2 月 . 20, 2025 11:02 Back to list

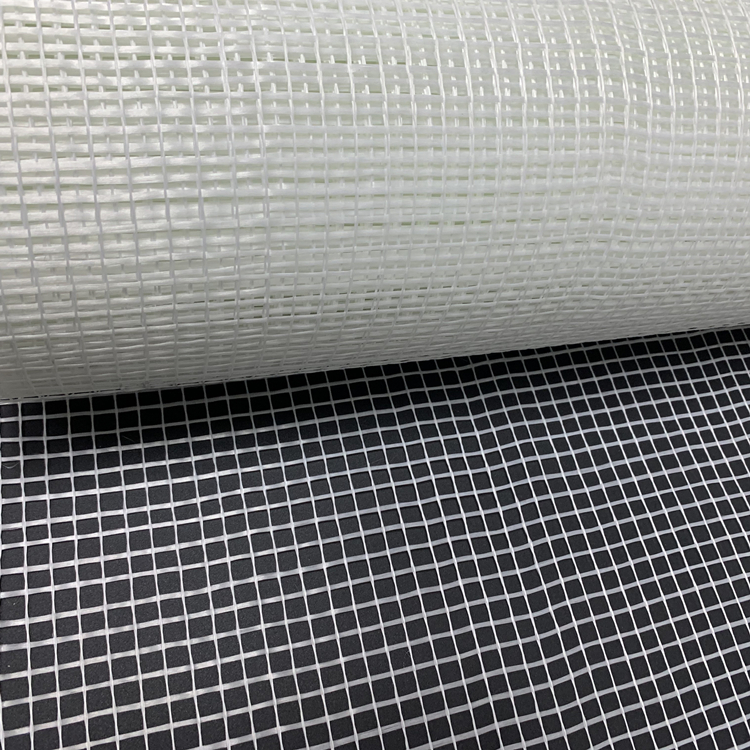

Alkali-resistant fiberglass mesh drywall tape

Fibreglass mesh rolls have become an essential component for various construction and renovation projects. Their versatile applications, from reinforcing concrete surfaces to supporting thermal insulation systems, highlight their necessity in modern building practices. As the demand for these materials grows, understanding their market dynamics is crucial for anyone involved in the trade or use of construction supplies.

Environmental considerations and certifications of compliance add another layer of complexity to the pricing models for fibreglass mesh rolls. As construction regulations increasingly emphasize sustainability, manufacturers have started to adopt greener production methods. These might include utilizing recycled materials or adopting energy-efficient manufacturing processes. While there may be a premium associated with eco-friendly products, many businesses are willing to invest in them to align with market trends and regulatory demands. Certifications, such as ISO standards for environmental management and manufacturing quality, ensure product credibility and reliability, often justifying an elevated price point. Seasonality and market trends also play a part in influencing the pricelist of fibreglass mesh rolls. Construction projects often peak during certain seasons, driving demand and consequently affecting prices. Keeping an eye on market trends, such as shifts towards green building materials and technological innovations in construction, can provide unanticipated insights into future pricing movements. Finally, establishing strong supplier relationships is indispensable for procuring fibreglass mesh rolls at optimal prices. Long-term partnerships encourage competitive pricing structures, bulk purchase discounts, and consistent supply reliability, crucial for maintaining a competitive edge in the market. Businesses should continually evaluate supplier performance to ensure they partner with entities that align with their economic and operational goals. In conclusion, a comprehensive understanding of the factors influencing fibreglass mesh roll pricing can significantly enhance a company's strategic purchasing decisions. By considering material qualities, roll dimensions, regional manufacturing benefits, environmental certifications, market trends, and supplier partnerships, businesses can navigate this market with greater confidence and efficiency. Such informed decision-making not only optimizes procurement but also reinforces a company’s standing in the competitive landscape of construction materials.

Environmental considerations and certifications of compliance add another layer of complexity to the pricing models for fibreglass mesh rolls. As construction regulations increasingly emphasize sustainability, manufacturers have started to adopt greener production methods. These might include utilizing recycled materials or adopting energy-efficient manufacturing processes. While there may be a premium associated with eco-friendly products, many businesses are willing to invest in them to align with market trends and regulatory demands. Certifications, such as ISO standards for environmental management and manufacturing quality, ensure product credibility and reliability, often justifying an elevated price point. Seasonality and market trends also play a part in influencing the pricelist of fibreglass mesh rolls. Construction projects often peak during certain seasons, driving demand and consequently affecting prices. Keeping an eye on market trends, such as shifts towards green building materials and technological innovations in construction, can provide unanticipated insights into future pricing movements. Finally, establishing strong supplier relationships is indispensable for procuring fibreglass mesh rolls at optimal prices. Long-term partnerships encourage competitive pricing structures, bulk purchase discounts, and consistent supply reliability, crucial for maintaining a competitive edge in the market. Businesses should continually evaluate supplier performance to ensure they partner with entities that align with their economic and operational goals. In conclusion, a comprehensive understanding of the factors influencing fibreglass mesh roll pricing can significantly enhance a company's strategic purchasing decisions. By considering material qualities, roll dimensions, regional manufacturing benefits, environmental certifications, market trends, and supplier partnerships, businesses can navigate this market with greater confidence and efficiency. Such informed decision-making not only optimizes procurement but also reinforces a company’s standing in the competitive landscape of construction materials.

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories