1 月 . 28, 2025 00:58 Back to list

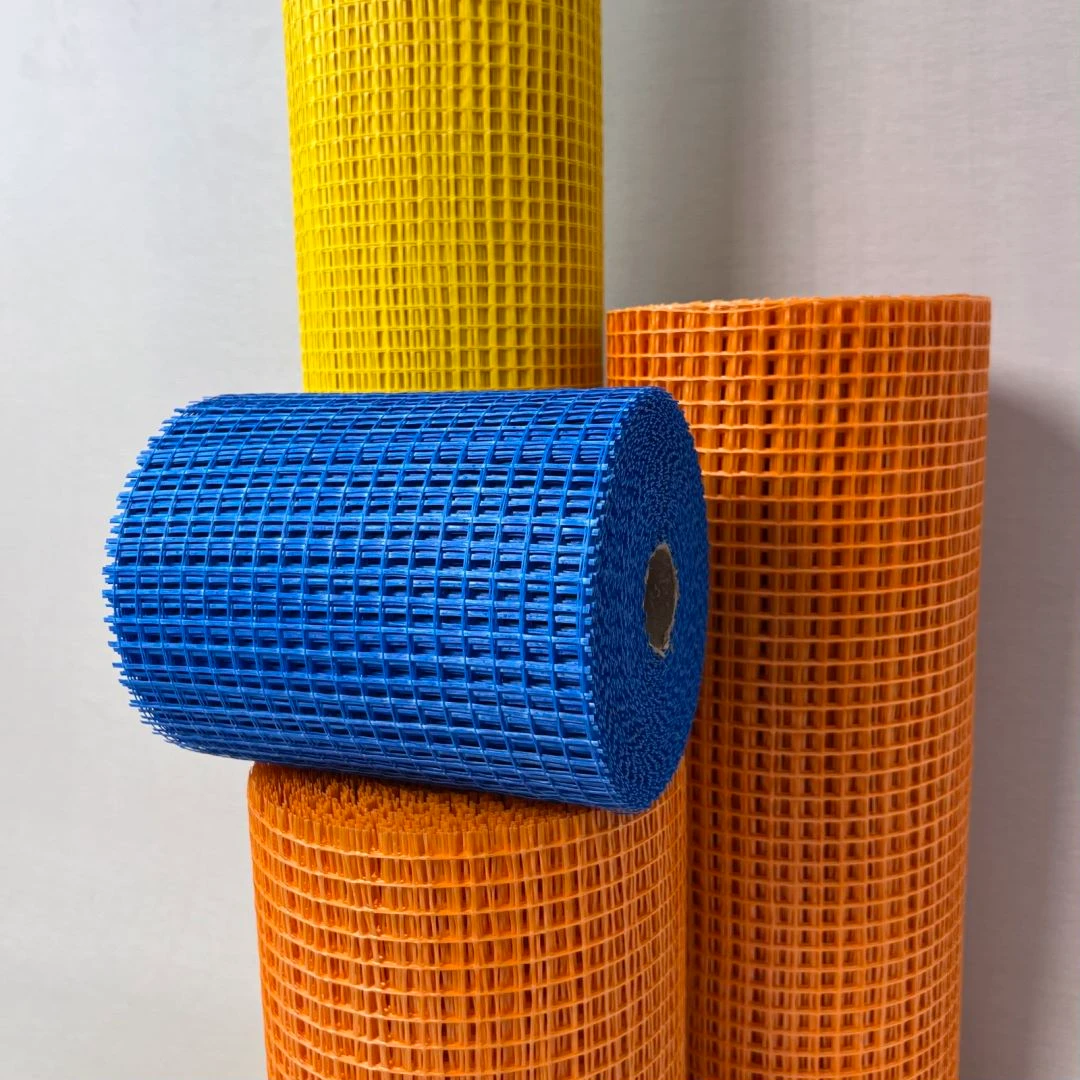

pvc corner bead with fiberglass mesh manufacturer

PVC corner beads with fiberglass mesh have rapidly emerged as indispensable components in modern construction, particularly noted for their role in enhancing the durability and finish quality of plaster and stucco applications. As a manufacturer of these specialized construction materials, it is crucial to understand not only the production intricacies but also the broader market dynamics that inform best practices and innovation.

Providing an encompassing customer experience is another critical factor. Manufacturers should offer comprehensive guides on installation and best practices. By enabling clients and on-field workers with extensive knowledge, the efficacy of the products in real-world applications is enhanced. In addition to user manuals, video tutorials and dedicated support lines can significantly elevate customer satisfaction. Staying abreast with technological advancements and market trends is vital for product evolution. There is a growing trend towards green building materials, and as an innovative manufacturer, exploring eco-friendly variants of PVC corner beads with minimal environmental impact can attract environmentally conscious builders. Implementing sustainable practices not only aligns with global environmental goals but also enhances brand reputation. Exclusive collaborations and partnerships with construction firms and architects can serve as a dynamic avenue for growth. By working closely with industry experts, manufacturers can gain insights into emerging requirements and upcoming design trends, thereby tailoring products to meet future demands. In summary, being a leading manufacturer of PVC corner beads with fiberglass mesh encompasses an intricate mix of technical expertise, stringent quality assurance, environment-conscious production, and robust customer support. As these elements converge, the end result is a product line that not only meets but exceeds industry standards, ultimately contributing to the integrity and visual appeal of our built environments.

Providing an encompassing customer experience is another critical factor. Manufacturers should offer comprehensive guides on installation and best practices. By enabling clients and on-field workers with extensive knowledge, the efficacy of the products in real-world applications is enhanced. In addition to user manuals, video tutorials and dedicated support lines can significantly elevate customer satisfaction. Staying abreast with technological advancements and market trends is vital for product evolution. There is a growing trend towards green building materials, and as an innovative manufacturer, exploring eco-friendly variants of PVC corner beads with minimal environmental impact can attract environmentally conscious builders. Implementing sustainable practices not only aligns with global environmental goals but also enhances brand reputation. Exclusive collaborations and partnerships with construction firms and architects can serve as a dynamic avenue for growth. By working closely with industry experts, manufacturers can gain insights into emerging requirements and upcoming design trends, thereby tailoring products to meet future demands. In summary, being a leading manufacturer of PVC corner beads with fiberglass mesh encompasses an intricate mix of technical expertise, stringent quality assurance, environment-conscious production, and robust customer support. As these elements converge, the end result is a product line that not only meets but exceeds industry standards, ultimately contributing to the integrity and visual appeal of our built environments.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories