2 月 . 01, 2025 02:08 Back to list

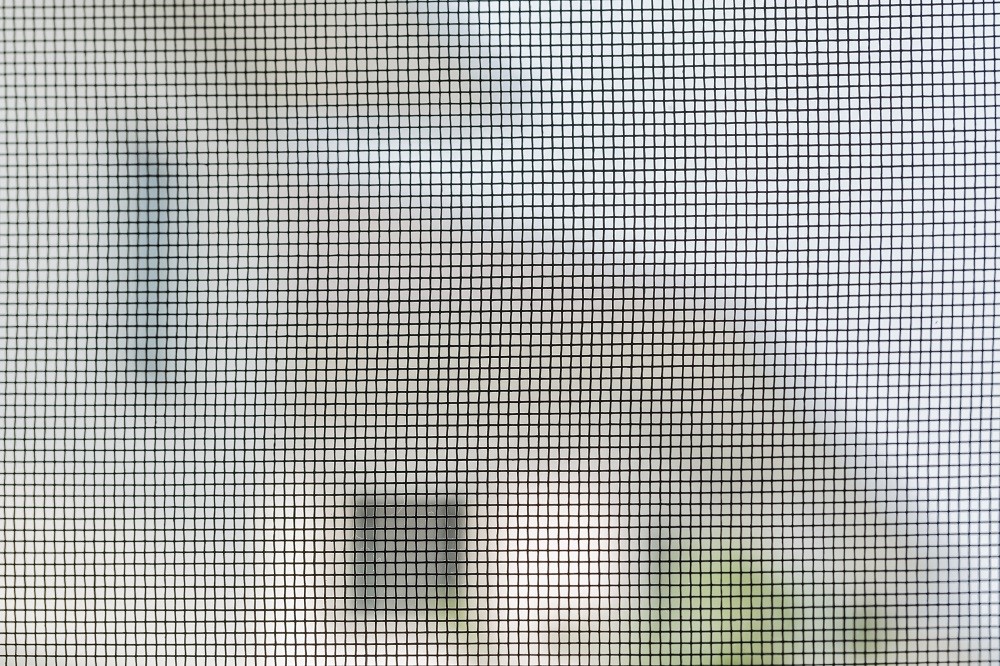

fiberglass sticky mesh pricelist

Navigating the world of fiberglass sticky mesh requires an informed approach, especially when considering purchases for industrial or construction projects. This product plays a crucial role in various applications, such as reinforcing structures, waterproofing surfaces, or providing stability and strength to plasterboard and other construction materials. Here's what you need to know about fiberglass sticky mesh, based on the principles that emphasize Experience, Expertise, Authoritativeness, and Trustworthiness.

Trustworthiness in the context of fiberglass sticky mesh is demonstrated through transparency in pricing and product sourcing. Buyers are encouraged to procure from reputable suppliers who provide detailed pricing lists and ensure that their products meet necessary safety and environmental standards. Many suppliers offer bulk purchasing options, presenting cost-effective solutions for large-scale projects. Engaging with suppliers who maintain open lines of communication and offer comprehensive customer support fortifies trust, making the purchasing process smoother and more secure. Recently, the market has seen innovations in the production of fiberglass sticky mesh, such as enhanced adhesive properties and eco-friendly manufacturing processes. These developments not only enhance the performance of the product but also align with growing sustainability standards in construction. Keeping abreast of these innovations is crucial for professionals who aim to implement the most up-to-date solutions in their projects. Moreover, consumer reviews and case studies serve as valuable tools in building trust and reliability. Feedback from projects that have successfully utilized fiberglass sticky mesh can offer insights into optimal application techniques and potential challenges. By analyzing these firsthand accounts, professionals can adapt their strategies to maximize efficiency and strengthen their craftsmanship. As demand for reinforced building materials continues to rise, the importance of fiberglass sticky mesh will undoubtedly increase. From minor renovations to large construction undertakings, this material offers an essential solution for creating durable, resilient structures. When selecting fiberglass sticky mesh, it is vital to engage with knowledgeable suppliers, evaluate technical specifications, and consider cost-effective purchasing strategies. By leveraging experience, expertise, authority, and trust, stakeholders can ensure they choose the best fiberglass sticky mesh for their needs, supporting successful project outcomes and advancing industry standards.

Trustworthiness in the context of fiberglass sticky mesh is demonstrated through transparency in pricing and product sourcing. Buyers are encouraged to procure from reputable suppliers who provide detailed pricing lists and ensure that their products meet necessary safety and environmental standards. Many suppliers offer bulk purchasing options, presenting cost-effective solutions for large-scale projects. Engaging with suppliers who maintain open lines of communication and offer comprehensive customer support fortifies trust, making the purchasing process smoother and more secure. Recently, the market has seen innovations in the production of fiberglass sticky mesh, such as enhanced adhesive properties and eco-friendly manufacturing processes. These developments not only enhance the performance of the product but also align with growing sustainability standards in construction. Keeping abreast of these innovations is crucial for professionals who aim to implement the most up-to-date solutions in their projects. Moreover, consumer reviews and case studies serve as valuable tools in building trust and reliability. Feedback from projects that have successfully utilized fiberglass sticky mesh can offer insights into optimal application techniques and potential challenges. By analyzing these firsthand accounts, professionals can adapt their strategies to maximize efficiency and strengthen their craftsmanship. As demand for reinforced building materials continues to rise, the importance of fiberglass sticky mesh will undoubtedly increase. From minor renovations to large construction undertakings, this material offers an essential solution for creating durable, resilient structures. When selecting fiberglass sticky mesh, it is vital to engage with knowledgeable suppliers, evaluate technical specifications, and consider cost-effective purchasing strategies. By leveraging experience, expertise, authority, and trust, stakeholders can ensure they choose the best fiberglass sticky mesh for their needs, supporting successful project outcomes and advancing industry standards.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories