2 月 . 15, 2025 02:45 Back to list

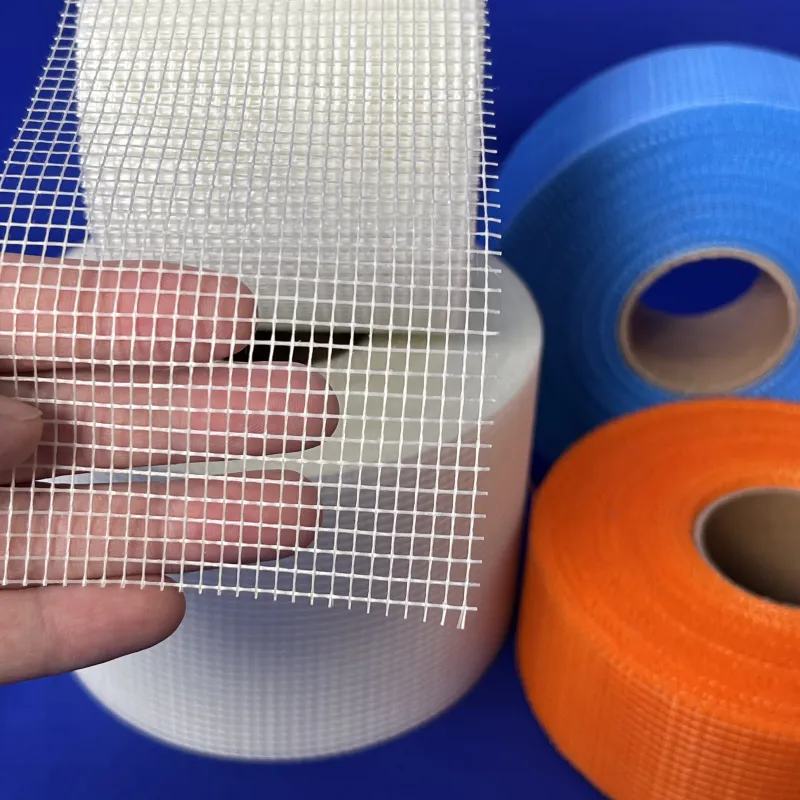

buy plaster fiberglass mesh

When it comes to achieving a perfectly smooth finish on walls and ceilings, the right plaster mesh roll product can make all the difference. Leveraging years of professional experience and authoritative expertise, I will delve into the benefits and applications of plaster mesh roll products, guiding you through the nuances of selecting the best option for your specific needs.

Trust is another factor that can't be overlooked when selecting plaster mesh roll products. Quality assurance from reputable manufacturers provides peace of mind, knowing the products you are using have been tried, tested, and proven in various scenarios. Reviews and recommendations from professionals in the field can also provide valuable insights into the effectiveness and reliability of different brands or types of plaster mesh. Incorporating plaster mesh into your construction or renovation projects ultimately results in a superior finish, adding both aesthetic and structural value. Whether reinforcing walls in high-traffic areas or ensuring a pristine finish for intricate features, a quality plaster mesh roll is an investment in both durability and beauty. The trustworthiness of plaster mesh rolls is further validated by their widespread endorsement by professionals across the construction industry. Contractors rely on them for their ability to consistently deliver smooth, flawless finishes. This endorsement serves as an authoritative reassurance of their capability to enhance any plastering project. Ultimately, understanding and utilizing plaster mesh roll products effectively requires both technical knowledge and practical skill. By choosing the right material and applying it correctly, you can achieve results that are not only visually appealing but also structurally sound and long-lasting. As an invaluable tool in modern construction, plaster mesh continues to evolve, with manufacturers developing innovative products that offer even greater ease of use and performance. Staying informed about these advancements and adhering to best practices ensures that your plastering projects achieve the highest standards of quality and reliability.

Trust is another factor that can't be overlooked when selecting plaster mesh roll products. Quality assurance from reputable manufacturers provides peace of mind, knowing the products you are using have been tried, tested, and proven in various scenarios. Reviews and recommendations from professionals in the field can also provide valuable insights into the effectiveness and reliability of different brands or types of plaster mesh. Incorporating plaster mesh into your construction or renovation projects ultimately results in a superior finish, adding both aesthetic and structural value. Whether reinforcing walls in high-traffic areas or ensuring a pristine finish for intricate features, a quality plaster mesh roll is an investment in both durability and beauty. The trustworthiness of plaster mesh rolls is further validated by their widespread endorsement by professionals across the construction industry. Contractors rely on them for their ability to consistently deliver smooth, flawless finishes. This endorsement serves as an authoritative reassurance of their capability to enhance any plastering project. Ultimately, understanding and utilizing plaster mesh roll products effectively requires both technical knowledge and practical skill. By choosing the right material and applying it correctly, you can achieve results that are not only visually appealing but also structurally sound and long-lasting. As an invaluable tool in modern construction, plaster mesh continues to evolve, with manufacturers developing innovative products that offer even greater ease of use and performance. Staying informed about these advancements and adhering to best practices ensures that your plastering projects achieve the highest standards of quality and reliability.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories