2 月 . 18, 2025 00:21 Back to list

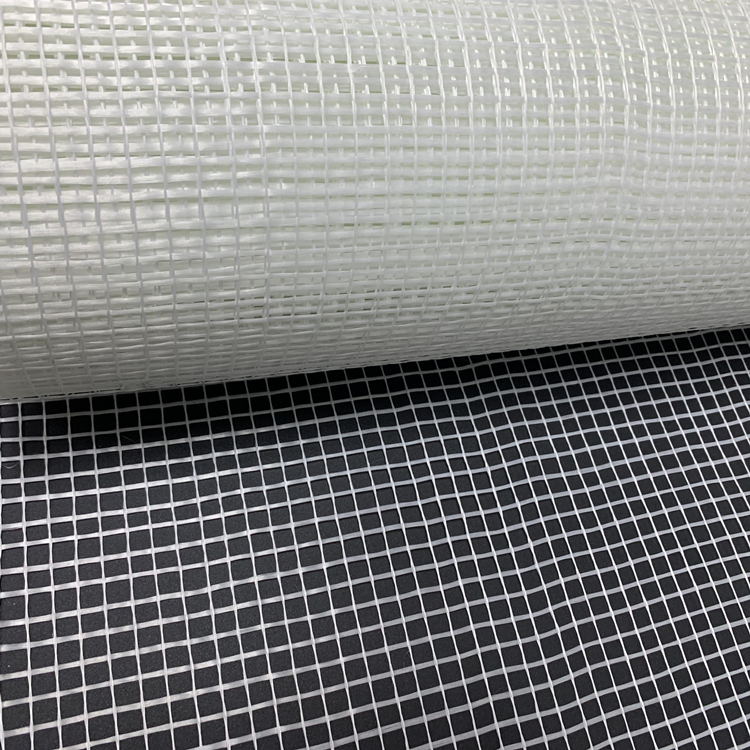

fiberglass wall mesh

In the rapidly evolving construction and renovation industry, selecting the right materials is crucial for ensuring durability and efficiency. One such indispensable material is glass mesh tape, an essential component for wall finishing and crack repair. Understanding the intricacies of glass mesh tape factories reveals insights into the product's quality and reliability, allowing one to make informed decisions for their construction needs.

Trustworthiness is built through consistent delivery of high-quality products. Factory certifications, adhering to international quality standards like ISO and CE, further underscore the reliability of glass mesh tapes manufactured in these facilities. Trust is also established through dedicated customer service, where feedback loops help refine the product offerings based on user experience, ensuring that builders and contractors receive the best possible product for their projects. Furthermore, the alliance of glass mesh tape factories with research institutions and universities fosters innovation in product development. This collaboration results in advanced tape variants that resist mold, mildew, and harsh climatic conditions, offering extended life spans for construction projects. Selecting a reputable glass mesh tape factory can drastically impact the success of a construction endeavor. By choosing factories that prioritize quality, expertise, and sustainability, stakeholders are assured of superior products that contribute to the structural integrity and aesthetic appeal of their projects. In conclusion, the unseen craftsmanship within glass mesh tape factories plays a pivotal role in shaping the modern landscape of construction materials. Their dedication to excellence not only enhances the performance of their products but also champions the cause of sustainable building practices. These factories, with their experience, expertise, authority, and trustworthiness, are indispensable partners for anyone in the construction industry seeking quality and reliability in their building supplies.

Trustworthiness is built through consistent delivery of high-quality products. Factory certifications, adhering to international quality standards like ISO and CE, further underscore the reliability of glass mesh tapes manufactured in these facilities. Trust is also established through dedicated customer service, where feedback loops help refine the product offerings based on user experience, ensuring that builders and contractors receive the best possible product for their projects. Furthermore, the alliance of glass mesh tape factories with research institutions and universities fosters innovation in product development. This collaboration results in advanced tape variants that resist mold, mildew, and harsh climatic conditions, offering extended life spans for construction projects. Selecting a reputable glass mesh tape factory can drastically impact the success of a construction endeavor. By choosing factories that prioritize quality, expertise, and sustainability, stakeholders are assured of superior products that contribute to the structural integrity and aesthetic appeal of their projects. In conclusion, the unseen craftsmanship within glass mesh tape factories plays a pivotal role in shaping the modern landscape of construction materials. Their dedication to excellence not only enhances the performance of their products but also champions the cause of sustainable building practices. These factories, with their experience, expertise, authority, and trustworthiness, are indispensable partners for anyone in the construction industry seeking quality and reliability in their building supplies.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories