12 月 . 03, 2024 16:58 Back to list

mesh fibreglass factory

The Significance of Mesh Fiberglass Factories in Modern Manufacturing

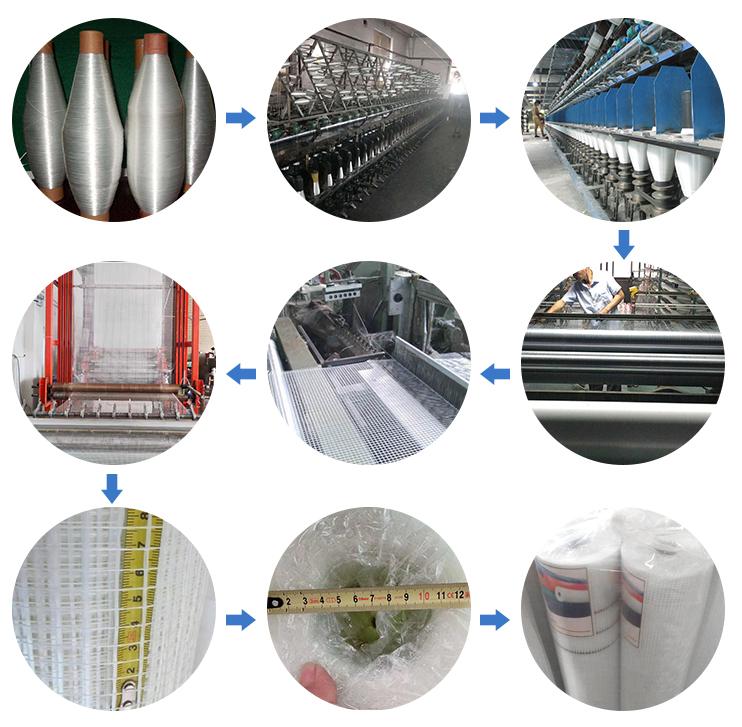

In today's fast-paced world of manufacturing, the demand for lightweight yet durable materials has never been greater. One such material that has gained prominence is mesh fiberglass. Mesh fiberglass is a composite material made from woven fiberglass strands that are bonded with resin, forming a versatile and resilient structure. This article explores the operations and importance of mesh fiberglass factories, highlighting their role in various industries and the benefits they offer.

Mesh fiberglass is renowned for its strength-to-weight ratio, making it an ideal choice for a multitude of applications, particularly in construction, marine, automotive, and aerospace industries. Unlike traditional materials such as metal or wood, mesh fiberglass is resistant to corrosion, UV radiation, and various chemicals. This unique property extends its lifespan, reducing maintenance costs and enhancing sustainability in manufacturing practices.

The Significance of Mesh Fiberglass Factories in Modern Manufacturing

Quality control is a critical aspect of operations in a mesh fiberglass factory. The production line employs various testing methods to ensure that the final product meets industry standards and customer specifications. These tests may include tensile strength assessments, impact resistance evaluations, and moisture absorption tests. By adhering to rigorous quality assurance protocols, manufacturers can guarantee that their mesh fiberglass products deliver optimal performance in their intended applications.

mesh fibreglass factory

One prominent application of mesh fiberglass is in the construction industry. As builders seek lighter and more efficient materials, mesh fiberglass has become a popular alternative to traditional building products. It is commonly used in reinforcing concrete structures, providing superior tensile strength and reducing the risk of cracking. Furthermore, mesh fiberglass is utilized in roofing applications, where its lightweight nature significantly reduces the load on structural components, leading to potential savings in material costs and improved energy efficiency.

In the marine sector, mesh fiberglass has transformed boat manufacturing. With its resistance to water and corrosion, it is an ideal material for constructing hulls and components that are exposed to harsh marine environments. Manufacturers use mesh fiberglass to create lightweight but robust boat structures, enhancing performance and fuel efficiency. Additionally, it allows for greater design flexibility, enabling architects and designers to innovate without compromising strength or safety.

The automotive industry also leverages the benefits of mesh fiberglass. As manufacturers aim to produce lighter vehicles to enhance fuel efficiency and reduce carbon emissions, mesh fiberglass serves as an excellent material for components such as panels, body structures, and interiors. By replacing heavier metals with mesh fiberglass, vehicle manufacturers can achieve significant weight reductions while maintaining the necessary strength and safety standards.

Aerospace applications are another critical area where mesh fiberglass plays a crucial role. With the need for lightweight materials to reduce fuel consumption and increase payload efficiency, mesh fiberglass is used in various components, including radomes, fairings, and structural elements. The material's ability to withstand extreme conditions and its resistance to fatigue make it a preferred choice for many aerospace engineers.

In conclusion, mesh fiberglass factories represent a vital component of modern manufacturing, providing innovative solutions that cater to various industries. By focusing on quality, durability, and performance, these factories contribute to the creation of materials that are not only functional but also sustainable. As technology advances and industries evolve, the demand for mesh fiberglass will likely increase, paving the way for further innovations in materials science and engineering. The future of manufacturing is bright, and mesh fiberglass will undoubtedly play a pivotal role in shaping it.

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024