2 月 . 20, 2025 10:06 Back to list

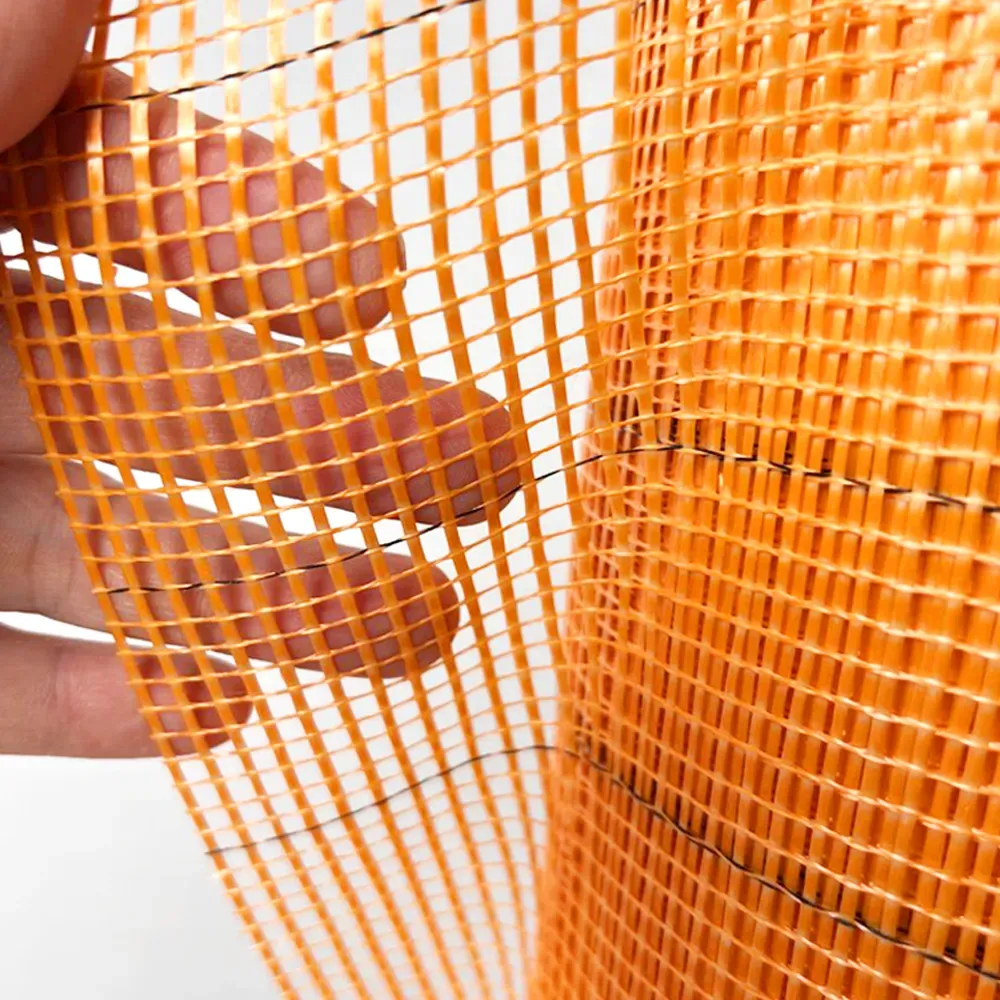

fiberglass wall mesh

Choosing the right materials for construction or renovation can be quite daunting, especially when it comes to reinforcing and finishing surfaces. Fiberglass plaster mesh, a vital component often overlooked, plays a crucial role in ensuring stability and durability in various building projects. This mesh is not only pivotal in maintaining the structural integrity of plaster surfaces but also essential for preventing cracks. Understanding the attributes and benefits of fiberglass plaster mesh can aid in making informed decisions for your construction needs.

One authoritative aspect of fiberglass plaster mesh is its resistance to alkaline compounds. Plasters and cements tend to have high alkaline levels, which can slowly degrade lesser materials. The chemical treatments applied to fiberglass mesh render it resistant to alkalinity, making it a durable choice that withstands the test of time. This contributes significantly to the trustworthiness of fiberglass plaster mesh as a reliable material in construction, ensuring that surfaces remain intact and aesthetically pleasing for many years. Incorporating fiberglass plaster mesh in construction projects resonates with long-term savings, not just in repairs, but also in maintenance. A properly reinforced wall, ceiling, or floor minimizes the chances of crack formations, which, if left unchecked, can lead to more significant structural issues. Therefore, using fiberglass plaster mesh is akin to investing in the future well-being of the structure, embodying both cost-effectiveness and durability. For those seeking quality and efficiency in their projects, seeking quotes for fiberglass plaster mesh from reputable suppliers becomes a priority. Expert suppliers offer a variety of mesh options that detail the density, width, and specific applications suitable for different project requirements. Obtaining these details ensures you select the appropriate fiberglass mesh that aligns perfectly with your construction needs and budgets. In conclusion, fiberglass plaster mesh emerges as a necessary component for anyone serious about the structural integrity and longevity of their construction projects. Its combination of strength, flexibility, ease of application, and chemical resistance speaks volumes about its superiority over other types of mesh. Whether you’re a construction professional or a DIY enthusiast, incorporating fiberglass plaster mesh into your projects guarantees surfaces that stand the test of time, backed by the trust and expertise of industry specialists.

One authoritative aspect of fiberglass plaster mesh is its resistance to alkaline compounds. Plasters and cements tend to have high alkaline levels, which can slowly degrade lesser materials. The chemical treatments applied to fiberglass mesh render it resistant to alkalinity, making it a durable choice that withstands the test of time. This contributes significantly to the trustworthiness of fiberglass plaster mesh as a reliable material in construction, ensuring that surfaces remain intact and aesthetically pleasing for many years. Incorporating fiberglass plaster mesh in construction projects resonates with long-term savings, not just in repairs, but also in maintenance. A properly reinforced wall, ceiling, or floor minimizes the chances of crack formations, which, if left unchecked, can lead to more significant structural issues. Therefore, using fiberglass plaster mesh is akin to investing in the future well-being of the structure, embodying both cost-effectiveness and durability. For those seeking quality and efficiency in their projects, seeking quotes for fiberglass plaster mesh from reputable suppliers becomes a priority. Expert suppliers offer a variety of mesh options that detail the density, width, and specific applications suitable for different project requirements. Obtaining these details ensures you select the appropriate fiberglass mesh that aligns perfectly with your construction needs and budgets. In conclusion, fiberglass plaster mesh emerges as a necessary component for anyone serious about the structural integrity and longevity of their construction projects. Its combination of strength, flexibility, ease of application, and chemical resistance speaks volumes about its superiority over other types of mesh. Whether you’re a construction professional or a DIY enthusiast, incorporating fiberglass plaster mesh into your projects guarantees surfaces that stand the test of time, backed by the trust and expertise of industry specialists.

Prev:

Next:

Latest news

-

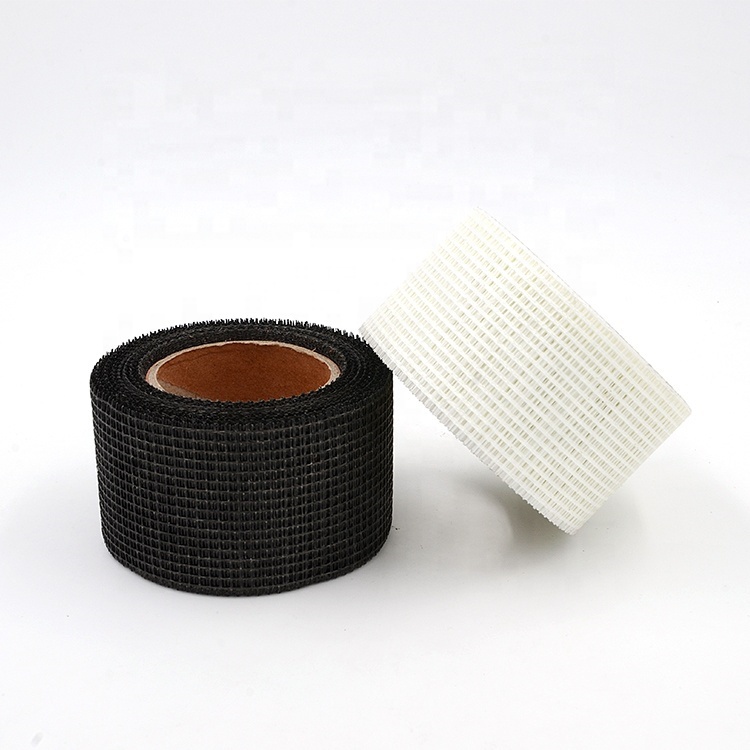

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories