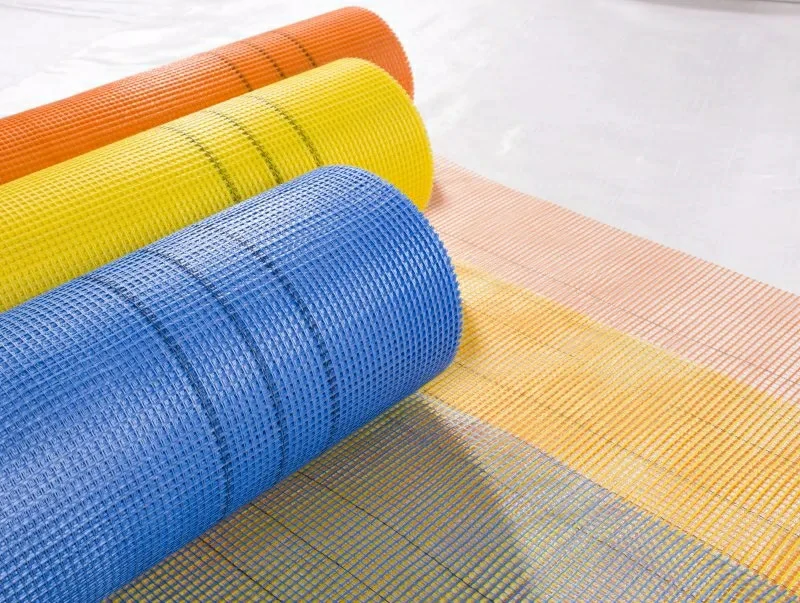

The construction industry has long acknowledged the importance of materials that enhance both durability and efficiency. Among these, fiberglass mesh has emerged as a pivotal component in stucco applications, crafted meticulously by leading manufacturers to meet high standards. The integration of fiberglass mesh in stucco applications serves as a testament to the advancement in construction methodologies, allowing for not only structural integrity but also aesthetic finesse.

The credibility of a fiberglass mesh stucco application manufacturer is often fortified by certifications and adherence to international quality standards. Manufacturers that subject their products to third-party testing and continuous quality audits establish trust within the construction community. Certifications not only validate the performance claims of the products but also assure end-users of their commitment to safety and sustainability. An authoritative manufacturer usually provides comprehensive technical datasheets and support, assisting professionals in making informed decisions tailored to their construction needs. The journey from manufacturing to final application involves stages where trust and expertise are crucial. Users benefit from manufacturers who offer extensive training and resources, ensuring that those involved in the application process are equipped with the necessary skills and knowledge. This educational approach reinforces the overall quality of construction projects, showcasing a manufacturer’s role not just as a supplier, but as a partner in building excellence. In conclusion, the value offered by an esteemed fiberglass mesh stucco application manufacturer extends beyond the product itself. It embodies a commitment to innovation, quality, and continuous support, all while enhancing the core structural framework of modern architecture. The integration of fiberglass mesh in stucco continues to revolutionize how structures withstand environmental tests, promising durability and efficiency crafted by the hands of experts. By fostering an environment where expertise and trust are at the forefront, manufacturers unequivocally enhance the reliability and aesthetic appeal of contemporary construction projects.

The credibility of a fiberglass mesh stucco application manufacturer is often fortified by certifications and adherence to international quality standards. Manufacturers that subject their products to third-party testing and continuous quality audits establish trust within the construction community. Certifications not only validate the performance claims of the products but also assure end-users of their commitment to safety and sustainability. An authoritative manufacturer usually provides comprehensive technical datasheets and support, assisting professionals in making informed decisions tailored to their construction needs. The journey from manufacturing to final application involves stages where trust and expertise are crucial. Users benefit from manufacturers who offer extensive training and resources, ensuring that those involved in the application process are equipped with the necessary skills and knowledge. This educational approach reinforces the overall quality of construction projects, showcasing a manufacturer’s role not just as a supplier, but as a partner in building excellence. In conclusion, the value offered by an esteemed fiberglass mesh stucco application manufacturer extends beyond the product itself. It embodies a commitment to innovation, quality, and continuous support, all while enhancing the core structural framework of modern architecture. The integration of fiberglass mesh in stucco continues to revolutionize how structures withstand environmental tests, promising durability and efficiency crafted by the hands of experts. By fostering an environment where expertise and trust are at the forefront, manufacturers unequivocally enhance the reliability and aesthetic appeal of contemporary construction projects.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories