1 月 . 26, 2025 04:27 Back to list

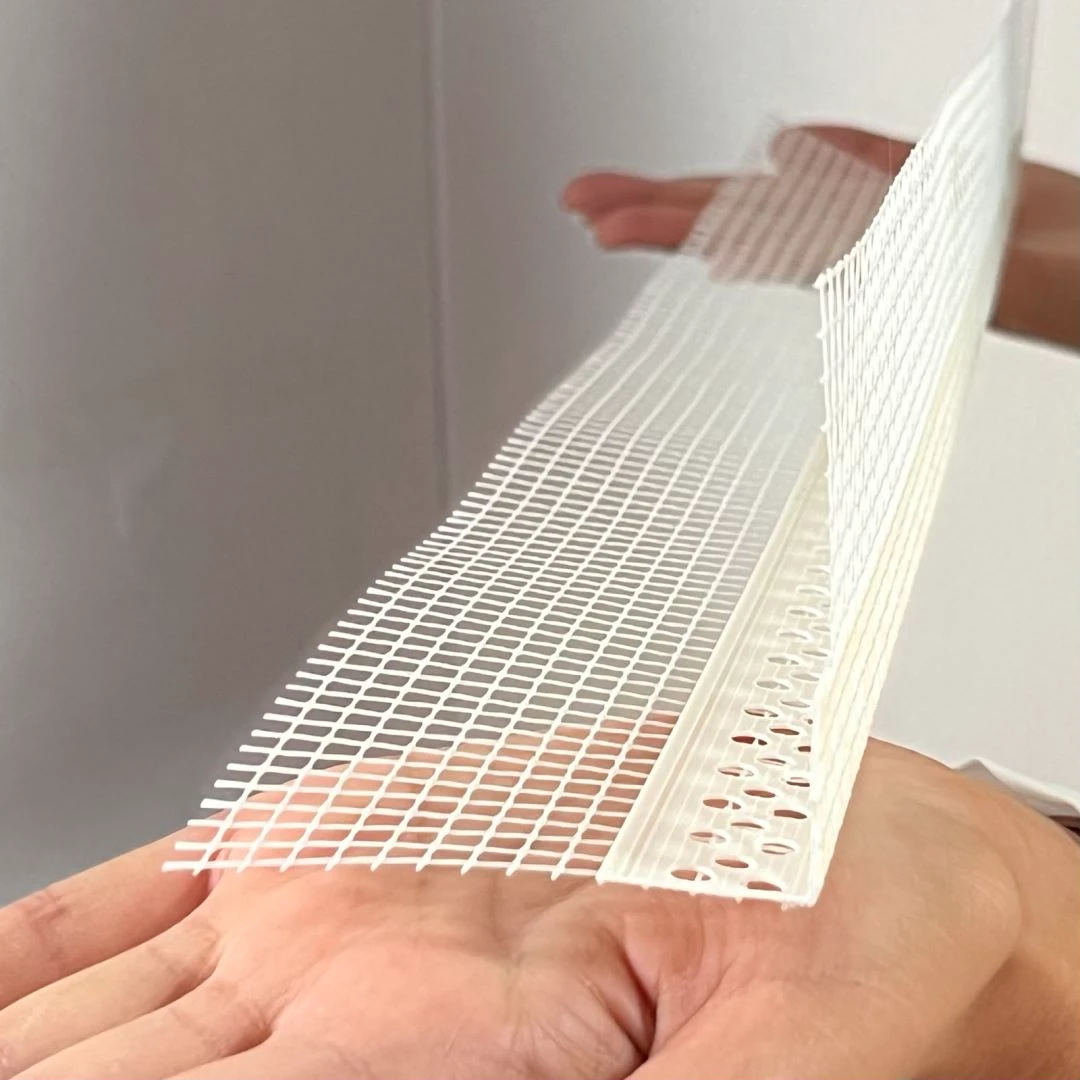

self adhesive fibreglass mesh manufacturers

In the dynamic and ever-evolving construction and renovation industry, self-adhesive fiberglass mesh stands out as a crucial component that offers unmatched reinforcement across various applications. An in-depth understanding of this product, as well as insights into the leading manufacturers, enhances one's ability to make informed purchasing decisions.

Another factor to consider is the environmental responsibility of the manufacturer. In an era where sustainability is pivotal, manufacturers that employ eco-friendly production practices and use recyclable materials align with the values of conscious consumers and businesses. This alignment not only enhances the manufacturer's credibility but also contributes to more sustainable construction practices. In the competitive landscape of self-adhesive fiberglass mesh production, manufacturers that provide comprehensive solutions—ranging from small-scale to large-scale projects—demonstrate their proficiency and flexibility. Their ability to supply mesh in various widths, lengths, and colors ensures they cater to diverse customer requirements, reinforcing their position as industry leaders. Collaborations with these reputable manufacturers allow industry professionals to leverage advanced products that simplify installation processes and provide enduring results. These collaborations are bolstered by strong distribution networks, which ensure timely delivery and consistent availability of products even in challenging supply chain climates. For those new to selecting self-adhesive fiberglass mesh manufacturers, connecting with industry experts and reading peer reviews can provide valuable insights. Word-of-mouth recommendations and testimonials from experienced contractors and builders often reveal nuances about the product's performance that aren't captured in technical specifications. In summary, the journey of selecting a self-adhesive fiberglass mesh manufacturer is not merely about evaluating the product but involves a comprehensive inquiry into the manufacturer's ethos, innovation capability, and service excellence. A focus on these aspects guarantees that one secures a product that meets the highest standards of quality and performance, contributing significantly to the success and longevity of construction projects.

Another factor to consider is the environmental responsibility of the manufacturer. In an era where sustainability is pivotal, manufacturers that employ eco-friendly production practices and use recyclable materials align with the values of conscious consumers and businesses. This alignment not only enhances the manufacturer's credibility but also contributes to more sustainable construction practices. In the competitive landscape of self-adhesive fiberglass mesh production, manufacturers that provide comprehensive solutions—ranging from small-scale to large-scale projects—demonstrate their proficiency and flexibility. Their ability to supply mesh in various widths, lengths, and colors ensures they cater to diverse customer requirements, reinforcing their position as industry leaders. Collaborations with these reputable manufacturers allow industry professionals to leverage advanced products that simplify installation processes and provide enduring results. These collaborations are bolstered by strong distribution networks, which ensure timely delivery and consistent availability of products even in challenging supply chain climates. For those new to selecting self-adhesive fiberglass mesh manufacturers, connecting with industry experts and reading peer reviews can provide valuable insights. Word-of-mouth recommendations and testimonials from experienced contractors and builders often reveal nuances about the product's performance that aren't captured in technical specifications. In summary, the journey of selecting a self-adhesive fiberglass mesh manufacturer is not merely about evaluating the product but involves a comprehensive inquiry into the manufacturer's ethos, innovation capability, and service excellence. A focus on these aspects guarantees that one secures a product that meets the highest standards of quality and performance, contributing significantly to the success and longevity of construction projects.

Latest news

-

Why Fiberglass Mesh Tape Is the Contractor’s New Best FriendNewsOct.30,2024

-

The Role of Fiberglass Mesh Tape in Tile and Plaster ApplicationsNewsOct.30,2024

-

Humidity-Resistant & Mold-Preventive: Why Fiberglass Mesh Tape is Ideal for High-Moisture AreasNewsOct.30,2024

-

From Patching to Reinforcement: How Fiberglass Mesh Tape Is Changing the Face of ConstructionNewsOct.30,2024

-

Why Fiberglass Mesh Tape is the Sustainable Choice for Safer HomesNewsOct.30,2024

-

Save on Maintenance Costs with Fiberglass Mesh Reinforced StructuresNewsOct.25,2024

Products categories