2 月 . 11, 2025 22:10 Back to list

plasterboard fibreglass joint tape manufacturers

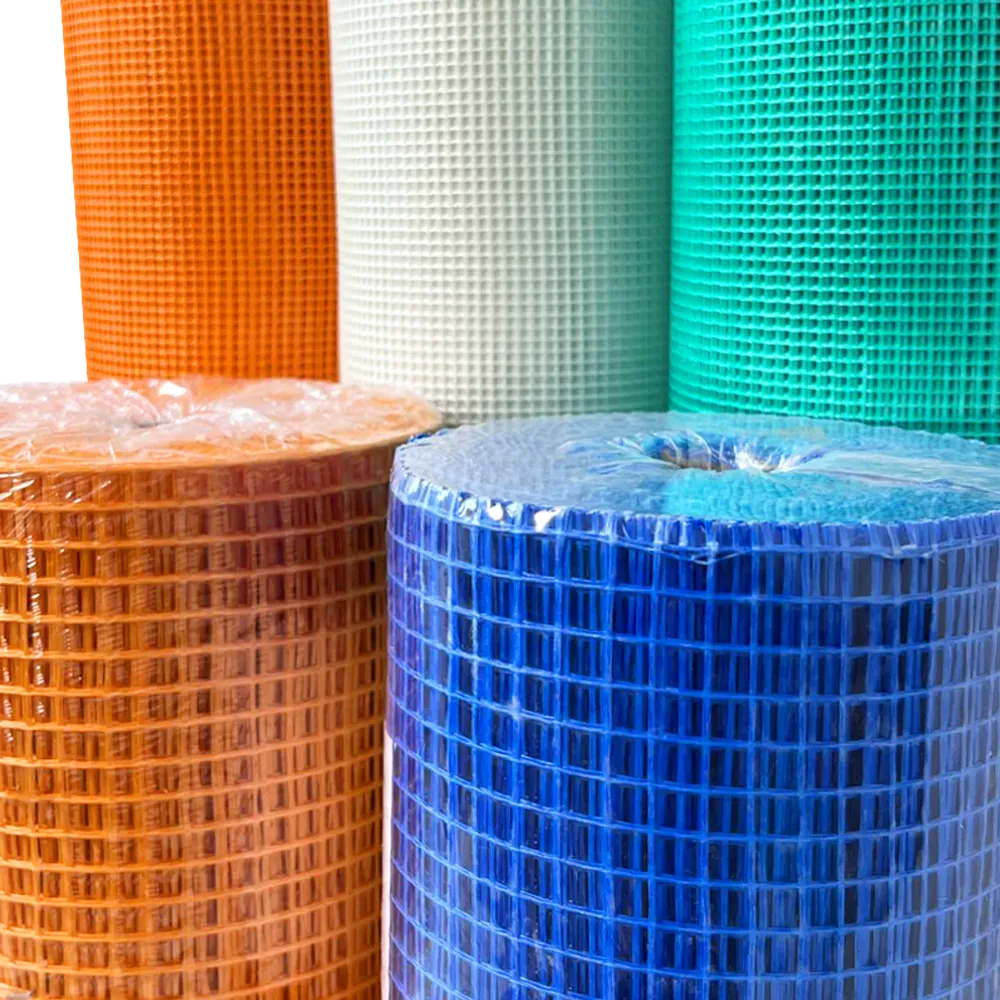

In the dynamic world of construction materials, few products have maintained their relevance and continued to evolve as effectively as plasterboard fiberglass joint tape. This essential component in wall and ceiling applications plays a critical role in ensuring smooth, seamless finishes that are both durable and aesthetically pleasing. With the rise in demand for robust construction materials, several manufacturers have emerged as leaders in the production of high-quality plasterboard fiberglass joint tape, each bringing unique innovations to the table.

When assessing manufacturer authority and trustworthiness, industry certifications and client reviews play a pivotal role. Reputable manufacturers undergo rigorous testing processes to acquire certifications from construction and safety standard organizations. Such certifications not only affirm the quality of their products but also build trust with distributors and end-users. Furthermore, positive testimonials and endorsements from prominent construction companies provide additional assurance of reliability. Another aspect that enhances both the expertise and trustworthiness of a manufacturer is customer support. Providing comprehensive guidance on the application and optimal use of plasterboard fiberglass joint tape reflects an understanding of customer needs and a commitment to positive user experience. Leading manufacturers often offer tutorials, workshops, and personalized support to help construction professionals achieve the best results. This level of service reinforces long-term relationships with clients and positions manufacturers as partners in innovation and efficiency. In conclusion, choosing the right plasterboard fiberglass joint tape manufacturer requires careful consideration of various factors including product durability, sustainability, manufacturing expertise, and company reputation. The leading manufacturers distinguish themselves by combining high-quality materials with cutting-edge production techniques and outstanding customer service. As the construction industry continues to evolve, these manufacturers are well-positioned to meet the demands of modern building projects, delivering products that not only meet but exceed expectations. With continued focus on innovation and sustainability, they ensure that plasterboard fiberglass joint tape remains a vital tool in construction for years to come.

When assessing manufacturer authority and trustworthiness, industry certifications and client reviews play a pivotal role. Reputable manufacturers undergo rigorous testing processes to acquire certifications from construction and safety standard organizations. Such certifications not only affirm the quality of their products but also build trust with distributors and end-users. Furthermore, positive testimonials and endorsements from prominent construction companies provide additional assurance of reliability. Another aspect that enhances both the expertise and trustworthiness of a manufacturer is customer support. Providing comprehensive guidance on the application and optimal use of plasterboard fiberglass joint tape reflects an understanding of customer needs and a commitment to positive user experience. Leading manufacturers often offer tutorials, workshops, and personalized support to help construction professionals achieve the best results. This level of service reinforces long-term relationships with clients and positions manufacturers as partners in innovation and efficiency. In conclusion, choosing the right plasterboard fiberglass joint tape manufacturer requires careful consideration of various factors including product durability, sustainability, manufacturing expertise, and company reputation. The leading manufacturers distinguish themselves by combining high-quality materials with cutting-edge production techniques and outstanding customer service. As the construction industry continues to evolve, these manufacturers are well-positioned to meet the demands of modern building projects, delivering products that not only meet but exceed expectations. With continued focus on innovation and sustainability, they ensure that plasterboard fiberglass joint tape remains a vital tool in construction for years to come.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories