2 月 . 19, 2025 09:43 Back to list

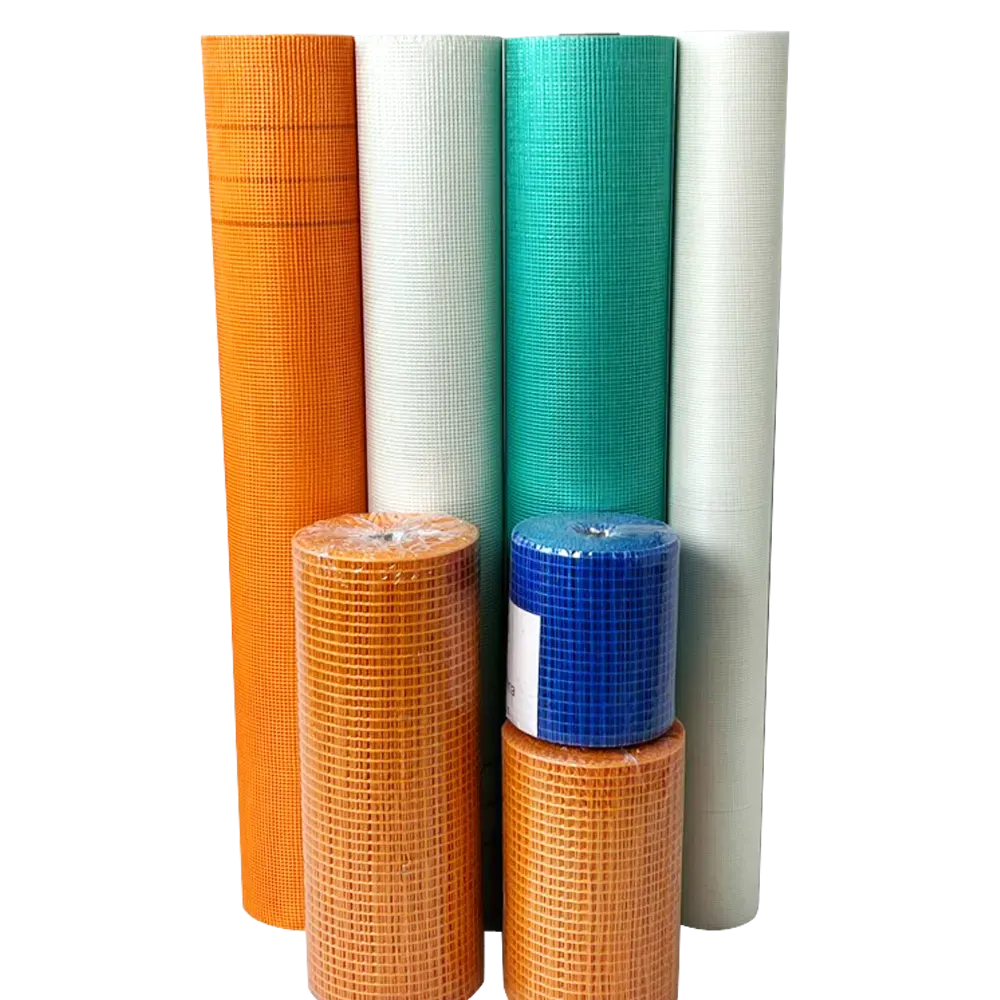

4x4 145g fiberglass mesh roll for Turkey

Fiberglass mesh has established itself as a key component in the stucco and construction industry. Its widespread application isn't a coincidence; rather, it's due to the profound benefits that it offers to both builders and the structures they erect.

Moreover, the trustworthiness of fiberglass mesh is evident in its track record. In homes and commercial buildings worldwide, it has proven its worth. Consumers often question its safety, particularly concerning fire resistance. Here lies another advantage fiberglass mesh does not combust easily, further enhancing its safety profile for residential and commercial buildings alike. Those who have employed fiberglass mesh in their construction endeavors often voice a shared experience of satisfaction with its performance. Contractors note the mesh's ease of use during the application process. By facilitating a hassle-free installation, it allows professionals to maintain project timelines without compromising quality. Furthermore, choosing the right fiberglass mesh is paramount. It's critical to source from reputable manufacturers who guarantee product quality through stringent testing and quality-control measures. The right product can be the difference between a construction marvel and a project fraught with problems. In conclusion, fiberglass mesh stucco products bridge the gap between aesthetic appeal and structural integrity. Embedding this material within stucco not only enhances its visual allure but fortifies buildings against the test of time. For builders and homeowners alike, the decision to use fiberglass mesh is a step towards embracing innovation and ensuring the resilience of their projects. As construction technologies advance, the integration of fiberglass mesh serves as a testament to how traditional building practices can evolve without forfeiting reliability and trust.

Moreover, the trustworthiness of fiberglass mesh is evident in its track record. In homes and commercial buildings worldwide, it has proven its worth. Consumers often question its safety, particularly concerning fire resistance. Here lies another advantage fiberglass mesh does not combust easily, further enhancing its safety profile for residential and commercial buildings alike. Those who have employed fiberglass mesh in their construction endeavors often voice a shared experience of satisfaction with its performance. Contractors note the mesh's ease of use during the application process. By facilitating a hassle-free installation, it allows professionals to maintain project timelines without compromising quality. Furthermore, choosing the right fiberglass mesh is paramount. It's critical to source from reputable manufacturers who guarantee product quality through stringent testing and quality-control measures. The right product can be the difference between a construction marvel and a project fraught with problems. In conclusion, fiberglass mesh stucco products bridge the gap between aesthetic appeal and structural integrity. Embedding this material within stucco not only enhances its visual allure but fortifies buildings against the test of time. For builders and homeowners alike, the decision to use fiberglass mesh is a step towards embracing innovation and ensuring the resilience of their projects. As construction technologies advance, the integration of fiberglass mesh serves as a testament to how traditional building practices can evolve without forfeiting reliability and trust.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories