2 月 . 13, 2025 11:28 Back to list

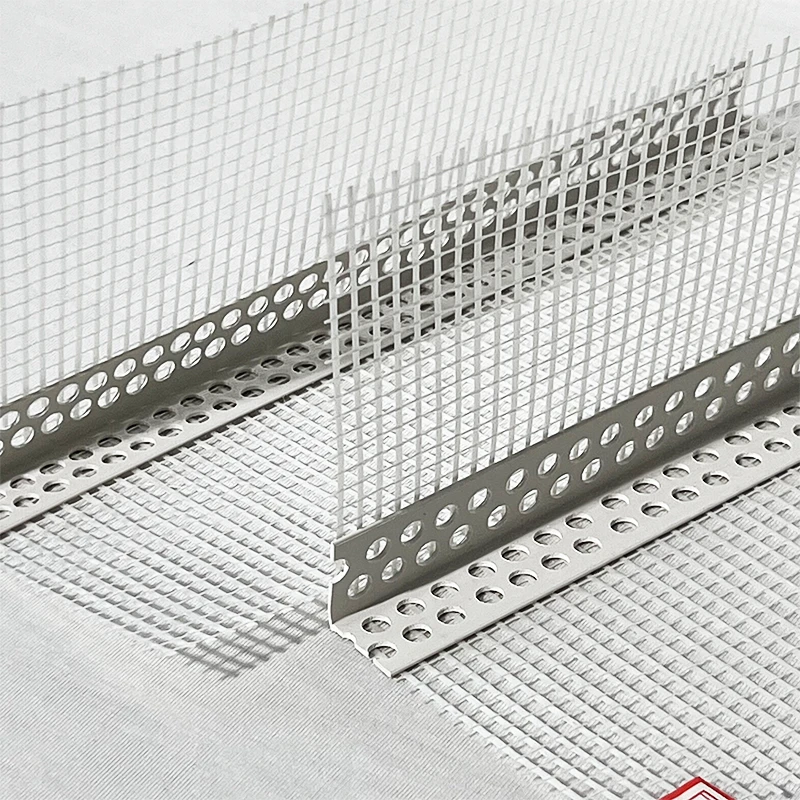

fiberglass mesh tape for tile manufacturer

In the intricate world of tile installation, the foundational components often dictate the longevity and quality of the outcome. One such component, frequently underestimated, is the fiberglass mesh tape. Particularly for tile manufacturers, selecting and using the right fiberglass mesh tape can be a game-changer, not only in the quality of the installation but also in enhancing customer satisfaction and long-term brand loyalty.

Moreover, authoritative manufacturers often collaborate with leading industry experts and participate in ongoing research to innovate and refine fiberglass mesh tapes. The continuous development of new formulations and the refinement of manufacturing processes underscore their commitment to excellence and authority in this field. By staying ahead of industry trends and technological advancements, they ensure their products consistently meet or exceed industry standards. Trustworthiness in fiberglass mesh tape production hinges on rigorous quality control protocols and the transparent sourcing of raw materials. Trustworthy manufacturers are often certified by relevant industry bodies, which signals their adherence to best practices and quality benchmarks. This certification offers peace of mind to their customers, who can trust that the products are reliable and safe for use in various tiling applications. Product trials and case studies further reinforce the credibility of a reputable fiberglass mesh tape manufacturer. By showcasing past projects where their tapes have significantly reduced tile failures or contributed to exemplary installations, these manufacturers can provide tangible proof of their product's effectiveness. This data not only assists installers in choosing the right product but also helps tile manufacturers in forming strategic partnerships that enhance their product lines. In summary, fiberglass mesh tape is not just a supplementary product in tile installations; it is a cornerstone of quality and longevity. Tile manufacturers who understand and implement the right type of fiberglass mesh tape are seen as pioneers of quality craftsmanship. Their commitment to research, quality, and customer satisfaction underscores the Experience, Expertise, Authoritativeness, and Trustworthiness that are paramount in this industry. By focusing on these aspects, they not only enhance their market position but also ensure lasting relationships with their customers, ultimately leading to sustained success in the competitive world of tile manufacturing.

Moreover, authoritative manufacturers often collaborate with leading industry experts and participate in ongoing research to innovate and refine fiberglass mesh tapes. The continuous development of new formulations and the refinement of manufacturing processes underscore their commitment to excellence and authority in this field. By staying ahead of industry trends and technological advancements, they ensure their products consistently meet or exceed industry standards. Trustworthiness in fiberglass mesh tape production hinges on rigorous quality control protocols and the transparent sourcing of raw materials. Trustworthy manufacturers are often certified by relevant industry bodies, which signals their adherence to best practices and quality benchmarks. This certification offers peace of mind to their customers, who can trust that the products are reliable and safe for use in various tiling applications. Product trials and case studies further reinforce the credibility of a reputable fiberglass mesh tape manufacturer. By showcasing past projects where their tapes have significantly reduced tile failures or contributed to exemplary installations, these manufacturers can provide tangible proof of their product's effectiveness. This data not only assists installers in choosing the right product but also helps tile manufacturers in forming strategic partnerships that enhance their product lines. In summary, fiberglass mesh tape is not just a supplementary product in tile installations; it is a cornerstone of quality and longevity. Tile manufacturers who understand and implement the right type of fiberglass mesh tape are seen as pioneers of quality craftsmanship. Their commitment to research, quality, and customer satisfaction underscores the Experience, Expertise, Authoritativeness, and Trustworthiness that are paramount in this industry. By focusing on these aspects, they not only enhance their market position but also ensure lasting relationships with their customers, ultimately leading to sustained success in the competitive world of tile manufacturing.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories