2 月 . 14, 2025 10:08 Back to list

fiberglass mesh tape for ducts companies

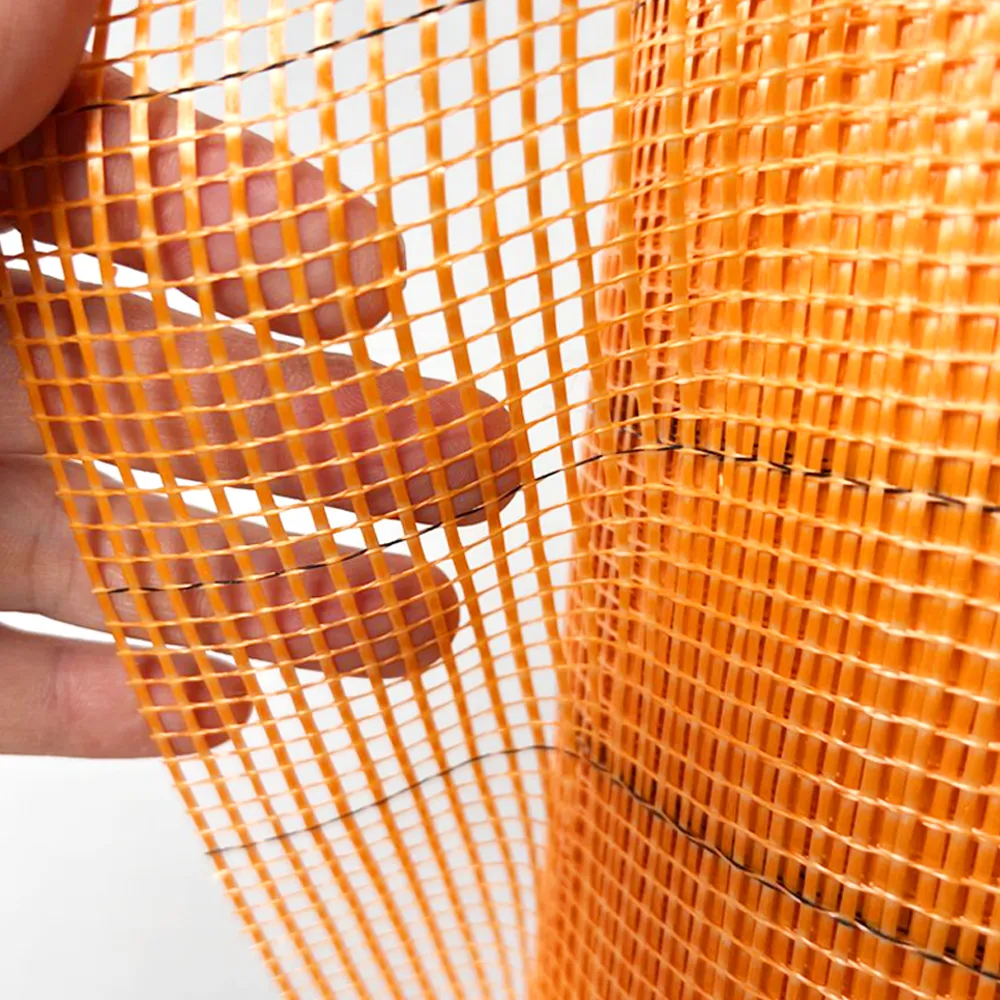

Navigating the intricate world of HVAC systems requires a nuanced understanding of the components that ensure efficiency and longevity. Fiberglass mesh tape is one such component, integral in sealing ducts to maintain system integrity. This product is pivotal for any company operating in HVAC maintenance or installation, demanding attention to detail and a commitment to quality.

Expertise in handling fiberglass mesh tape involves understanding environmental impacts as well. Companies should be aware of any potential emissions from degraded tapes, particularly in older buildings. Selecting fiberglass mesh tape with low VOC emissions contributes to a healthier indoor environment, aligning with green building initiatives. From a trustworthiness perspective, manufacturers that disclose detailed information about their tape's composition, including VOC levels and heat resistance ratings, build credibility with HVAC professionals and clients alike. Transparent communication regarding the tape's origins, whether it’s locally sourced or imported, can further cement trust. Certification by recognized industry bodies can distinguish reputable suppliers, serving as a testament to the quality and reliability of their products. Additionally, training technicians in the correct application of fiberglass mesh tape is instrumental. Comprehensive training programs should cover best practices and troubleshooting advice—for instance, identifying when high humidity might necessitate reapplication. This approach enhances both the expertise of the workforce and the integrity of the application process. To solidify a company's authority in the field, ongoing research and development should be emphasized. Staying ahead with innovations in adhesives and mesh technology can not only improve product offerings but also provide a competitive edge. Partnering with research institutions or participating in industry forums can place a company at the forefront of technological advancements in HVAC systems. In conclusion, fiberglass mesh tape is a cornerstone in the construction and maintenance of duct systems, integral for ensuring operational efficiency and energy conservation. Companies focusing on this niche must prioritize product quality, application expertise, compliance, and environmental responsibility. By doing so, they enhance their standing in an ever-evolving industry, delivering unparalleled service and durable systems to their clientele.

Expertise in handling fiberglass mesh tape involves understanding environmental impacts as well. Companies should be aware of any potential emissions from degraded tapes, particularly in older buildings. Selecting fiberglass mesh tape with low VOC emissions contributes to a healthier indoor environment, aligning with green building initiatives. From a trustworthiness perspective, manufacturers that disclose detailed information about their tape's composition, including VOC levels and heat resistance ratings, build credibility with HVAC professionals and clients alike. Transparent communication regarding the tape's origins, whether it’s locally sourced or imported, can further cement trust. Certification by recognized industry bodies can distinguish reputable suppliers, serving as a testament to the quality and reliability of their products. Additionally, training technicians in the correct application of fiberglass mesh tape is instrumental. Comprehensive training programs should cover best practices and troubleshooting advice—for instance, identifying when high humidity might necessitate reapplication. This approach enhances both the expertise of the workforce and the integrity of the application process. To solidify a company's authority in the field, ongoing research and development should be emphasized. Staying ahead with innovations in adhesives and mesh technology can not only improve product offerings but also provide a competitive edge. Partnering with research institutions or participating in industry forums can place a company at the forefront of technological advancements in HVAC systems. In conclusion, fiberglass mesh tape is a cornerstone in the construction and maintenance of duct systems, integral for ensuring operational efficiency and energy conservation. Companies focusing on this niche must prioritize product quality, application expertise, compliance, and environmental responsibility. By doing so, they enhance their standing in an ever-evolving industry, delivering unparalleled service and durable systems to their clientele.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories