2 月 . 01, 2025 04:27 Back to list

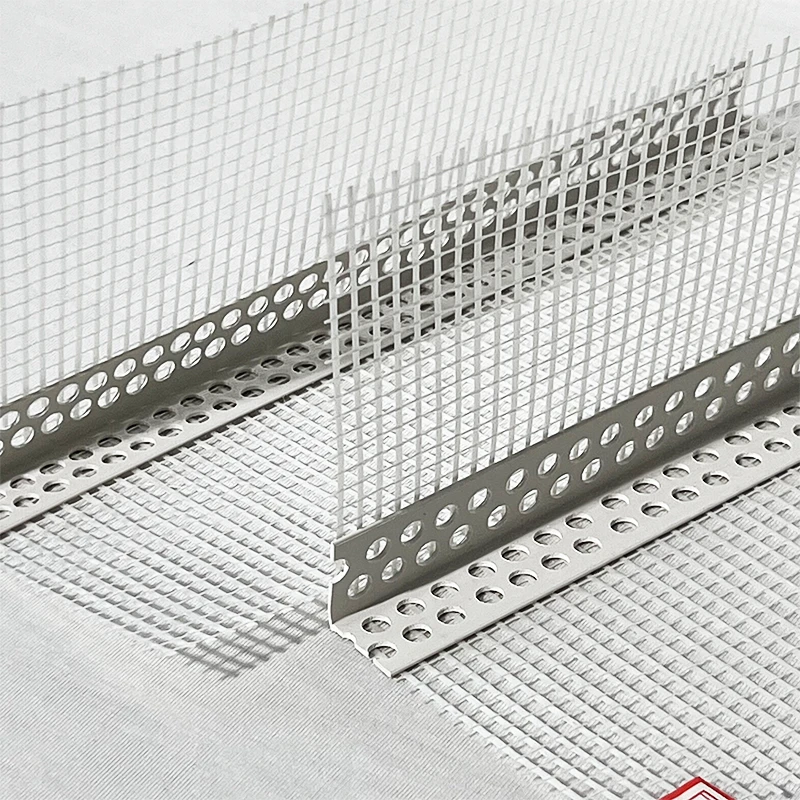

fiberglass wall mesh

Fiberglass sticky mesh products have emerged as an indispensable component in a variety of construction and renovation projects, prized for their unparalleled strength, durability, and versatility. These products, often employed in reinforcing surfaces, preventing cracks, and offering essential structural support, have gained significant traction due to their profound impact on building integrity and longevity.

A deep dive into the expert utilization of fiberglass sticky mesh unveils its authoritative role in enhancing the thermal insulation properties of walls and ceilings. When incorporated within insulation systems, the mesh significantly boosts the overall thermal efficiency, facilitating superior energy conservation. This is especially critical in environments striving for sustainability and reduced carbon footprints. As energy costs continue to soar, property developers and homeowners alike see increased value in investing in advanced solutions that promise energy efficiency and reduced environmental impact. The trustworthiness of fiberglass sticky mesh products is further reinforced by stringent quality controls adhered to by reputable manufacturers. Quality assurance processes ensure consistent product performance, and compliance with international safety standards offers peace of mind to users across various industries. Furthermore, ongoing product innovation driven by research in material sciences continues to advance these products' capabilities, making them safer, more effective, and easier to work with. For seasoned contractors and DIY enthusiasts alike, choosing the right type of fiberglass sticky mesh tailored to specific project requirements is crucial. Equipped with cutting-edge manufacturing insights and extensive field data, industry leaders offer a spectrum of mesh specifications, from varying mesh densities to specialized adhesive formulations. This versatility allows professionals to navigate complex design challenges while maintaining structural integrity and aesthetic appeal. In conclusion, fiberglass sticky mesh products stand as a testament to the progress in modern building materials, characterized by their exceptional strength, adaptability, and comprehensive application range. Those involved in the construction and renovation fields must acquaint themselves with these products' capabilities to make informed decisions that enhance project outcomes. By integrating fiberglass sticky mesh into current practices, the construction industry propels itself toward a future marked by stability, efficiency, and ecological responsibility.

A deep dive into the expert utilization of fiberglass sticky mesh unveils its authoritative role in enhancing the thermal insulation properties of walls and ceilings. When incorporated within insulation systems, the mesh significantly boosts the overall thermal efficiency, facilitating superior energy conservation. This is especially critical in environments striving for sustainability and reduced carbon footprints. As energy costs continue to soar, property developers and homeowners alike see increased value in investing in advanced solutions that promise energy efficiency and reduced environmental impact. The trustworthiness of fiberglass sticky mesh products is further reinforced by stringent quality controls adhered to by reputable manufacturers. Quality assurance processes ensure consistent product performance, and compliance with international safety standards offers peace of mind to users across various industries. Furthermore, ongoing product innovation driven by research in material sciences continues to advance these products' capabilities, making them safer, more effective, and easier to work with. For seasoned contractors and DIY enthusiasts alike, choosing the right type of fiberglass sticky mesh tailored to specific project requirements is crucial. Equipped with cutting-edge manufacturing insights and extensive field data, industry leaders offer a spectrum of mesh specifications, from varying mesh densities to specialized adhesive formulations. This versatility allows professionals to navigate complex design challenges while maintaining structural integrity and aesthetic appeal. In conclusion, fiberglass sticky mesh products stand as a testament to the progress in modern building materials, characterized by their exceptional strength, adaptability, and comprehensive application range. Those involved in the construction and renovation fields must acquaint themselves with these products' capabilities to make informed decisions that enhance project outcomes. By integrating fiberglass sticky mesh into current practices, the construction industry propels itself toward a future marked by stability, efficiency, and ecological responsibility.

Prev:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories