1 月 . 20, 2025 06:15 Back to list

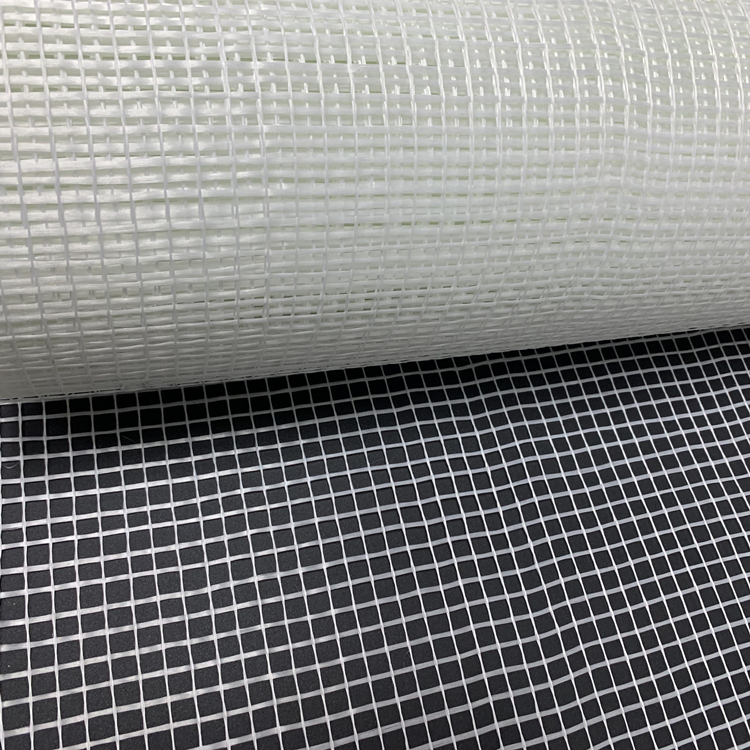

plasterboard fibreglass joint tape

Navigating the complexities of drywall installation can be daunting for both novices and seasoned contractors, but selecting the right materials is crucial to success. One product that stands out in the world of drywall finishing is plasterboard fibreglass joint tape. This product has transformed many projects with its superior reinforcement capabilities and ease of use. Here, we delve into the experience of utilizing plasterboard fibreglass joint tape, aiming to shed light on its benefits, applications, and best practices for ensuring professional results.

A real advantage of using fibreglass over paper tape is its resilience to water and high humidity. In spaces like bathrooms or kitchens, where moisture is a constant concern, choosing fibreglass ensures the longevity of the drywall finish. Mold growth, a common issue with traditional materials, is significantly minimized, granting homeowners peace of mind and reducing long-term maintenance costs. Despite its myriad benefits, some skepticism persists regarding the fibreglass tape’s performance in comparison to paper tape, especially related to finishing texture and compatibility with different types of joint compounds. However, ongoing studies and professional testimonials often showcase that when used correctly, fibreglass tape does not compromise on aesthetics and integrates well with most products available in the market. Given the ongoing advancements in construction materials, fibreglass joint tape exemplifies the seamless blending of technology and practicality. It represents a forward leap in enhancing the durability and efficiency of drywall installations. Professional contractors and DIY enthusiasts alike are increasingly opting for fibreglass tape, driven not only by its inherent properties but also by a growing portfolio of successful applications documented across varied climatic conditions and structural environments. In essence, plasterboard fibreglass joint tape offers a compelling alternative to traditional materials, combining practicality with innovative features. For those in the construction domain striving for excellence, adopting fibreglass tape can elevate the quality of work, ensuring durability and customer satisfaction. It's a testament to modern advancements in construction materials, reinforcing the importance of choosing the right products to complement skill and craftsmanship.

A real advantage of using fibreglass over paper tape is its resilience to water and high humidity. In spaces like bathrooms or kitchens, where moisture is a constant concern, choosing fibreglass ensures the longevity of the drywall finish. Mold growth, a common issue with traditional materials, is significantly minimized, granting homeowners peace of mind and reducing long-term maintenance costs. Despite its myriad benefits, some skepticism persists regarding the fibreglass tape’s performance in comparison to paper tape, especially related to finishing texture and compatibility with different types of joint compounds. However, ongoing studies and professional testimonials often showcase that when used correctly, fibreglass tape does not compromise on aesthetics and integrates well with most products available in the market. Given the ongoing advancements in construction materials, fibreglass joint tape exemplifies the seamless blending of technology and practicality. It represents a forward leap in enhancing the durability and efficiency of drywall installations. Professional contractors and DIY enthusiasts alike are increasingly opting for fibreglass tape, driven not only by its inherent properties but also by a growing portfolio of successful applications documented across varied climatic conditions and structural environments. In essence, plasterboard fibreglass joint tape offers a compelling alternative to traditional materials, combining practicality with innovative features. For those in the construction domain striving for excellence, adopting fibreglass tape can elevate the quality of work, ensuring durability and customer satisfaction. It's a testament to modern advancements in construction materials, reinforcing the importance of choosing the right products to complement skill and craftsmanship.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories