2 月 . 11, 2025 19:38 Back to list

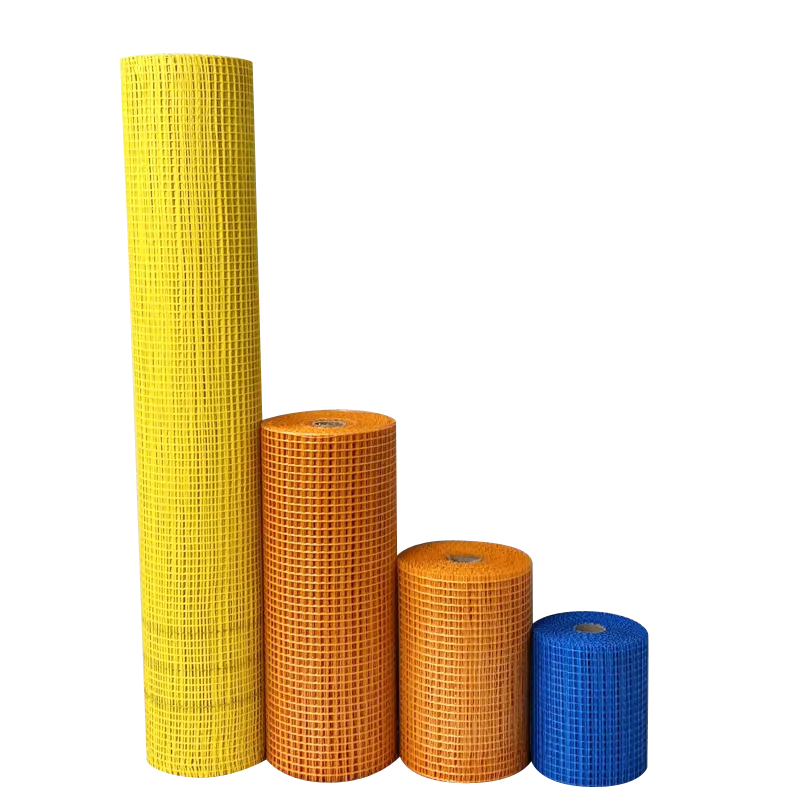

plasterboard fibreglass joint tape factory

Navigating the complex world of plasterboard installation can be challenging, especially when it comes to the critical component of joint reinforcement. One product that has revolutionized this aspect of construction is fiberglass joint tape manufactured in specialized factories. This article delves into the intricate dynamics of how such factories operate, offering a unique glimpse into their impact on construction projects worldwide.

Quality control is another critical aspect where these factories exhibit authority. Each batch of fiberglass joint tape undergoes rigorous testing to ensure it meets international safety and quality standards. These tests often simulate real-world conditions, subjecting the tapes to stress tests that mimic expansion, contraction, and exposure to moisture. By guaranteeing that every roll leaving the factory withstands these trials, manufacturers instill confidence in their products’ performance, enhancing their trustworthiness among users. Sustainability also plays a significant role in the production ethos of modern fiberglass joint tape factories. Many manufacturers are shifting towards eco-friendly production methods, reducing their carbon footprint through energy-efficient processes and recyclable packaging. By prioritizing sustainability, these factories not only contribute to environmental conservation but also align with the growing consumer expectation for green building materials. When evaluating the importance of these factories, one must consider the broader implications of their innovations and quality assurance on construction quality and efficiency. High-quality fiberglass joint tape reduces the likelihood of repair and maintenance, delivering long-term economic benefits to builders and homeowners alike. Moreover, the product's reliability aids in faster project completions, boosting productivity and ensuring adherence to project timelines. In conclusion, the specialized factories producing plasterboard fiberglass joint tape are essential to the construction industry, combining cutting-edge technology with expert craftsmanship to deliver products that enhance building efficiency, durability, and sustainability. These facilities represent a confluence of experience, expertise, authority, and trustworthiness, making them indispensable contributors to modern architectural excellence. As the demand for high-quality construction materials continues to rise, these manufacturers are poised to lead with innovation and integrity, shaping the future of construction across the globe.

Quality control is another critical aspect where these factories exhibit authority. Each batch of fiberglass joint tape undergoes rigorous testing to ensure it meets international safety and quality standards. These tests often simulate real-world conditions, subjecting the tapes to stress tests that mimic expansion, contraction, and exposure to moisture. By guaranteeing that every roll leaving the factory withstands these trials, manufacturers instill confidence in their products’ performance, enhancing their trustworthiness among users. Sustainability also plays a significant role in the production ethos of modern fiberglass joint tape factories. Many manufacturers are shifting towards eco-friendly production methods, reducing their carbon footprint through energy-efficient processes and recyclable packaging. By prioritizing sustainability, these factories not only contribute to environmental conservation but also align with the growing consumer expectation for green building materials. When evaluating the importance of these factories, one must consider the broader implications of their innovations and quality assurance on construction quality and efficiency. High-quality fiberglass joint tape reduces the likelihood of repair and maintenance, delivering long-term economic benefits to builders and homeowners alike. Moreover, the product's reliability aids in faster project completions, boosting productivity and ensuring adherence to project timelines. In conclusion, the specialized factories producing plasterboard fiberglass joint tape are essential to the construction industry, combining cutting-edge technology with expert craftsmanship to deliver products that enhance building efficiency, durability, and sustainability. These facilities represent a confluence of experience, expertise, authority, and trustworthiness, making them indispensable contributors to modern architectural excellence. As the demand for high-quality construction materials continues to rise, these manufacturers are poised to lead with innovation and integrity, shaping the future of construction across the globe.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories