10 月 . 11, 2023 14:13 Back to list

More about the Fiberglass mesh

What is Fiberglass mesh?

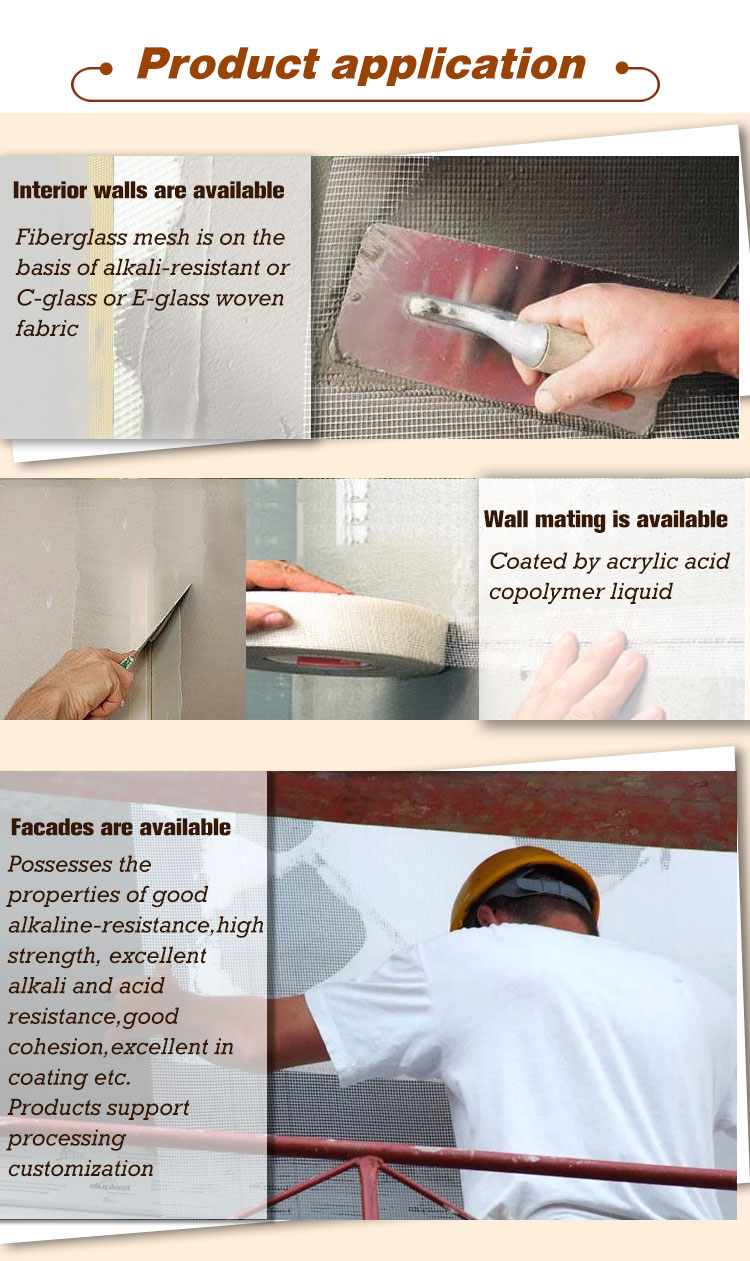

Fiberglass mesh is cheap material that does not burn and is characterized by both low weight and high strength. These properties allow it to be successfully used in the formation of plaster facades, as well as use on internal wall and ceiling surfaces. This material is widely used for fastening the surface layer at the corners of the room.

Most widely used standard fiberglass plater mesh is the density of 145g/m2 and 165g/m2 for exterior cladding and facade work. Resistant to alkalis, does not decompose and will not rust over time, it does not emit toxic and harmful substances, has a high resistance to tearing and stretching, protects the surface from cracking and improves its mechanical strength. Easy to handle and use.

Benefits Fiberglass plaster reinforcing Mesh:

Resistant to alkalis

Does not decompose and will not rust over time.

Does not emit toxic and hazardous substancces.

Helps to overcome stress caused by sudden changes in temperature and humidity.

Has a high resistance to tearing and stretching.

Protects the surface from cracking and improves its mechanical strength.

Fiberglass mesh is easy to hadle and use.

Selecting the Fiberglass Mesh Should Pay Particular Attention to the Following Points:

To determine the resistance to alkalis grid pattern is recommended to put in an alkaline environment for 25 days, and then spend the tensile test. Decrease in strength when it should comply with international standards.

You also need to check the stability of the grid to the tensile stress. For this small piece of mesh is pursed as if molded snowball. After the compressive force stops, the elastic mesh should almost completely restore the original shape.

Technical Parameter of fiberglass mesh(for reference only)

|

Project |

Unit |

140g/m2 |

160g/m2 |

180g/m2 |

200g/m2 |

250g/m2 |

300g/m2 |

|

|

Length |

M/roll |

1400 |

1300 |

1100 |

1000 |

700 |

600 |

|

|

Dicke |

mm |

0.6±0.2 |

0.8±0.2 |

0.9±0.2 |

1.0±0.2 |

1.2±0.2 |

1.5±0.2 |

|

|

Breite |

mm |

1020 |

||||||

|

Shrink rate |

mm |

≤2 |

||||||

|

Moisture content |

% |

≤0.4 |

||||||

|

Eccentricity |

% |

≤±6 |

||||||

|

Tensile streeength |

protrait |

N/5cm |

≥280 |

≥320 |

≥450 |

≥500 |

≥650 |

≥800 |

|

Tansverse<MD> |

N/5cm |

≥280 |

≥300 |

≥400 |

≥450 |

≥550 |

≥800 |

|

|

Elongation at break |

protrait |

% |

18-25 |

20-25 |

25-35 |

30-40 |

30-40 |

40-50 |

|

Tansverse<MD> |

% |

18-25 |

20-25 |

25-35 |

30-40 |

30-40 |

40-50 |

|

|

Tear strength |

protrait |

N/5cm |

≥70 |

≥100 |

≥100 |

≥120 |

≥160 |

≥250 |

|

Tansverse<MD> |

N/5cm |

≥70 |

≥80 |

≥100 |

≥120 |

≥160 |

≥250 |

|

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024