2 月 . 18, 2025 12:02 Back to list

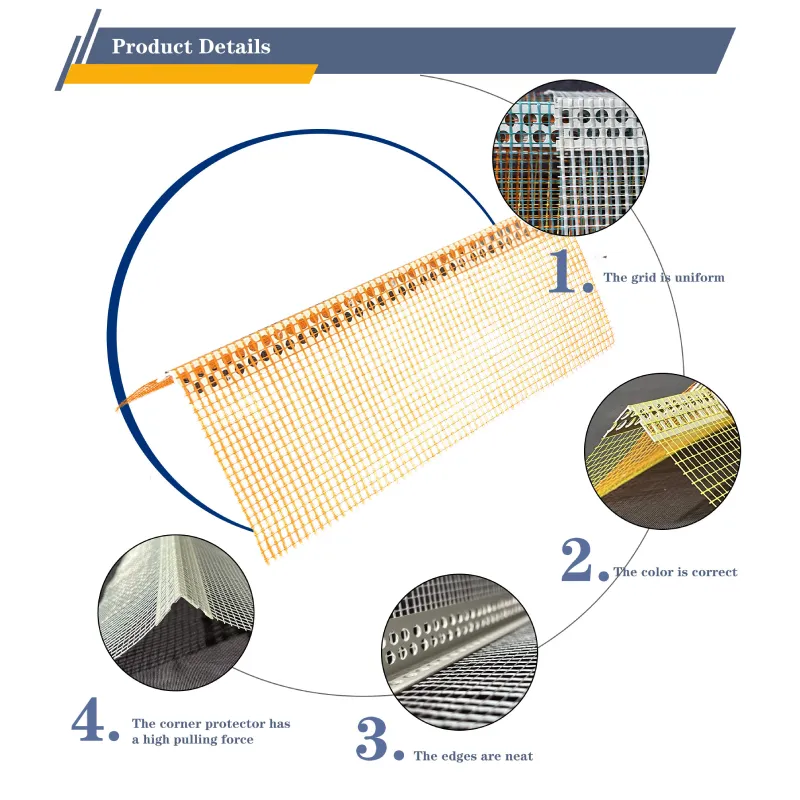

fiberglass wall mesh

In the world of modern construction and architecture, the importance of quality finishing materials cannot be overstated. Plaster net factories have emerged as pivotal players in this sector, offering products that not only enhance the aesthetic appeal of structures but also contribute to their durability and functionality.

Practical experience with plaster net products demonstrates their versatility and effectiveness in diverse applications. From residential homes to large commercial structures, plaster mesh plays a critical role in reinforcing plaster layers, preventing cracking, and enhancing fire resistance. Furthermore, fiberglass options are increasingly popular in applications requiring higher flexibility and resistance to corrosion, making them ideal for projects in coastal or highly humid environments. The expertise of plaster net factories extends beyond mere production; these companies often provide valuable support services, including technical consultancy for architects and builders. This consultative approach helps in selecting the appropriate type and grade of plaster net for specific projects, ensuring optimal results and long-term satisfaction. Additionally, many factories offer custom solutions tailored to unique project specifications, further solidifying their authoritative stance in the industry. Innovations in plaster net manufacturing continue to propel the industry forward. Recent advancements have led to the development of eco-friendly materials, thereby aligning with global sustainability goals. By reducing carbon footprints and promoting the use of recycled materials, leading plaster net factories are not only enhancing the structural integrity of constructions but also contributing positively to the environment. In summary, the role of plaster net factories in the construction industry is multifaceted, driven by expertise, commitment to quality, and a dedication to fostering trust among stakeholders. These factories are essential in ensuring that construction projects not only meet aesthetic expectations but also stand the test of time and environmental challenges. As demand for sustainable and reliable construction solutions grows, plaster net factories continue to innovate and adapt, securing their position as vital contributors to the built environment.

Practical experience with plaster net products demonstrates their versatility and effectiveness in diverse applications. From residential homes to large commercial structures, plaster mesh plays a critical role in reinforcing plaster layers, preventing cracking, and enhancing fire resistance. Furthermore, fiberglass options are increasingly popular in applications requiring higher flexibility and resistance to corrosion, making them ideal for projects in coastal or highly humid environments. The expertise of plaster net factories extends beyond mere production; these companies often provide valuable support services, including technical consultancy for architects and builders. This consultative approach helps in selecting the appropriate type and grade of plaster net for specific projects, ensuring optimal results and long-term satisfaction. Additionally, many factories offer custom solutions tailored to unique project specifications, further solidifying their authoritative stance in the industry. Innovations in plaster net manufacturing continue to propel the industry forward. Recent advancements have led to the development of eco-friendly materials, thereby aligning with global sustainability goals. By reducing carbon footprints and promoting the use of recycled materials, leading plaster net factories are not only enhancing the structural integrity of constructions but also contributing positively to the environment. In summary, the role of plaster net factories in the construction industry is multifaceted, driven by expertise, commitment to quality, and a dedication to fostering trust among stakeholders. These factories are essential in ensuring that construction projects not only meet aesthetic expectations but also stand the test of time and environmental challenges. As demand for sustainable and reliable construction solutions grows, plaster net factories continue to innovate and adapt, securing their position as vital contributors to the built environment.

Prev:

Next:

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories