1 月 . 22, 2025 05:17 Back to list

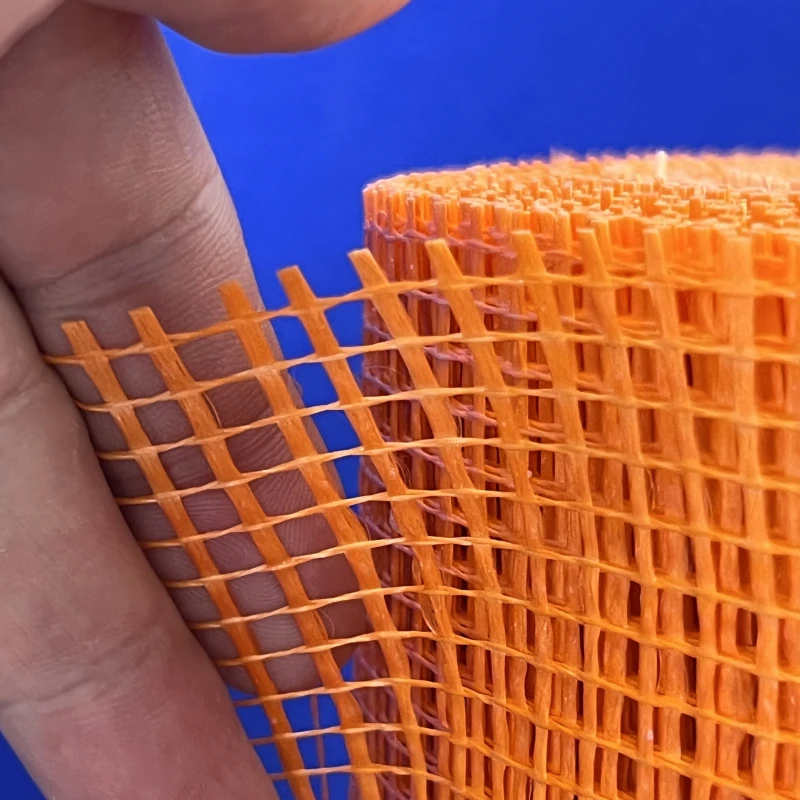

Alkali resistant construction eifs fiber glass mesh rolls

Fibreglass joint tape has become an indispensable tool in the world of construction and home repair, famed for its durability, versatility, and cost-effectiveness. Those who have worked on drywall installations or repairs can attest to the critical role this material plays in ensuring joints between drywall panels are seamless and structurally sound.

In terms of professional endorsement, many construction experts acknowledge fibreglass joint tape's superiority when working on projects requiring a heavy-duty solution. Construction industry veterans such as drywall finishers often choose fibreglass tape for its ability to handle the stress of shifting structures. As buildings settle, particularly in new constructions, the tape remains intact, reducing the maintenance frequency and thereby lowering long-term costs. Reliability is a critical component of trustworthiness, especially in the construction industry where the stakes are often high. The robustness of fibreglass joint tape under various conditions has been extensively documented, contributing to its reputation. Product testing by reputable manufacturers assures quality control, uniformly producing tapes that withstand the physical demands of construction environments. When choosing fibreglass joint tape, it’s crucial to select a product from a reputable manufacturer with a proven track record. Due diligence in researching a brand's credibility, including customer reviews and professional endorsements, ensures that the tape will perform as expected. In conclusion, fibreglass joint tape represents a pivotal advancement in construction materials, combining traditional craftsmanship with modern technology. Experience with its application and adherence to best practices allows for achieving the professional finish expected in today’s competitive building industry. Building authorities and consumer advocates alike recognize fibreglass joint tape not only as a product of choice for quality construction but as a testament to the industry's evolution towards more reliable, efficient, and durable building solutions.

In terms of professional endorsement, many construction experts acknowledge fibreglass joint tape's superiority when working on projects requiring a heavy-duty solution. Construction industry veterans such as drywall finishers often choose fibreglass tape for its ability to handle the stress of shifting structures. As buildings settle, particularly in new constructions, the tape remains intact, reducing the maintenance frequency and thereby lowering long-term costs. Reliability is a critical component of trustworthiness, especially in the construction industry where the stakes are often high. The robustness of fibreglass joint tape under various conditions has been extensively documented, contributing to its reputation. Product testing by reputable manufacturers assures quality control, uniformly producing tapes that withstand the physical demands of construction environments. When choosing fibreglass joint tape, it’s crucial to select a product from a reputable manufacturer with a proven track record. Due diligence in researching a brand's credibility, including customer reviews and professional endorsements, ensures that the tape will perform as expected. In conclusion, fibreglass joint tape represents a pivotal advancement in construction materials, combining traditional craftsmanship with modern technology. Experience with its application and adherence to best practices allows for achieving the professional finish expected in today’s competitive building industry. Building authorities and consumer advocates alike recognize fibreglass joint tape not only as a product of choice for quality construction but as a testament to the industry's evolution towards more reliable, efficient, and durable building solutions.

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories